Views: 10 Author: Site Editor Publish Time: 2025-08-26 Origin: Site

ASTM B564 N06022 steel flanges, made of nickel-chromium-molybdenum-tungsten alloy, are also widely known as Hastelloy C22 steel flanges. With excellent corrosion resistance and high-temperature stability, they are extensively used in special working condition fields.

N06022 steel flanges is a core item in our long-term cooperation with an Italian customer. The customer highly recognizes our professional capabilities and quality control standards, forming a stable cooperation model of regular procurement. As N06022 belongs to special alloy materials, it not only has high raw material costs, but the customer also has extremely strict requirements on product quality and production processes. Therefore, from order receipt to final delivery, we have always promoted full-process management with the goal of "zero defects".

ITEM | DESCRIPTION | QTY | UNIT | REMARK |

1 | FLANGES B565 N06022 ( HASTELLOY C22 ) EN1092/1/01/B PN 16 DN 15 | 20 | EA | GASKET TOP FINISH PHONOGRAPHIC STOCK FINISH |

2 | FLANGES B565 N06022 ( HASTELLOY C22 ) EN1092/1/01/B PN 16 DN 25 | 18 | EA | |

3 | FLANGES B565 N06022 ( HASTELLOY C22 ) EN1092/1/01/B PN 16 DN 40 | 10 | EA | |

4 | FLANGES B565 N06022 ( HASTELLOY C22 ) EN1092/1/01/B PN 16 DN 50 | 19 | EA | |

5 | FLANGES BL. B565 N06022 ( HASTELLOY C22 ) EN1092/1/05 /B PN 16 DN 25 | 10 | EA | |

6 | FLANGES B565 N06022 ( HASTELLOY C22 ) EN1092/1/01/05 /B PN 16 DN 50 | 13 | EA | |

7 | TOTAL | 90 |

After receiving the order, we focused on surface quality and dimensional accuracy, and controlled each production link in accordance with the principle of "quality first".

The customer clearly requires that the N06022 steel flanges surface must meet the standard finish and be free from obvious bumps, scratches, and other defects. To this end, we have formulated special control measures in each production link:

Strictly require "light handling" during production operations to avoid surface damage caused by collision during handling;

Arrange special personnel to monitor the production process. Once obvious surface defects (such as scratches and dents) are found, the repair process is immediately initiated. If the defects cannot be repaired, the blank is directly replaced to prevent non-conforming products from flowing into the next process from the source;

Conduct 100% inspection at the finished product stage to ensure that the surface of each N06022 steel flanges smooth and uniform, without any visually visible defects.

Before shipment, the quality inspection team strictly inspects each key parameter of each Hastelloy C22 steel flanges (including outer diameter, inner diameter, thickness, bolt hole spacing, and sealing surface size) one by one in accordance with the EN1092-1 Standard (European Standard for Flange Dimensions and Tolerances). Professional measuring tools (such as calipers, micrometers, and flange templates) are used to ensure that dimensional deviations fully meet the standard requirements, eliminating installation problems caused by dimensional inconsistencies. At the same time, combined with the parameter requirements for material chemical composition in the ASTM B564 Standard, material testing is conducted using a spectrometer to ensure that the products fully meet international standards and customer needs.

To ensure product safety during long-distance transportation (including land and sea transportation) from domestic factories to Italy, we have designed exclusive packaging solutions for our customers.

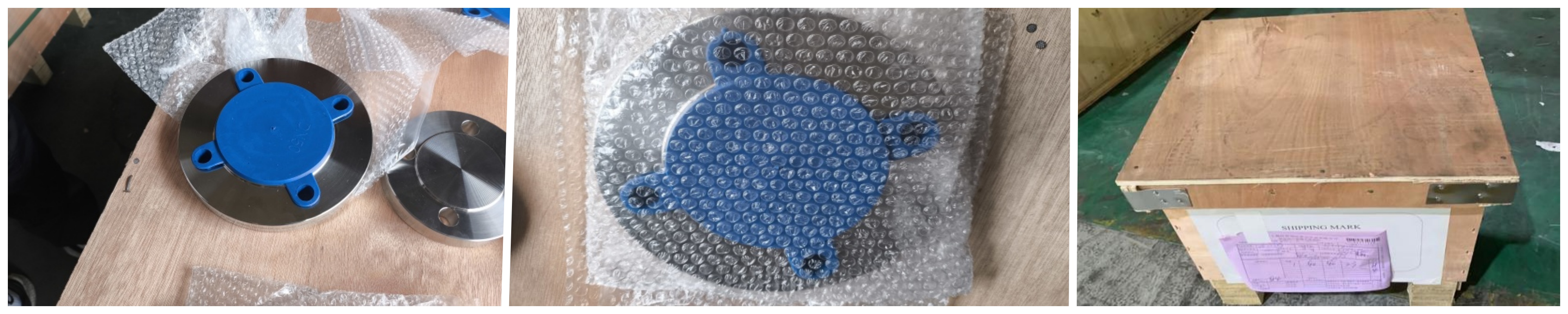

Sealing surface protection: The sealing surface is the core of flange sealing performance and requires special protection. Therefore, we provide dedicated flange covers for each N06022 steel flanges to prevent scratches and deformation of the sealing surface caused by collisions.

Surface protection: The entire flange is wrapped in bubble wrap to reduce direct friction and collision between the flange and other objects during transportation;

Overall fixation and protection: After the individual packaging is completed, the flanges are uniformly packed into customized export wooden boxes. Lay buffer filling on each layer to ensure that there is no space for the flanges to move inside the wooden box and to avoid collisions between the flanges;

Standardized packaging and labeling: Before sealing the wooden box, recheck the quantity and specifications of the products inside the box; After sealing, the wooden box is covered with a packing list for customers to quickly identify and verify upon receipt of the goods.

With strict quality control and comprehensive packaging protection, this batch of N06022 steel flanges has been successfully delivered to Italian customers. After receiving the goods, the customer conducted a 100% inspection according to their internal inspection standards and ultimately achieved a 100% pass rate. The customer not only highly recognized the surface quality and dimensional accuracy of the flange, but also fully affirmed our professional packaging protection and efficient delivery services, further consolidating the long-term cooperation trust between the two parties and laying a solid foundation for continued cooperation in the future.

ASTM B564 is a standard specification for wrought nickel and nickel-alloy flanges, fittings, valves, and parts developed by the American Society for Testing and Materials (ASTM). This standard clearly specifies the material requirements, manufacturing processes, mechanical properties, inspection methods, and dimensional tolerances of wrought nickel-based alloy products.

Based on differences in composition and performance, nickel-based alloys can be divided into multiple series. Common types include:

Hastelloy: Such as Hastelloy C-22 (N06022), C-276 (N10276), B-2 (N10665), etc. Characterized by excellent corrosion resistance, they are suitable for strong corrosion working conditions;

Inconel: Such as Inconel 600 (N06600), 625 (N06625), 718 (N07718), etc. Combining high-temperature strength and corrosion resistance, they are mostly used in high-temperature oxidation and high-temperature & high-pressure environments;

Incoloy: Such as Incoloy 800 (N08800), 825 (N08825), etc. With relatively lower nickel content (about 30%-45%) and higher cost-effectiveness, they are suitable for medium corrosion and medium-high temperature scenarios;

Monel: Such as Monel 400 (N04400), K-500 (N05500), etc. Based on nickel-copper alloy, they are corrosion-resistant to media such as seawater and hydrochloric acid and have high strength;

Other Special Nickel Alloys: Such as nickel-chromium-iron alloys (e.g., Incoloy 800H) and nickel-molybdenum alloys (e.g., Hastelloy B Series), whose properties are optimized for specific working conditions.

Extremely Strong Corrosion Resistance

Excellent High-Temperature Performance

Stable Mechanical Properties

Wide Adaptability

High Cost

High Processing Difficulty

Relatively High Weight

High Difficulty in Recycling and Reuse

UNS N06022 (Hastelloy C22) is a nickel-chromium-molybdenum-tungsten alloy and a high-end grade in the Hastelloy C series, with a precise proportion of chemical components: nickel content serving as the matrix to ensure the basic toughness and corrosion resistance of the alloy, chromium content is about 20.0-22.5% (improving the alloy's corrosion resistance in oxidizing media such as nitric acid and chromic acid), molybdenum content is about 12.5-14.5% (enhancing the alloy's corrosion resistance in reducing media such as hydrochloric acid and sulfuric acid), tungsten content is about 2.5-3.5% (further optimizing the alloy's resistance to localized corrosion such as pitting and crevice corrosion), and it also contains small amounts of iron, cobalt, and other elements to balance mechanical properties.

The core properties of this material include: excellent overall corrosion resistance, capable of withstanding the erosion of both oxidizing and reducing media; outstanding resistance to localized corrosion, which is not prone to pitting or crevice corrosion in high-chloride ion environments (such as seawater and chemical brine); good high-temperature stability, which can maintain mechanical properties for a long time in environments below 650°C and has excellent oxidation resistance; in addition, it also has good weldability and processability, making it easy to manufacture complex structural parts such as flanges and pipe fittings.

Chemical Composition

| CHEMICAL | LIMITS | Ni | Fe | Mn | C | Si | S | Cr | Mo | P | W | Co | V |

| UNS N06022 | MIN | Balance | 2.00 | 20.00 | 12.50 | 2.50 | |||||||

| MAX | 6.00 | 0.50 | 0.02 | 0.08 | 0.02 | 22.50 | 14.50 | 0.02 | 3.50 | 2.50 | 0.35 |

Mechanical Properties

| MATERIAL | T.S (MPA) | Y.S (MPA) | EL % |

| UNS N06022 | 690 min | 276 min | 30 min |

With excellent comprehensive performance, N06022 steel flanges are widely used in industries with high requirements for material performance, mainly including:

Chemical and Petrochemical Industry

Oil and Gas Industry

Power Industry

Marine Engineering Industry

Pharmaceutical and Food Industry

Aerospace Industry