Views: 15 Author: Site Editor Publish Time: 2025-10-29 Origin: Site

ASME B16.5 lap joint flange is a simple, disc-shaped fitting with evenly spaced bolt holes. It features a finely finished sealing face and is available in materials like carbon steel, alloy steel, and stainless steel for various piping needs.

Designed for use with a stub end, it is ideal for sections requiring frequent disassembly. Installation is straightforward: no precise alignment is needed, reducing time and effort. Proper gasket selection and installation ensure a reliable seal, while the design accommodates misalignment between equipment and piping, boosting efficiency and ease of construction.

The ASME B16.5 standard specifies pressure classes from 150 to 2500 and sizes from 1/2" to 24" for forged steel flanges. It defines dimensions, materials, pressure-temperature ratings, and sealing surfaces to ensure safety across industries like oil, gas, chemical, and power.

Pressure Classes: 150, 300, 400, 600, 900, 1500, 2500

Size Range: NPS 1/2" to 24"

Scope: Forged steel pipe flanges and fittings

Key Parameters: Dimensions, materials, pressure-temperature ratings, sealing surfaces, and connection methods.

Application: Ensures safety and reliability in pipeline systems for oil, gas, chemical, power, and water treatment.

ASME B16.5 standard covers multiple flange types to suit various applications. These include weld neck, socket weld, threaded, blind, slip-on, and lap joint flanges,each with specific benefits:

Weld Neck Flange(WN): For high-pressure/temperature services; offers high strength.

Socket Weld Flange(SW): Ideal for small-diameter pipes; provides good sealing.

Threaded Flange(TH): Allows welding-free installation.

Blind Flange(BL): Used to seal off pipe ends or openings.

Slip-On Flange(SO): Simple design for low-pressure applications.

Lap Joint Flange(LAPJ): Used with stub ends for easy alignment in systems requiring frequent disassembly.

ASME B16.5 standard mainly specifies the size and tolerance range, pressure and temperature, inspection, testing methods, labeling, packaging, and transportation requirements of flanges to ensure interchangeability, installation accuracy, quality, and safety.

Size | 1/2" - 24" / DN15 - DN600 |

Pressure | Class 150, 300, 600, 900, 1500, 2500lb |

Standard | ASME B16.5 |

Carbon Steel | ASTM A105, 20# ASTM A350 LF2, 16Mn ASTM A694 F42 / 46 / 56 / 60 / 65 |

Alloy Steel | ASTM A182 F11 / 12 / 5 / 9 / 91 / 92 |

Stainless Steel | ASTM A182 F304/304L/304H, 316/316L, 310S, 317,347,904L |

Duplex Stainless Steel | ASTM A182 F51, F53, F55 |

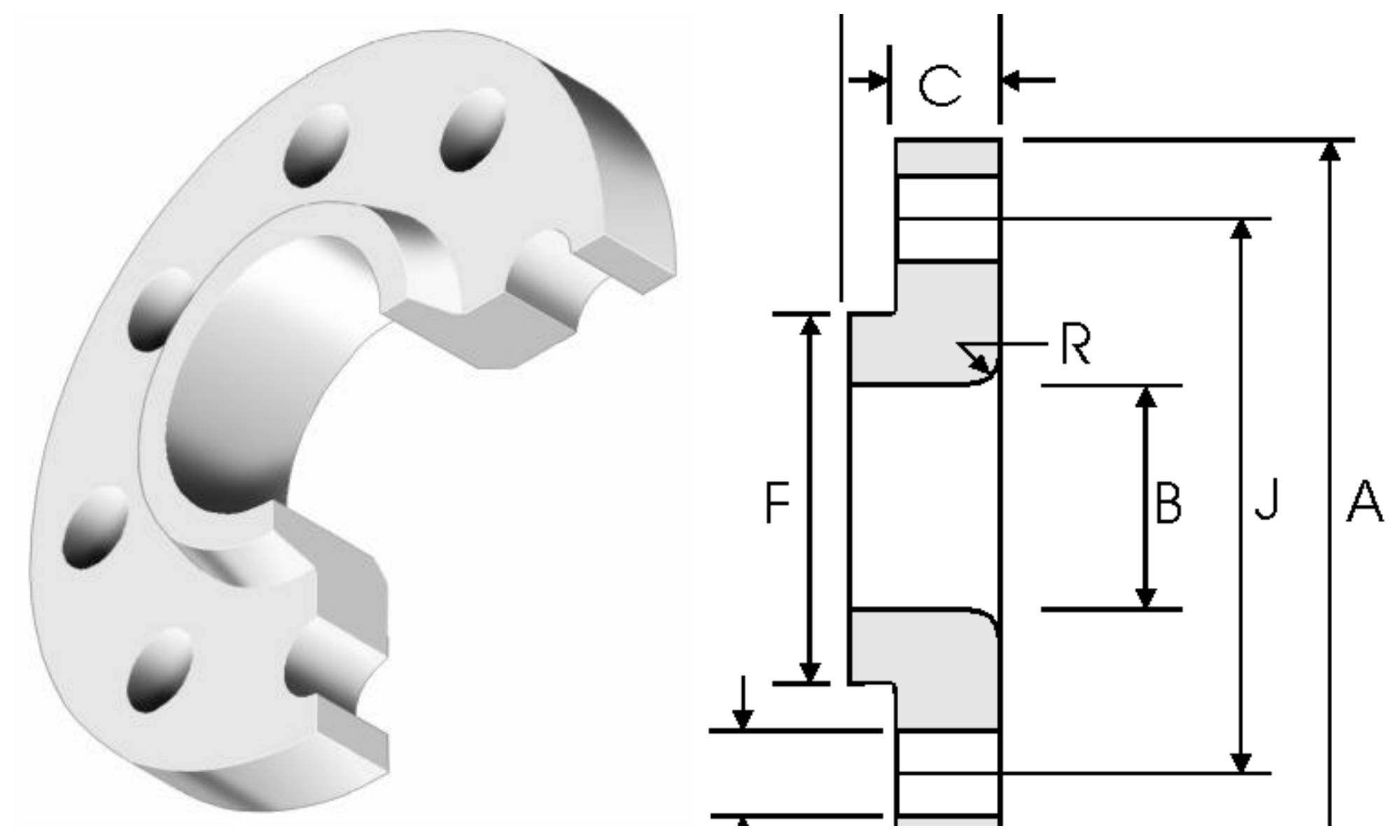

ASME B16.5 lap joint flange is defined by its loose, two-piece design. Key attributes include:

Unique Structure: A freely rotating flange ring that mates with a welded stub end.

Key Advantage: Ease of alignment and compensation for thermal expansion or misalignment.

Maintenance Benefit: The flange ring can be removed simply by unbolting, facilitating easy access for inspection or maintenance without pipe cutting.

NPS |

| B | C | D | R | F | H | I | J | W |

inch | inch | inch | inch | inch | inch | No. of Holes | inch | inch | kg/pc | |

mm | mm | mm | mm | mm | mm | mm | mm | |||

1/2 | 3.500 | 0.900 | 0.440 | 0.620 | 0.120 | 1.190 | 4 | 0.620 | 2.380 | 0.38 |

88.90 | 22.90 | 11.20 | 15.70 | 3.000 | 30.20 | 15.70 | 60.45 | |||

3/4 | 3.880 | 1.110 | 0.500 | 0.620 | 0.120 | 1.500 | 4 | 0.620 | 2.750 | 0.55 |

98.60 | 28.20 | 12.70 | 15.70 | 3.000 | 38.10 | 15.70 | 69.85 | |||

1 | 4.250 | 1.380 | 0.560 | 0.690 | 0.120 | 1.940 | 4 | 0.620 | 3.120 | 0.76 |

108.0 | 35.10 | 14.20 | 17.50 | 3.000 | 49.30 | 15.70 | 79.25 | |||

1¼ | 4.620 | 1.720 | 0.620 | 0.810 | 0.190 | 2.310 | 4 | 0.620 | 3.500 | 1.01 |

117.3 | 43.70 | 15.70 | 20.60 | 4.800 | 58.70 | 15.70 | 88.90 | |||

1½ | 5.000 | 1.970 | 0.690 | 0.880 | 0.250 | 2.560 | 4 | 0.620 | 3.880 | 1.30 |

127.0 | 50.00 | 17.50 | 22.40 | 6.400 | 65.00 | 15.70 | 98.60 | |||

2 | 6.000 | 2.460 | 0.750 | 1.000 | 0.310 | 3.060 | 4 | 0.750 | 4.750 | 2.03 |

152.4 | 62.5 | 19.10 | 25.40 | 7.900 | 77.70 | 19.10 | 120.7 | |||

2½ | 7.000 | 2.970 | 0.880 | 1.120 | 0.310 | 3.560 | 4 | 0.750 | 5.500 | 3.25 |

177.8 | 75.40 | 22.40 | 28.40 | 7.900 | 90.40 | 19.10 | 139.7 | |||

3 | 7.500 | 3.600 | 0.940 | 1.190 | 0.380 | 4.250 | 4 | 0.750 | 6.000 | 3.81 |

190.5 | 91.40 | 23.90 | 30.20 | 9.700 | 108.0 | 19.10 | 152.4 | |||

3½ | 8.500 | 4.100 | 0.940 | 1.250 | 0.380 | 4.810 | 8 | 0.750 | 7.000 | 4.76 |

215.9 | 104.1 | 23.90 | 31.75 | 9.700 | 122.2 | 19.10 | 177.8 | |||

4 | 9.000 | 4.600 | 0.940 | 1.310 | 0.440 | 5.310 | 8 | 0.750 | 7.500 | 5.25 |

228.6 | 116.8 | 23.90 | 33.30 | 11.20 | 134.9 | 19.10 | 190.5 | |||

5 | 10.00 | 5.690 | 0.940 | 1.440 | 0.440 | 6.440 | 8 | 0.880 | 8.500 | 6.02 |

254.0 | 114.5 | 23.90 | 36.60 | 11.20 | 163.6 | 22.40 | 215.9 | |||

6 | 11.00 | 6.750 | 1.000 | 1.560 | 0.500 | 7.560 | 8 | 0.880 | 9500 | 7.40 |

279.4 | 171.5 | 25.40 | 39.60 | 12.70 | 192.0 | 22.40 | 241.3 | |||

8 | 13.50 | 8.750 | 1.120 | 1.750 | 0.500 | 9.690 | 8 | 0.880 | 11.75 | 12.1 |

342.9 | 222.3 | 28.40 | 44.50 | 12.70 | 246.1 | 22.40 | 298.5 | |||

10 | 16.00 | 10.92 | 1.190 | 1.940 | 0.500 | 12.00 | 12 | 1.000 | 14.25 | 16.4 |

406.4 | 277.4 | 30.20 | 49.30 | 12.70 | 304.8 | 25.40 | 362.0 | |||

12 | 19.00 | 12.92 | 1.250 | 2.190 | 0.500 | 14.38 | 12 | 1.000 | 17.00 | 26.1 |

482.6 | 328.2 | 31.75 | 55.60 | 12.70 | 365.3 | 25.4 | 431.8 | |||

14 | 21.00 | 14.18 | 1.380 | 3.120 | 0.500 | 15.75 | 12 | 1.120 | 18.75 | 34.5 |

533.4 | 360.2 | 35.10 | 79.25 | 12.7 | 400.1 | 28.4 | 476.3 | |||

16 | 23.5 | 16.19 | 1.440 | 3.440 | 0.500 | 18.00 | 16 | 1.120 | 21.25 | 44.6 |

296.9 | 411.2 | 36.60 | 87.40 | 12.70 | 457.2 | 284 | 539.8 | |||

18 | 25.00 | 18.20 | 1.560 | 3.810 | 0.500 | 19.88 | 16 | 1.250 | 22.75 | 48.7 |

635.0 | 462.3 | 39.60 | 96.80 | 12.70 | 505.0 | 31.75 | 577.9 | |||

20 | 27.5 | 20.25 | 1.690 | 4.060 | 0.500 | 22.00 | 20 | 1.125 | 25.00 | 61.6 |

698.5 | 514.4 | 42.90 | 103.1 | 12.70 | 558.8 | 31.75 | 635 | |||

24 | 32.00 | 24.25 | 1.880 | 4.380 | 0.500 | 26.12 | 20 | 1.380 | 29.50 | 86.6 |

812.8 | 616.0 | 47.80 | 111.3 | 12.70 | 663.4 | 35.10 | 749.3 |

The above are the detailed parameters of Class 150. Lap joint flanges can be classified according to pressure levels Class 150,Class 300,Class 400,Class 600,Class 900,Class 1500,Class2500, To view other product parameters, please click on the following link:

Stub end is a key component of an ASME B16.5 lap joint flange assembly. It is welded to the pipe, and its lapped end is machined to match the loose flange ring, ensuring a precise fit. Manufactured to strict ASME B16.5 dimensions, it ensures proper alignment and, when bolted, creates a seal against the flange ring's gasket surface.

The stub end is critical to the ASME B16.5 lap joint flange system:

Role: A welded pipe component with one end flanged to seat the loose flange ring.

Manufacturing: Made from pipe-compatible materials and machined to precise ASME B16.5 dimensions for fit and corrosion resistance.

Function: Its flanged surface contacts the gasket, and bolt force on the loose ring completes the seal.

When using ASME B16.5 lap joint flange, first select the appropriate specification and material of lap joint flange and matching flange short section, bolt, nut, and sealing gasket based on the nominal size, pressure rating, and medium characteristics of the pipeline.

Then, weld the flange short section to the pipeline, ensuring welding quality and avoiding welding defects.

Next, place a sealing gasket on the flange part of the flange short section, and fit the flange body onto the flange short section, aligning the bolt holes of the flange with the bolt holes on the pipeline or equipment.

Afterwards, put on the bolts and nuts, and tighten the bolts evenly according to the specified torque sequence and value, ensuring that the flange sealing surface is tightly fitted with the sealing gasket to achieve sealing. During use, it is necessary to regularly check the sealing condition of the flange and the tightening status of the bolts. If leaks or loose bolts are found, they should be dealt with in a timely manner.

ASME B16.5 flanges serve critical roles across multiple sectors due to their standardized safety and reliability:

Petrochemical Industry: Withstands high pressures and temperatures while handling corrosive crude oil, gases, and refined products.

Natural Gas Industry: Ensures leak-proof integrity in vast pipeline networks for safe transportation and distribution.

Power Industry: Provides dependable performance in critical high-pressure steam lines and cooling water systems within power plants.

Water Treatment Industry: Manages the flow of water and treatment chemicals, often utilizing corrosion-resistant materials.

Food and Pharmaceutical Industries: Meets stringent hygiene protocols with easy-to-clean, sanitary flange designs that prevent bacterial growth.