Views: 6 Author: Site Editor Publish Time: 2025-09-11 Origin: Site

Shanghai Zhucheng Pipe Fitting Manufacturing Co., Ltd., as a top of supplier in the field of domestic pipeline fittings, has been deeply involved in the production and sales of pipelines and fittings for many years. We provide a full range of pipeline fittings products including steel pipes, flanges, fittings, bolts, gaskets, etc. for customers in the petrochemical, nuclear power, water treatment, pharmaceutical and other fields at home and abroad. With strict quality control, efficient delivery capabilities, and meticulous professional services, we have won unanimous recognition from global customers and become a long-term trusted partner for many enterprises.

ASTM A182 F316L WN flange is one of our main products. Excellent corrosion resistance can effectively avoid the risk of leakage in pipeline systems caused by corrosion; Stable mechanical performance can maintain structural stability in harsh environments, laying a solid foundation for the long-term safe operation of the system.

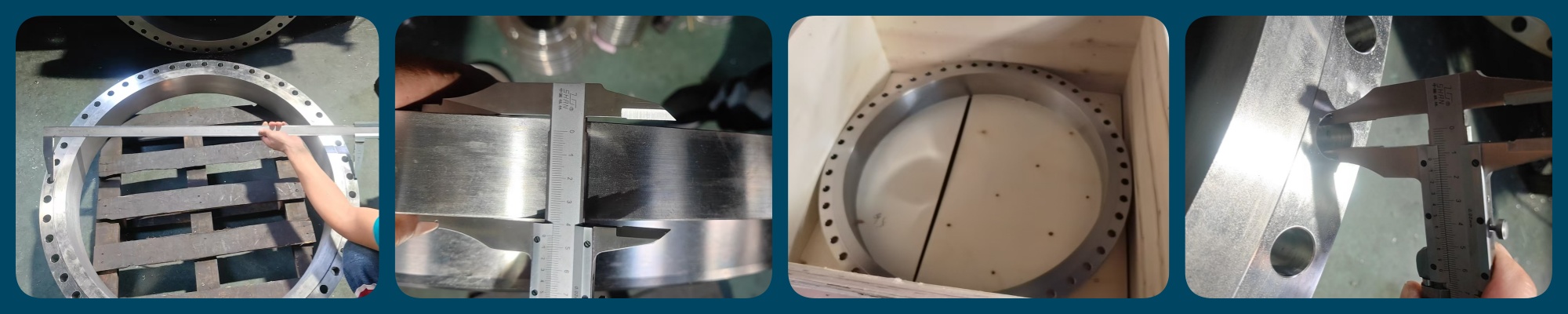

Not long ago, the company ordered a batch of ASME B16.47 Series B large-diameter weld neck flanges from a long-term customer in Shanghai, all of which are made of ASTM A182 F316L material.

Size specifications: The size of this batch of ASTM A182 F316L weld neck flange orders is DN 800, which belongs to large-diameter flanges. Compared with conventional small-diameter flanges, its processing accuracy requirements are higher. Key dimensions such as flange outer diameter, bolt hole center circle diameter, and sealing surface flatness need to be strictly controlled to ensure compatibility with the customer's existing pipeline system;

Pressure rating: Adopting Class 150 pressure rating, combined with the mechanical properties of F316L material, it has stable pressure bearing capacity;

Wall thickness: SCH10S (7.92mm) wall thickness standard, which effectively reduces the overall weight of the flange and lowers the installation load of the pipeline system while ensuring structural strength;

Standard: Strictly follow the ASME B16.47 Series B standard, which is specifically designed for large-diameter steel pipe flanges. It has strict regulations on flange size tolerances, sealing performance, welding requirements, etc., ensuring the reliable performance of the product in high-pressure, high-temperature, and strong corrosive environments.

After receiving this batch of ASTM A182 F316 wn flange, the customer conducted acceptance inspection on the products. After testing, the dimensional accuracy, surface quality, and material properties of all flanges fully meet the order requirements, especially the flatness of the sealing surface and the processing quality of the welding groove, which far exceed customer expectations.

ASTM A182: A standard of the American Society for Testing and Materials, which specifically covers the requirements for high-performance materials used in the manufacture of flanges, fittings, and other pressure components.

F316L: is the material grade code in ASTM A182 standard. 'F' represents forged. 316L is a low-carbon austenitic stainless steel material.

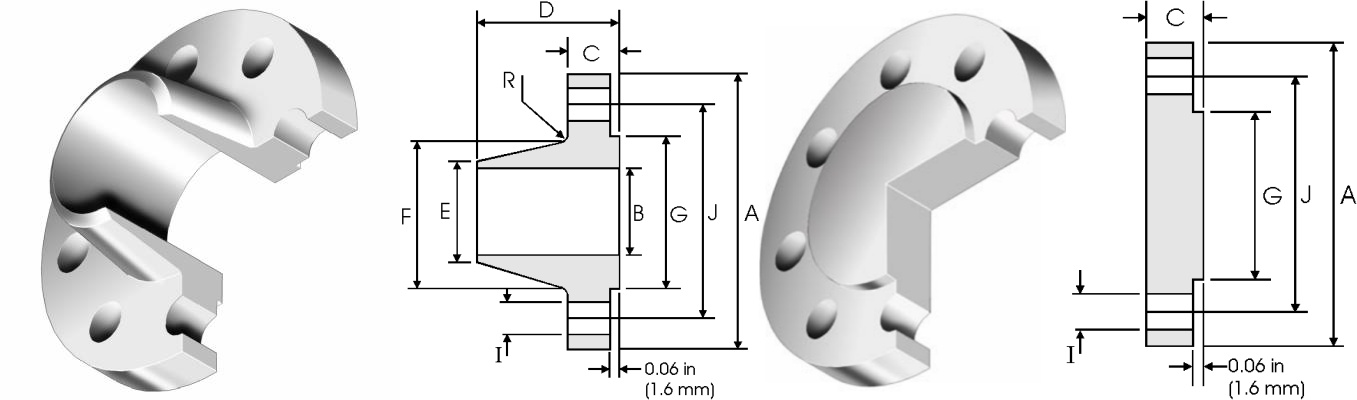

WN flange: It is the most common type of flange with a tapered neck (Hub) that needs to be welded to the pipeline through groove welding. This connection method has high strength and is suitable for industrial environments with high pressure, high temperature, or large temperature fluctuations.

This is the core value of the flange, which determines its application scenarios. F316L is an upgraded version of ordinary 304/304L stainless steel. The main features of ASTM A182 F316L weld neck flange are:

Excellent corrosion resistance

Adding molybdenum (Mo): This is the most crucial difference between 316/316L and 304/304L. The addition of molybdenum significantly improves the resistance to chloride pitting and crevice corrosion. This makes it perform much better than 304 stainless steel in marine environments and chemical processes, especially in media containing halides such as chloride ions.

Low carbon content (L)

L "represents low carbon (Carbon ≤ 0.03%). Low carbon content reduces the risk of chromium carbide precipitation during welding or heating in the sensitive temperature range (450 ° C-850 °C), thereby avoiding intergranular corrosion. This makes it particularly suitable for large components that require welding, without the need for annealing treatment after welding.

Chemical composition

| CHEMICAL | LIMITS | C | Mn | P | S | Si | Ni | Cr | Mo | N |

| ASTM A182 F316L | MIN | 10.00 | 16.00 | 2.00 | ||||||

| MAX | 0.03 | 2.00 | 0.045 | 0.030 | 1.00 | 15.00 | 18.00 | 3.00 | 0.01 |

Good high-temperature performance

It has good oxidation resistance and strength at high temperatures, but is usually used in corrosive environments at medium and low temperatures, and its high-temperature performance is not as good as some alloy steels.

Mechanical Properties

| MATERIAL | T.S (MPA) | Y.S (MPA) | EL % | R/A % |

| ASTM A182 F316L | 485 min | 170 min | 30 min | 50 min |

The ASME B16.47 standard covers large-diameter forged flanges (NPS 26 to NPS 60). This standard is divided into two series: Series A and Series B. Series B flange is derived from API 605 standard, and its size and load-bearing capacity are different from Series A derived from MSS SP-44.

Simply put, Series B flanges are lighter, thinner, and have smaller bolt ring diameters than Series A flanges of the same size and pressure rating. This means that they usually have lower costs, but their load-bearing capacity (especially bending resistance) is relatively weak. When choosing, it is necessary to follow the requirements of pipeline design specifications.

Size: NPS 26 "to NPS 60".

Pressure ratings: typically include 75, 150, 300, 400, 600, and 900 pound classes. The most commonly used are Class 150, 300, and 600.

Flange type: The standard includes not only weld neck flanges, but also blind flanges. But what you are asking about is weld neck flanges, which is the most common type among them.

Butt welding connection: The flange has a long conical neck (Hub) and is connected to the pipeline through groove welding. This connection method has extremely high strength and can withstand extremely high pressure, temperature, and mechanical loads, especially suitable for harsh working conditions and situations where fatigue may occur (such as temperature cycling).

Sealing surface type:

Convex surface (RF): The most common, with a ring-shaped convex sealing surface.

Ring Connection Surface (RTJ): Used for higher pressure conditions, the flange surface has grooves for accommodating metal ring gaskets (such as elliptical or octagonal rings), with superior sealing performance.

| Nominal Pipe Size | A | C | D | E | F | G | H | I | J | R | |

| mm | mm | mm | mm | mm | mm | mm | Holes | mm | mm | mm | |

| 26 | 785.88 | 41.15 | 44.45 | 88.90 | 661.92 | 684.28 | 711.20 | 36 | 22.35 | 744.47 | 9.65 |

| 28 | 836.68 | 44.45 | 47.75 | 95.25 | 712.72 | 735.08 | 762.00 | 40 | 22.35 | 795.27 | 9.65 |

| 30 | 887.48 | 44.45 | 50.80 | 100.08 | 763.52 | 787.40 | 812.80 | 44 | 22.35 | 846.07 | 9.65 |

| 32 | 941.32 | 45.97 | 53.85 | 107.95 | 814.32 | 839.72 | 863.60 | 48 | 22.35 | 900.18 | 9.65 |

| 34 | 1004.8 | 49.28 | 57.15 | 110.24 | 865.12 | 892.05 | 920.75 | 40 | 25.40 | 957.33 | 9.65 |

| 36 | 1057.1 | 52.32 | 58.67 | 117.35 | 915.92 | 944.63 | 971.55 | 44 | 25.40 | 1009.7 | 9.65 |

| 38 | 1124.0 | 53.85 | 63.50 | 123.95 | 968.25 | 996.95 | 1022.4 | 40 | 28.45 | 1069.8 | 9.65 |

| 40 | 1174.8 | 55.63 | 66.55 | 128.52 | 1019.0 | 1049.3 | 1079.5 | 44 | 28.45 | 1120.6 | 9.65 |

| 42 | 1225.6 | 58.67 | 68.33 | 133.35 | 1069.8 | 1101.9 | 1130.3 | 48 | 28.45 | 1171.4 | 11.18 |

| 44 | 1276.4 | 60.45 | 71.37 | 136.65 | 1120.6 | 1152.7 | 1181.1 | 52 | 28.45 | 1222.2 | 11.18 |

| 46 | 1341.4 | 61.98 | 74.68 | 144.53 | 1171.4 | 1205.0 | 1234.9 | 40 | 31.75 | 1284.2 | 11.18 |

| 48 | 1392.2 | 65.02 | 77.72 | 149.35 | 1222.2 | 1257.3 | 1289.1 | 44 | 31.75 | 1335.0 | 11.18 |

Due to its excellent corrosion resistance, ASTM A182 F316L wn flanges are widely used in the following industries:

Chemical and petrochemical processing: handling acids, bases, solvents, and other corrosive chemicals.

Oil and natural gas: used in pipeline systems with corrosive media such as H ₂ S, CO ₂, chloride ions.

Pharmaceutical industry: Process pipelines with extremely high requirements for material purity and corrosion resistance.

The food and beverage industry requires equipment that is easy to clean and corrosion-resistant.

Paper industry: Processing corrosive chemical pulp liquids.