Views: 18 Author: Site Editor Publish Time: 2025-10-21 Origin: Site

In industrial piping systems, elbows, as core components for changing the direction of fluid flow, have their performance and compliance with standards directly impacting the safety and efficiency of the entire system. The ASME B16.9 90 degree butt weld elbow, a classic product conforming to the standards of the American Society of Mechanical Engineers (ASME), is widely used in industries such as petroleum, chemical, and energy due to its precise dimensional control and stable structural performance. It has become an indispensable connecting component in industrial piping engineering.

Long Radius Elbow (LR)

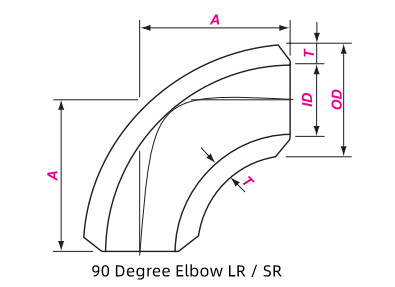

The bend radius (R) is equal to 1.5 times the pipe's nominal diameter (DN), i.e., R=1.5DN. Its advantages include lower flow resistance for the medium, reduced pressure loss, and more uniform stress distribution. It can adapt to higher working temperatures and pressures, making it the most commonly used type in industrial piping systems, suitable for most conventional medium transport scenarios like petroleum pipelines and chemical process piping.

Short Radius Elbow (SR)

The bend radius (R) is equal to 1 times the pipe's nominal diameter (DN), i.e., R=1DN. This type is characterized by a smaller volume and reduced space occupation, making it suitable for installation in space-constrained areas like internal equipment piping or piping layouts within cramped machinery rooms. However, due to the smaller curvature radius, flow resistance is relatively higher, and pressure loss is slightly increased. They are generally not suitable for conveying high-pressure, high-velocity media, or media sensitive to flow resistance.

Seamless Elbow

Formed from high-quality pipe material through processes like hot pushing or extrusion, the entire fitting has no longitudinal weld seam. It features high strength and good pressure resistance. It is suitable for high-pressure, high-temperature piping systems and those requiring high media purity, such as petroleum refining units and natural gas transmission pipelines. Under high-pressure conditions, the seamless structure effectively avoids potential stress concentration issues at weld seams, ensuring long-term stable operation of the piping system.

Welded Elbow

Formed by hot pressing steel plate followed by welding, or made using welded pipe as raw material through pushing. There is a longitudinal weld seam along the fitting's axis. Compared to seamless elbows, welded elbows have lower production costs and higher production efficiency. They are suitable for medium- and low-pressure piping systems, such as civil building water supply and drainage, and general industrial circulating water pipelines. Through strict welding process control and non-destructive testing, welded elbows can also meet the usage requirements for most conventional operating conditions, offering significant advantages in cost-sensitive projects.

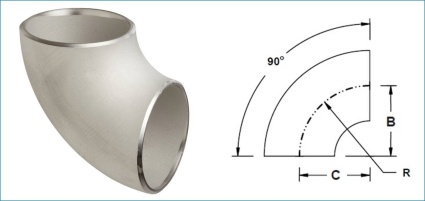

Nominal Diameter (DN): The nominal diameter range for ASME B16.9 90-degree welding elbows typically spans from DN15 (1/2 inch) to DN2000 (80 inches), adapting to piping systems of different specifications.

Bend Radius (R): For Long Radius elbows, R=1.5DN; for Short Radius elbows, R=1DN.

End Wall Thickness (t): The wall thickness must conform to the corresponding pipe wall thickness schedule (e.g., SCH40, SCH80, SCH160, etc.) specified in the ASME B16.9 standard. For example, the wall thickness for a DN100 SCH40 elbow is 6.02mm, and for a SCH80 elbow, it is 8.56mm, ensuring matching wall thickness with pipes of the same schedule and guaranteeing weld strength.

| Nominal size | Outside Diameter at Bevel | Center to End | ||

| 90° Elbows | ||||

| DN | NPS | OD | A | |

| LR | SR | |||

| 15 | 1/2 | 21.3 | 38 | - |

| 20 | 3/4 | 26.7 | 38 | - |

| 25 | 1 | 33.4 | 38 | 25 |

| 32 | 1 1/4 | 42.2 | 48 | 32 |

| 40 | 1 1/2 | 48.3 | 57 | 38 |

| 50 | 2 | 60.3 | 76 | 51 |

| 65 | 2 1/2 | 73.0 | 95 | 64 |

| 80 | 3 | 88.9 | 114 | 76 |

| 90 | 3 1/2 | 101.6 | 133 | 89 |

| 100 | 4 | 114.3 | 152 | 102 |

| 125 | 5 | 141.3 | 190 | 127 |

| 150 | 6 | 168.3 | 229 | 152 |

| 200 | 8 | 219.1 | 305 | 203 |

| 250 | 10 | 273.0 | 381 | 254 |

| 300 | 12 | 323.8 | 457 | 305 |

| 350 | 14 | 355.6 | 533 | 356 |

| 400 | 16 | 406.4 | 610 | 406 |

| 450 | 18 | 457.0 | 686 | 457 |

| 500 | 20 | 508.0 | 762 | 508 |

| 550 | 22 | 559.0 | 838 | 559 |

| 600 | 24 | 610.0 | 914 | 610 |

| 650 | 26 | 660.0 | 991 | 660 |

| 700 | 28 | 711.0 | 1067 | 711 |

| 750 | 30 | 762.0 | 1143 | 762 |

| 800 | 32 | 813.0 | 1219 | 813 |

| 850 | 34 | 864.0 | 1295 | 864 |

| 900 | 36 | 914.0 | 1372 | 914 |

| 950 | 38 | 965.0 | 1448 | 965 |

| 1000 | 40 | 1016.0 | 1524 | 1016 |

| 1050 | 42 | 1067.0 | 1600 | 1067 |

| 1100 | 44 | 1118.0 | 1676 | 1118 |

| 1150 | 46 | 1168.0 | 1753 | 1168 |

| 1200 | 48 | 1219.0 | 1829 | 1219 |

The weight of an elbow is directly related to its nominal diameter, wall thickness schedule, and bend radius. The theoretical weight calculation formula for a 90-degree butt weld elbow is: (D - t) × t × 0.0387 × R / 1000 (Where t = wall thickness in mm; D = outer diameter in mm; R = bend radius in mm).

Reference weights for products of different specifications are also provided, for example:

DN50 SCH40 Long Radius elbow (OD 60.3mm, wall thickness 3.91mm), theoretical weight approximately 0.71kg.

DN100 SCH80 Long Radius elbow (OD 114.3mm, wall thickness 8.56mm), theoretical weight approximately 5.86kg.

DN80 SCH40 Short Radius elbow (OD 88.9mm, wall thickness 5.49mm), theoretical weight approximately 2.2kg.

Actual weight may slightly deviate due to material density (e.g., carbon steel vs. stainless steel), minor variations in manufacturing processes, but must be controlled within the tolerance range allowed by the standard.

Petroleum and Chemical Industry

Energy and Power Sector

Municipal Engineering

Machinery Manufacturing

Food and Pharmaceutical Industry

With its standardized structure, diverse type selection, and wide compatibility, the ASME B16.9 90-degree welding elbow serves as a core component for achieving right-angle direction changes in industrial piping systems, providing reliable assurance for the safe operation of pipelines across different sectors.