Views: 5 Author: Site Editor Publish Time: 2025-10-30 Origin: Site

As a professional flange supplier, our long-standing customer trust reflects our product quality and service strength. In late September, we successfully secured an order from a long-term Singaporean client for JIS B2220 flanges. Built on years of reliable cooperation and our expertise in Japanese standard flanges, the entire process—from order confirmation to production and delivery—was executed smoothly and efficiently.

All products in this order are JIS B2220 carbon steel plate flanges (SOP), which offer significant advantages over welding neck (WN) and socket welding (SW) flanges. With a simplified manufacturing process that eliminates neck forging and threading, these flanges reduce production costs while maintaining standard compliance, offering strong price competitiveness. Additionally, plate flanges are ideal for low to medium-pressure pipelines, meeting the requirements of general industrial applications while ensuring sealing performance and stability without over-specification.

Customer trust is not only the foundation of our cooperation but also the motivation for strict quality control. Before shipment, our quality inspection team conducts comprehensive checks in accordance with standard requirements—from dimensional parameters to material performance , and even details like sealing surface flatness and smoothness. Every indicator is verified to meet standards.

Considering the cross-border shipment to Singapore, we used custom wooden cases to protect the flanges from impact and moisture during transit, ensuring product safety throughout the logistics process.

ITEM | DESCRIPTION | QTY | UNIT |

45 | FLANGE M/S FF JIS B2220 3/4" X 5K .C/W MILL CERT | 42 | PC |

46 | FLANGE M/S FF JIS B2220 1" X 5K .C/W MILL CERT | 36 | PC |

47 | FLANGE M/S FF JIS B2220 1 1/4" X 5K .C/W MILL CERT | 180 | PC |

48 | FLANGE M/S FF JIS B2220 1 1/2" X 5K .C/W MILL CERT | 214 | PC |

49 | FLANGE M/S FF JIS B2220 2" X 5K .C/W MILL CERT | 608 | PC |

50 | FLANGE M/S FF JIS B2220 2 1/2" X 5K .C/W MILL CERT | 168 | PC |

51 | FLANGE M/S FF JIS B2220 3" X 5K .C/W MILL CERT | 410 | PC |

52 | FLANGE M/S FF JIS B2220 4" X 5K .C/W MILL CERT | 118 | PC |

53 | FLANGE M/S FF JIS B2220 5" X 5K .C/W MILL CERT | 68 | PC |

54 | FLANGE M/S FF JIS B2220 6" X 5K .C/W MILL CERT | 52 | PC |

55 | FLANGE M/S FF JIS B2220 8" X 5K .C/W MILL CERT | 90 | PC |

56 | FLANGE M/S FF JIS B2220 10" X 5K .C/W MILL CERT | 4 | PC |

57 | FLANGE M/S FF JIS B2220 12" X 5K .C/W MILL CERT | 64 | PC |

TOTAL | 2054 | PCS | |

In industrial pipeline systems, flanges serve as critical connecting components, and their quality and performance directly affect the safety and stability of the entire system. JIS B2220 Japanese standard flanges are widely used in the global industrial field due to their strict standard specifications, diverse selection of types, and reliable performance. This article will comprehensively interpret JIS B2220 standard flanges from the aspects of standard introduction, types, sealing surfaces, materials, dimensional parameters, weight, and comparison with ASME standards.

JIS B2220 is a key Japanese Industrial Standard for steel pipe flanges, specifying their structure, dimensions, technical requirements, inspection methods, and marking. It applies to industrial piping systems with nominal pressures from 5K to 63K and nominal diameters from 10A to 1500A. The standard emphasizes detailed control to ensure flanges maintain reliable sealing and structural strength under high-temperature and high-pressure conditions, thereby supporting the safety and stability of industrial operations.

JIS B2220 references multiple related Japanese standards, including:

JIS G3101 (Rolled Steel for General Structure) for base material properties

JIS G3201 (Carbon Steel Forgings for General Use) for matching pipeline materials

JIS B0203 (Pipe Threads) for threaded connection specifications

JIS Z2241 (Metallic Materials – Tensile Testing Method) for material performance verification

These references ensure that every JIS B2220 flange complies with stringent quality requirements.

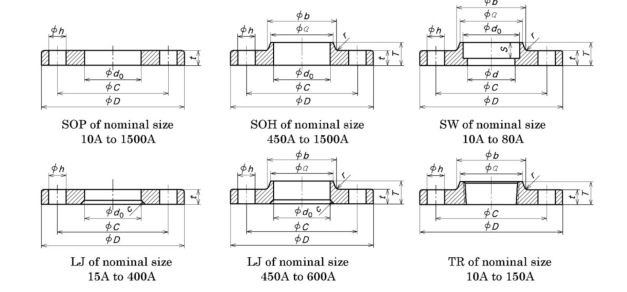

JIS B2220 flanges can be divided into various types based on connection methods and structural characteristics to meet the needs of different industrial scenarios:

| Classification of Flange | Designation | Figure | |

| Welding Flange | Slipon welding flange (plate flange) | SOP |   |

| Slip-on welding flange (hubbed flange) | SOH |   | |

| Socket welding flange | SW |   | |

| Welding neck flange | WN |   | |

| Lap joint flange | LJ |   | |

| Threaded flange | TR |   | |

| Integral flange | IT |   | |

| Blank flange | BL |   | |

Slip on welding flange (plate flange)(SOP): With a simple structure and low cost, it is connected to the pipeline through fillet welds and is suitable for situations with low pressure and low sealing requirements.

Slip-on welding flange (hubbed flange) (SOH): With a short neck, it enhances the rigidity and load-bearing capacity of the flange, making it easier to ensure coaxiality between the flange neck and the pipeline during welding.

Socket welding flange (SW): Suitable for pipelines with smaller nominal diameters, the pipeline is inserted into the flange socket and welded, with good sealing performance. It is commonly used in instrument pipelines, small-diameter high-pressure pipelines, etc.

Welding neck flange (WN): With a long neck, it is connected to the pipeline by butt welding, with high welding quality and the ability to withstand high pressure and temperature. It is widely used in high-pressure and high-temperature industrial pipelines.

Lap joint flange (LJ): The flange ring is movable and can be used in conjunction with flanged or welded rings for easy installation and alignment.

Threaded flange (TH): Connected to pipelines through threads without welding, easy to install, suitable for situations where welding is not allowed or difficult to weld, such as flammable and explosive medium pipelines, stainless steel pipelines, etc., but not suitable for high-pressure working conditions.

Integrated flange (IT): A flange cast/forged as a whole with equipment, valves, or fittings.

Blink flange (BL): used to close the end of a pipeline or reserve an opening, without a central hole.

The gasket face is the key part for flanges to achieve sealing. The sealing surface of JIS B2220 standard flanges mainly includes the following types:

| Classification of Gasket Face | Designation | Figure | ||

| Full face | FF |   | ||

| Raised face | RF |   | ||

| Male-female face | Male seat | MF | MF-M |   |

| Female seat | MF-F |   | ||

| Tongue and groove | Tongue seat | TG | TG-T |   |

| Groove seat | TG-G |   | ||

Full Face (FF):

Features a flat, continuous sealing surface. Simple design and easy to machine, but offers relatively lower sealing performance.

Raised Face (RF):

The sealing surface is raised above the flange face, providing moderate gasket contact area and improved sealing performance compared to FF. This is the most widely used type。

Male-Female Face (MFM):

Consists of a matching male and female pair. The gasket fits inside the female recess, preventing extrusion under pressure.

Tongue and Groove (TG):

Uses a tongue-and-groove pairing to securely locate the gasket within the groove. Offers high sealing reliability and resistance to high pressure and temperature.

Material selection for JIS B2220 flanges depends on operating conditions such as pressure, temperature, and medium characteristics. Common materials include:

Carbon Steel (e.g., SS400, S35C)

Offers good strength and toughness at low cost. It is one of the most widely used flange materials in general industry.

Alloy Steel (e.g., SFVAF1, SFVAF11A)

Provides high-temperature strength and moderate corrosion resistance.

Stainless Steel (e.g., SUS F304, SUS F316, SUS F316L)

Delivers excellent corrosion resistance against acidic and alkaline media. SUS316L offers enhanced intergranular corrosion resistance due to its molybdenum content.

| Material | Rolled Steel | Steel Forgings | Steel Castings | Material Group No. | |||

| Standard | Symbol of Material | Standard | Symbol of Materia | Standard | Symbol of Materia | ||

| Carbon Steel | JIS G 3101 JISG 4051 | SS 400 a) S20C b) | JIS G 3201 JIS G 3202 JIS G 4051 | SF 390A a) SFVC1 S20C b) | JIS G 5101 JIS G5151 | SC 410 SCPH1 | 001 |

| JIS G4051 | S25C b) | JIS G 3201 JIS G 4051 | SF 440A a) S25C b) | JIS G 5101 | SC 480 | 002 | |

| 一 | 一 | JIS G3202 | SFVC 2A | JIS G5151 | SCPH 2 | 003a | |

| Low Alloy Steel | 一 | 一 | JIS G 3203 | SFVAF1 | JIS G 5151 | SCPH 11 | 013a |

| 一 | 一 | JIS G 3203 | SFVAF11A | JIS G 5151 | SCPH21 | 015a | |

| Stainless Steel | JIS G 4304 JIS G 4305 | SUS 304 SUS 304 | JIS G 3214 | SUS F304 | JIS G5121 | SCS 13A | 021a |

| 一 | 一 | 一 | 一 | JIS G 5121 | SCS 19A | 021b | |

| JIS G 4304 JIS G 4305 | SUS 316 SUS 316 | JIS G 3214 | SUS F316 | JISG 5121 | SCS 14A | 022a | |

| 一 | 一 | 一 | 一 | JIS G5121 | SCS 16A | 022b | |

| JIS G 4304 JIS G 4305 | SUS 304L SUS 304L | JISG 3214 | SUS F304L | 一 | 一 | 023a | |

| JIS G 4304 JIS G 4305 | SUS 316L SUS 316L | JIS G 3214 | SUS F316L | 一 | 一 | 023b | |

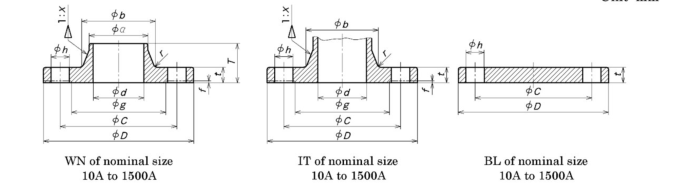

The size parameter specifications for JIS B2220 standard flanges mainly include nominal diameter (DN, unit: A), nominal pressure (PN, unit: K), flange outer diameter, bolt hole center circle diameter, bolt hole quantity and diameter, flange thickness, neck size (for necked flanges), etc. The size parameters of flanges with different nominal pressures and nominal diameters are clearly defined to ensure their compatibility with components such as pipelines and valves.

| Nominal size A | Joined dimension | Inside diameter | Depth of socket S | Nominal designation of thread | Raised face | ||||||||

| Outside diameter of flange D | Diameter of bolt hole centre circle C | Diameter of bolt hole h | Number of bolts | Nominal tion of thread of bolt | d 0 | d 0 | d a) | (Informative) d | Diameter g | Height f | |||

| SOP,SOH,SW,LJ,TR,WN,IT,BL | SOP SOH, SW | LJ | SW, WN | IT | SW | TR | WN,IT | ||||||

| 10 15 20 | 75 80 85 | 55 60 65 | 12 12 12 | 4 4 4 | M10 M10 M10 | 17.8 22.2 27.7 | 一 23.4 28.9 | 12.7 16.1 21.6 | 10 15 20 | 10 10 13 | Rc 3/8 Rc 1-1/2 Rc 3/4 | 39 44 49 |  1 11 1 |

| 25 32 40 | 95 115 120 | 75 90 95 | 12 15 15 | 4 4 4 | M10 M12 M12 | 34.5 43.2 49.1 | 35.6 44.3 50.4 | 27.6 35.7 41.6 | 25 32 40 | 13 13 13 | Rc 1 Rc 11/4 Rc 11/2 | 59 70 75 | 1 2 2 |

| 50 65 80 | 130 155 180 | 105 130 145 | 15 15 19 | 4 4 4 | M12 M12 M16 | 61.1 77.1 90.0 | 62.7 78.7 91.6 | 52.9 67.9 80.7 | 50 65 80 | 16 16 16 | Rc 2 Rc 21/2 Rc 3 | 85 110 121 | 2 2 2 |

| 90 100 125 | 190 200 235 | 155 165 200 | 19 19 19 | 4 8 8 | M16 M16 M16 | 102.6 115.4 141.2 | 104.1 116.9 143.0 | 93.2 105.3 130.8 | 90 100 125 | 一 一 一 | 一 Rc 4 Rc 5 | 131 141 176 | 2 2 2 |

| 150 175 200 | 265 300 320 | 230 260 280 | 19 23 23 | 8 8 8 | M16 M20 M20 | 166.6 192.1 218.0 | 168.4 一 219.5 | 155.2 180.1 204.7 | 150 175 200 | 一 一 一 | Rc 6 一 一 | 206 232 252 | 2 2 2 |

| 225 250 300 | 345 385 430 | 305 345 390 | 23 23 23 | 12 12 12 | M20 M20 M20 | 243.7 269.5 321.0 | 一 271.7 322.8 | 229.4 254.2 304.7 | 225 250 300 | 一 一 一 | 一 一 一 | 277 317 360 | 2 2 3 |

| 350 400 450 | 480 540 605 | 435 495 555 | 25 25 25 | 12 16 16 | M22 M22 M22 | 358.1 409 460 | 360.2 411.2 462.3 | 339.8 390.6 441.4 | 340 400 450 | 一 一 一 | 一 一 一 | 403 463 523 | 3 3 3 |

| 500 550 600 | 655 720 770 | 605 665 715 | 25 27 27 | 20 20 20 | M22 M24 M24 | 511 562 613 | 514.4 565.2 616.0 | 492.2 543.0 593.8 | 500 550 600 | 一 一 一 | 一 一 一 | 573 630 680 | 3 3 3 |

| 650 700 750 | 825 875 945 | 770 820 880 | 27 27 33 | 24 24 24 | M24 M24 M30 | 664 715 766 | 一 一 一 | 644.6 695.4 746.2 | 650 700 750 | 一 一 一 | 一 一 一 | 735 785 840 | 3 3 3 |

| 800 850 900 | 995 1045 1095 | 930 980 1030 | 33 33 33 | 24 24 24 | M30 M30 M30 | 817 868 919 | 一 一 一 | 797.0 847.8 898.6 | 800 850 900 | 一 一 一 | 一 一 一 | 890 940 990 | 3 3 3 |

| 1000 1100 1200 | 1195 1305 1420 | 1130 1240 1350 | 33 33 33 | 28 28 32 | M30 M30 M30 | 1021 1122 1224 | 一 一 一 | 1000.2 1098.6 1200.2 | 1000 1100 1200 | 一 一 一 | 一 一 一 | 1090 1200 1305 | 3 3 3 |

| 1350 1500 | 1575 1730 | 1505 1660 | 33 33 | 32 36 | M30 M30 | 1376 1529 | 一 一 | 1346.2 1498.6 | 1350 1500 | 一 一 | 一 一 | 1460 1615 | 3 3 |

| Nominal size A | Thickness of flange | Diameter of hub Small diameter side | Diameter of hub Large diameter side | Taper of hub | Total length of flange | Chamfering e) c | Radius of fillet | Alternative dimensions of WN① | |||||||

| Thickness of flange t | Taper of hub x | ||||||||||||||

| t | t | a | a | b | b b) | x | Min. x | T | T | r | r b) | ||||

| Except for BL | BL | SOH, SW, LJ, TR | WN | SOH, SW, LJ, TR | WN, IT | WN | IT | SOH, SW, LJ,TR | WN | LJ | SOH,SW, LJ,TR | WN, IT | WN | ||

| 10 15 20 | 9 9 10 | 9 9 10 | 23 27 33 | 17.3 21.7 27.2 | 26 30 36 | 26 31 38 | 1.25 1.25 1.25 | 1.25 1.25 1.25 | 13 13 15 | 24 25 28 | 33 | 44 | 4 4 4 | 一 一 一 | 一 一 一 |

| 25 32 40 | 10 12 12 | 10 12 12 | 41 50 56 | 34.0 42.7 48.6 | 44 53 60 | 46 55 62 | 1.25 1.25 1.25 | 1.25 1.25 1.25 | 17 19 20 | 30 33 34 | 3 4 4 | 4 4 4 | 4 4 4 | 一 一 一 | 一 一 一 |

| 50 65 80 | 14 14 14 | 14 14 14 | 69 86 99 | 60.5 76.3 89.1 | 73 91 105 | 73 91 105 | 1.25 1.25 1.25 | 1.25 1.25 1.25 | 24 27 30 | 36 39 41 | 4 5 5 | 4 4 4 | 4 4 44 | 一 一 一 | 一 一 一 |

| 90 100 125 | 14 16 16 | 14 16 16 | 一 127 154 | 101.6 114.3 139.8 | 一 130 161 | 117 128 156 | 1.25 1.25 1.25 | 1.25 1.25 1.25 | 一 36 40 | 41 41 43 | 5 5 6 | 一 4 4 | 4 4 4 | 一 一 一 | 一 一 一 |

| 150 175 200 | 18 18 20 | 18 18 20 | 182 一 一 | 165.2 190.7 216.3 | 189 一 一 | 184 209 235 | 1.25 1.25 1.25 | 1.25 1.25 1.25 | 40 一 一 | 49 49 53 | 6 一 6 | 4 一 一 | 4 4 4 | 一 一 一 | 一 一 一 |

| 225 250 300 | 20 22 22 | 20 22 22 | 一 一 一 | 241.8 267.4 318.5 | 一 一 一 | 261 290 342 | 1.25 1.25 1.25 | 1.25 1.25 1.25 | 一 一 一 | 54 61 62 | 一 6 9 | 一 一 一 | 4 4 4 | 一 一 一 | 一 一 一 |

| 350 400 450 | 24 24 24 | 24 24 24 | 一 一 495 | 355.6 406.4 457.2 | 一 一 500 | 385 438 491 | 1.25 1.25 1.25 | 1.25 1.25 1.25 | 一 一 40 | 73 76 79 | 9 9 9 | 一 一 5 | 4 4 5 | 一 一 一 | 一 一 一 |

| 500 550 600 | 24 26 26 | 24 26 26 | 546 597 648 | 508.0 558.8 609.6 | 552 603 654 | 541 593 643 | 1.25 1.25 1.25 | 1.25 1.25 1.25 | 40 42 44 | 79 81 81 | 9 9 9 | 5 5 5 | 5 5 5 | 一 一 一 | 一 一 一 |

| 650 700 750 | 26 26 28 | 28 30 32 | 702 751 802 | 660.4 711.2 762.0 | 708 758 810 | 698 748 802 | 1.25 1.5 1.5 | 1.25 1.5 1.5 | 48 48 52 | 85 94 100 | 一 一 一 | 5 5 5 | 5 5 5 | 一 36 38 | 一 1.25 1.25 |

| 800 850 900 | 28 28 30 | 34 36 36 | 854 904 956 | 812.8 863.6 914.4 | 862 912 964 | 852 902 952 | 1.5 1.75 1.75 | 1.5 1.75 1.75 | 52 54 56 | 100 108 108 | 一 一 一 | 5 5 5 | 5 5 5 | 38 38 40 | 1.25 1.5 1.5 |

| 1000 1100 1200 | 32 32 34 | 40 44 48 | 1058 1158 1260 | 1016.0 1117.6 1219.2 | 1066 1170 1272 | 1052 1162 1272 | 2 2 2 | 2 2 2 | 60 71 77 | 116 136 155 | 一 一 一 | 5 7 7 | 5 8 8 | 50 56 62 | 1.5 1.5 1.5 |

| 1350 1500 | 34 36 | 54 58 | 1414 1568 | 1371.6 1524.0 | 1426 1580 | 1427 1582 | 2 2 | 2 2 | 80 86 | 164 172 | 一 一 | 7 7 | 8 10 | 62 66 | 1.5 1.5 |

The weight of the flange is closely related to the material and dimensional parameters. The following are the reference weights (in kg) for some common specifications of JIS B2220 standard flanges (made of carbon steel material):

5K \ 10K Weight List

| Nominal size A | Nominal pressure | |||||||||||||||||

| 5K | 10K | 10K light type | ||||||||||||||||

| SOP | SOH | SW | LJ | TR | W | N H | BL | SOP | SOH | SW | LJ | TR | W | N H | BL | SOP | SOH | |

| 10 15 20 | 0.26 0.30 0.36 | 一 一 一 | 0.27 0.31 0.38 | 一 0.29 0.36 | 0.28 0.31 0.39 | 0.30 0.35 0.44 | 一 一 一 | 0.28 0.32 0.41 | 0.51 0.56 0.72 | 一 一 一 | 0.52 0.58 0.75 | 一 0.56 0.71 | 0.52 0.58 0.75 | 0.55 0.63 0.80 | 一 一 一 | 0.53 0.60 0.79 | 0.42 0.45 0.54 | 一 一 一 |

| 25 32 40 | 0.45 0.77 0.82 | 一 一 一 | 0.48 0.83 0.90 | 0.44 0.76 0.80 | 0.50 0.84 0.91 | 0.56 0.94 1.03 | 一 一 一 | 0.52 0.91 1.00 | 1.12 1.47 1.55 | 一 一 一 | 1.16 1.53 1.65 | 1.11 1.45 1.53 | 1.17 1.54 1.65 | 1.26 1.67 1.78 | 一 一 一 | 1.22 1.66 1.79 | 1.00 1.14 1.20 | 一 一 一 |

| 50 65 80 | 1.06 1.48 1.97 | 一 一 一 | 1.19 1.72 2.34 | 1.03 1.44 1.92 | 1.20 1.74 2.35 | 1.33 1.92 2.53 | 一 一 一 | 1.38 2.00 2.67 | 1.86 2.58 2.58 | 一 一 一 | 1.97 2.77 2.89 | 1.83 2.53 2.52 | 1.99 2.79 2.90 | 2.18 3.07 3.17 | 一 一 一 | 2.23 3.24 3.48 | 1.68 2.05 2.10 | 一 一 一 |

| 90 100 125 | 2.08 2.35 3.20 | 一 一 一 | 一 一 一 | 2.02 2.28 3.08 | 一 2.99 4.29 | 2.70 3.04 4.17 | 一 一 一 | 2.99 3.66 5.16 | 2.73 3.10 4.73 | 一 一 一 | 一 一 一 | 2.66 3.02 4.60 | 一 3.70 5.70 | 3.40 3.89 5.77 | 一 一 一 | 3.90 4.57 7.18 | 2.21 2.86 4.40 | 一 一 一 |

| 150 175 200 | 4.39 5.42 6.24 | 一 一 一 | 一 一 一 | 4.25 一 6.06 | 5.74 一 一 | 5.87 7.16 8.50 | 一 一 一 | 7.47 9.52 12.1 | 6.30 6.75 7.46 | 一 一 一 | 一 一 一 | 6.14 一 7.28 | 7.48 一 一 | 7.86 8.70 10.1 | 一 一 一 | 10.1 11.8 13.9 | 5.30 6.39 7.04 | 一 一 一 |

| 225 250 300 | 6.57 9.39 10.2 | 一 一 一 | 一 一 一 | 一 9.11 9.76 | 一 一 一 | 9.30 13.2 15.1 | 一 一 一 | 13.9 19.2 24.2 | 7.70 11.8 12.6 | 一 12.7 13.8 | 一 一 一 | 一 12.3 13.2 | 一 一 一 | 10.6 16.0 18.1 | 一 一 一 | 15.8 22.6 27.8 | 7.35 11.1 12.0 | 一 一 一 |

| 350 400 450 | 14.0 16.9 21.4 | 一 一 24.9 | 一 一 一 | 13.4 16.2 23.9 | 一 一 一 | 21.6 26.2 32.7 | 一 一 一 | 33.0 41.7 52.7 | 16.3 23.2 29.3 | 18.2 25.8 33.4 | 一 一 一 | 17.4 24.8 32.3 | 一 一 一 | 24.8 34.2 42.7 | 一 一 一 | 36.9 52.1 68.4 | 14.2 一 一 | 一 22.1 一 |

| 500 550 600 | 23.0 30.1 32.5 | 27.0 34.5 37.8 | 一 一 一 | 25.6 33.0 36.2 | 一 一 一 | 35.4 44.4 47.8 | 一 一 一 | 61.6 80.8 92.7 | 33.3 42.9 45.4 | 38.0 49.4 52.6 | 一 一 一 | 36.4 47.7 50.8 | 一 一 一 | 50.3 64.4 69.1 | 60.4 76.7 82.1 | 81.6 112 134 | 一 一 一 | 一 一 一 |

| 650 700 750 | 35.6 38.0 48.4 | 43.2 45.8 57.7 | 一 一 一 | 一 一 一 | 一 一 一 | 54.3 60.6 75.4 | 一 74.0 91.1 | 114 138 171 | 51.8 59.0 72.8 | 60.2 70.2 86.5 | 一 一 一 | 一 一 一 | 一 一 一 | 78.7 94.5 114 | 92.6 129 158 | 161 196 248 | 一 一 一 | 一 一 一 |

| 800 850 900 | 51.2 53.9 60.7 | 61.3 65.3 73.1 | 一 一 一 | 一 一 一 | 一 一 一 | 79.5 87.0 95.2 | 96.3 105 114 | 202 237 260 | 76.0 80.1 88.9 | 92.0 98.7 110 | 一 一 一 | 一 一 一 | 一 一 一 | 120 126 138 | 166 175 190 | 286 330 377 | 一 一 一 | 一 一 一 |

| 1000 1100 1200 | 70.1 81.6 101 | 84.8 105 129 | 一 一 一 | 一 一 一 | 一 一 一 | 111 146 190 | 147 202 265 | 345 454 586 | 109 131 163 | 133 175 215 | 一 一 一 | 一 一 一 | 一 一 一 | 171 222 275 | 236 307 381 | 512 675 854 | 一 一 一 | 一 一 一 |

| 1350 1500 | 116 137 | 151 180 | 一 一 | 一 一 | 一 一 | 240 284 | 324 385 | 814 1060 | 204 248 | 274 340 | 一 一 | 一 一 | 一 一 | 368 459 | 496 624 | 1180 1590 | 一 一 | 一 一 |

10K/20K Weight List

| Nominal size A | Nominal pressure | |||||||||||||

| 16K | 20K | |||||||||||||

| SOH | SW | LJ | TR | WN | BL | SOH | SW | LJ | TR | WN | BL | |||

| A | B | C | ||||||||||||

| 10 | 0.52 | 0.53 | 一 | 0.53 | 0.56 | 0.53 | 0.58 | 0.58 | 一 | 0.60 | 一 | 0.60 | 0.61 | 0.59 |

| 15 | 0.58 | 0.58 | 0.57 | 0.59 | 0.64 | 0.60 | 0.65 | 0.64 | 一 | 0.67 | 0.68 | 0.67 | 0.70 | 0.67 |

| 20 | 0.75 | 0.76 | 0.74 | 0.77 | 0.81 | 0.79 | 0.81 | 0.80 | 一 | 0.84 | 0.84 | 0.84 | 0.88 | 0.86 |

| 25 | 1.16 | 1.18 | 1.15 | 1.19 | 1.27 | 1.22 | 1.27 | 1.26 | 一 | 1.31 | 1.33 | 1.32 | 1.37 | 1.34 |

| 32 | 1.53 | 1.56 | 1.50 | 1.57 | 1.67 | 1.66 | 1.58 | 1.57 | 一 | 1.64 | 1.70 | 1.64 | 1.73 | 1.73 |

| 40 | 1.64 | 1.68 | 1.61 | 1.69 | 1.79 | 1.79 | 1.68 | 1.66 | 一 | 1.74 | 1.80 | 1.74 | 1.85 | 1.87 |

| 50 | 1.83 | 1.88 | 1.79 | 1.90 | 2.05 | 2.09 | 1.89 | 1.86 | 一 | 1.96 | 2.00 | 1.97 | 2.12 | 2.20 |

| 65 | 2.58 | 2.68 | 2.51 | 2.71 | 3.00 | 3.08 | 2.73 | 一 | 2.81 | 2.92 | 2.89 | 2.91 | 3.1 | 3.24 |

| 80 | 3.61 | 3.76 | 3.53 | 3.81 | 4.16 | 4.41 | 3.85 | 一 | 3.95 | 4.13 | 4.04 | 4.08 | 4.30 | 4.63 |

| 90 | 3.89 | 一 | 3.80 | 一 | 4.53 | 4.92 | 4.47 | 一 | 4.59 | 一 | 4.67 | 一 | 5.08 | 5.67 |

| 100 | 4.87 | 一 | 4.76 | 5.18 | 5.76 | 6.29 | 5.03 | 一 | 5.18 | 一 | 5.24 | 5.35 | 5.95 | 6.61 |

| 125 | 7.09 | 一 | 6.92 | 7.76 | 8.39 | 9.21 | 7.94 | 一 | 8.15 | 一 | 8.24 | 8.44 | 9.31 | 10.5 |

| 150 | 9.57 | 一 | 9.35 | 10.2 | 11.5 | 12.7 | 10.4 | 一 | 10.7 | 一 | 10.8 | 11.1 | 12.6 | 14.4 |

| 200 | 12.0 | 一 | 11.8 | 一 | 15.3 | 18.4 | 13.1 | 一 | 13.6 | 一 | 13.6 | 一 | 16.6 | 20.8 |

| 250 | 20.1 | 一 | 19.6 | 一 | 24.8 | 30.4 | 23.1 | 一 | 23.8 | 一 | 23.7 | 一 | 28.3 | 36.2 |

| 300 | 24.3 | 一 | 23.6 | 一 | 31.3 | 40.5 | 27.2 | 一 | 28.1 | 一 | 28.1 | 一 | 34.9 | 47.4 |

| 350 | 34.4 | 一 | 33.5 | 一 | 45.7 | 57.5 | 38.4 | 一 | 39.5 | 一 | 39.7 | 一 | 50.2 | 66.1 |

| 400 | 47.4 | 一 | 46.3 | 一 | 63.6 | 81.7 | 53.9 | 一 | 55.5 | 一 | 55.6 | 一 | 71.7 | 97.0 |

| 450 | 61.8 | 一 | 60.5 | 一 | 82.8 | 107 | 71.0 | 一 | 72.9 | 一 | 73.1 | 一 | 92.8 | 126 |

| 500 | 73.7 | 一 | 71.7 | 一 | 96.3 | 132 | 84.6 | 一 | 86.7 | 一 | 86.5 | 一 | 108 | 155 |

| 550 | 87.9 | 一 | 85.8 | 一 | 116 | 163 | 102 | 一 | 104 | 一 | 104 | 一 | 128 | 190 |

| 600 | 98.4 | 一 | 96.1 | 一 | 130 | 192 | 115 | 一 | 117 | 一 | 117 | 一 | 144 | 223 |

30K/40K/63K Weight List

| Nominal size A | Nominal pressure | ||||||||

| 30K | 40K | 63K | |||||||

| SOH | WN | BL | WN | BL | WN | BL | |||

| A | B | C | |||||||

| 10 15 20 | 1.00 1.24 1.36 | 1.00 1.22 1.34 | 一 一 一 | 一 1.33 1.45 | 1.00 1.25 1.38 | 一 1.47 1.61 | 一 1.40 1.54 | 一 1.89 2.51 | 一 1.78 2.41 |

| 25 32 40 | 1.77 2.17 2.82 | 1.75 2.15 2.79 | 一 一 一 | 1.92 2.39 3.09 | 1.84 2.32 3.00 | 2.14 2.60 3.41 | 2.03 2.54 3.29 | 2.98 3.65 5.54 | 2.83 3.60 5.30 |

| 50 65 80 | 2.89 4.88 5.70 | 2.86 一 一 | 一 4.96 5.80 | 3.24 5.70 6.72 | 3.14 5.50 6.63 | 3.88 6.68 7.61 | 3.74 6.38 7.62 | 6.43 10.9 12.4 | 6.05 9.84 11.5 |

| 90 100 125 | 7.13 8.01 11.6 | 一 一 一 | 7.25 8.16 11.9 | 8.31 9.40 14.0 | 8.55 10.0 15.3 | 9.31 11.8 20.3 | 9.73 12.4 20.2 | 15.4 18.1 30.0 | 14.9 17.7 29.2 |

| 150 200 250 | 17.0 22.2 36.8 | 一 一 一 | 17.3 22.6 37.5 | 20.2 27.2 45.2 | 22.2 32.6 55.2 | 29.2 41.9 66.1 | 30.0 45.7 72.3 | 42.4 61.0 97.3 | 39.2 61.0 95.9 |

| 300 350 400 | 49.1 60.4 82.0 | 一 一 一 | 50.0 61.5 83.7 | 61.0 74.5 103 | 77.9 96.9 136 | 81.2 103 127 | 97.0 123 167 | 128 154 202 | 135 170 233 |

The actual weight may vary slightly due to factors such as material density and processing accuracy, and the actual testing data of the product shall prevail.

JIS (Japanese Industrial Standards) and ASME (American Society of Mechanical Engineers) standards are both globally recognized in the industrial sector. While they share common goals in ensuring flange safety, reliability, and interchangeability—particularly in material performance, sealing principles, and inspection methods—they also exhibit key differences in regional adoption, technical parameters, and design specifications.

Regional & Industrial Application:

JIS standards are widely used in Japan and regions with close trade ties to Japan, commonly found in electronics, automotive, and precision manufacturing industries. ASME standards dominate in North America and are extensively applied in global sectors such as oil, gas, chemicals, and power generation.

Pressure & Temperature Ratings:

JIS B2220 flanges use "K" grades (e.g., 10K, 20K) for nominal pressure, with temperature ratings clearly defined per material. ASME flanges use "Class" units (e.g., 150Class, 300Class) and provide more detailed temperature-pressure rating tables, allowing precise determination of flange pressure limits based on material and temperature.

Dimensional Differences:

Even with similar nominal diameters and pressure ratings, dimensions such as outer diameter, bolt hole circle diameter, number of bolt holes, and hole size may differ. These variations prevent direct interchangeability between JIS and ASME flanges.

Material Standards:

JIS flanges follow Japanese material standards (e.g., JIS G3101, JIS G3106), while ASME flanges comply with ASME material standards (e.g., SA-105, SA-350). Although some materials exhibit similar chemical and mechanical properties, differences remain in grade designations and technical requirements.

JIS B2220 standard flanges offer reliable performance across a wide range of applications—from low-pressure pipelines to high-temperature and high-pressure conditions. Proper selection should consider operating requirements, flange type, sealing surface, material, and dimensional parameters, while also noting incompatibilities with other standards to ensure safe and efficient operation of piping systems.