Views: 58 Author: Site Editor Publish Time: 2025-10-27 Origin: Site

In industrial pipeline systems, butt welded pipe caps serve as important fittings for sealing pipelines and play a crucial role in preventing medium leakage and external impurities from entering. Among them, butt welded pipe caps that comply with ASME B16.9 standards have become important pipeline fittings in fields such as petroleum, chemical, and power due to strict size control, stable structural performance, and extensive material compatibility.

Butt weld cap is a types of butt weld pipe fitting. It used to seal the end of a pipe by welding, preventing fluid leakage and contamination. From the appearance, common butt weld caps are hemispherical, elliptical, disc-shaped, conical, or flat shaped.

From the classification of types, butt weld caps can be divided into carbon steel caps, stainless steel caps, alloy steel caps, etc. according to their materials; According to the manufacturing process, it can be divided into forged pipe caps, stamped pipe caps, and cast pipe caps.

In terms of production and material standards, the manufacturing of welded pipe caps must comply with strict industry standards.

ASME B16.9 and EN 10253 are common production standards;

Common American material standards include ASTM A234, ASTM A403, ASTM A815, etc., to ensure that the material properties of the pipe cap are fully matched with the pipeline system.

ASME B16.9 standard is "Factory Made Wrought Steel Buttwelding Fitings", which is the core specification for the design, manufacturing, and inspection of welded pipe fittings worldwide. Its scope of application covers nominal sizes from 1/2 inch to 48 inches, and wall thickness ranges include SCH 10-SCH 160, XXS; The product range includes butt welded caps, elbows, tees, reducers and other products, compatible with various materials such as carbon steel, stainless steel, alloy steel, etc., and widely used in various industrial pipeline fields.

| Size | 1/2" - 48" / DN15 - 1200 |

| Thickness | SCH 10 - SCH 160, XXS |

| ASME Standard | ANSI / ASME B16.9 / MSS SP 43 |

| JIS Standard | JIS B2311/2312/2313 |

| DIN Standard | DIN2605/2615/2616/2617 |

| EN Standard | EN10253 |

Size and weight are the core technical parameters of ASME B16.9 butt weld caps, which directly affect their compatibility with pipelines and installation stability. In terms of size, the standard is based on nominal size (NPS) and wall thickness, and determines the key dimensions of different specifications of pipe caps: for pipe caps from NPS 1/2 to NPS 48, the standard specifies parameters such as outer diameter (OD), inner diameter (ID), wall thickness (t), top thickness (t1), and groove length (L).

| Nominal Size | outside Diameter at Bevel | Length | Limiting Wall Thickness for Length E | ||

| DN | NPS | OD | E | E1 | |

| 15 | 1/2 | 21.3 | 25 | 25 | 4.57 |

| 20 | 3/4 | 26.7 | 25 | 25 | 3.81 |

| 25 | 1 | 33.4 | 38 | 38 | 4.57 |

| 32 | 1 ¼ | 42.2 | 38 | 38 | 4.83 |

| 40 | 1 ½ | 48.3 | 38 | 38 | 5.08 |

| 50 | 2 | 60.3 | 38 | 44 | 5.59 |

| 65 | 2 ½ | 73.0 | 38 | 51 | 7.11 |

| 80 | 3 | 88.9 | 51 | 64 | 7.62 |

| 90 | 3 ½ | 101.6 | 64 | 76 | 8.13 |

| 100 | 4 | 114.3 | 64 | 76 | 8.64 |

| 125 | 5 | 141.3 | 76 | 89 | 9.65 |

| 150 | 6 | 168.3 | 89 | 102 | 10.92 |

| 200 | 8 | 219.1 | 102 | 127 | 12.70 |

| 250 | 10 | 273.0 | 127 | 152 | 12.70 |

| 300 | 12 | 323.8 | 152 | 178 | 12.70 |

| 350 | 14 | 355.6 | 165 | 191 | 12.70 |

| 400 | 16 | 406.4 | 178 | 203 | 12.70 |

| 450 | 18 | 457.0 | 203 | 229 | 12.70 |

| 500 | 20 | 508.0 | 229 | 254 | 12.70 |

| 550 | 22 | 559.0 | 254 | 254 | 12.70 |

| 600 | 24 | 610.0 | 267 | 305 | 12.70 |

| 650 | 26 | 660.0 | 267 | ﹍ | ﹍ |

| 700 | 28 | 711.0 | 267 | ﹍ | ﹍ |

| 750 | 30 | 762.0 | 267 | ﹍ | ﹍ |

| 800 | 32 | 813.0 | 267 | ﹍ | ﹍ |

| 850 | 34 | 864.0 | 267 | ﹍ | ﹍ |

| 900 | 36 | 914.0 | 267 | ﹍ | ﹍ |

| 950 | 38 | 965.0 | 305 | ﹍ | ﹍ |

| 1000 | 40 | 1016.0 | 305 | ﹍ | ﹍ |

| 1050 | 42 | 1067.0 | 305 | ﹍ | ﹍ |

| 1100 | 44 | 1118.0 | 343 | ﹍ | ﹍ |

| 1150 | 46 | 1168.0 | 343 | ﹍ | ﹍ |

| 1200 | 48 | 1219.0 | 343 | ﹍ | ﹍ |

| Size | NPS | Sch20 | Sch30 | STD | Sch40 | Sch60 | XS | Sch80 | Sch100 | Sch120 | Sch140 | Sch160 | XXS |

| DN | |||||||||||||

| 15 | 1/2 | 0.04 | 0.04 | 0.04 | 0.06 | 0.06 | 0.08 | 0.11 | |||||

| 20 | 3/4 | 0.05 | 0.05 | 0.05 | 0.07 | 0.07 | 0.11 | 0.15 | |||||

| 25 | 1 | 0.1 | 0.12 | 0.12 | 0.16 | 0.16 | 0.22 | 0.32 | |||||

| 32 | 1 ¼ | 0.13 | 0.16 | 0.16 | 0.22 | 0.22 | 0.28 | 0.43 | |||||

| 40 | 1 ½ | 0.16 | 0.19 | 0.19 | 0.26 | 0.26 | 0.36 | 0.52 | |||||

| 50 | 2 | 0.21 | 0.26 | 0.26 | 0.36 | 0.36 | 0.57 | 0.73 | |||||

| 65 | 2 ½ | 0.4 | 0.44 | 0.44 | 0.59 | 0.59 | 0.80 | 1.18 | |||||

| 80 | 3 | 0.65 | 0.73 | 0.73 | 1.08 | 1.08 | 1.48 | 2.02 | |||||

| 90 | 3 ½ | 0.9 | 1.07 | 1.07 | 1.51 | 1.51 | |||||||

| 100 | 4 | 1.04 | 1.30 | 1.30 | 1.85 | 1.85 | 2.4 | 2.91 | 3.69 | ||||

| 125 | 5 | 2.10 | 2.10 | 3.06 | 3.06 | 4.07 | 5.09 | 6.1 | |||||

| 150 | 6 | 3.19 | 3.19 | 4.93 | 4.93 | 6.41 | 8.2 | 9.86 | |||||

| 200 | 8 | 4.45 | 4.92 | 5.72 | 5.72 | 7.21 | 8.88 | 8.88 | 10.6 | 12.8 | 14.5 | 16.1 | 15.6 |

| 250 | 10 | 6.89 | 8.46 | 10.1 | 10.1 | 13.9 | 13.8 | 16.4 | 19.8 | 23.3 | 27.6 | 31 | 27.6 |

| 300 | 12 | 9.75 | 12.9 | 14.6 | 15.9 | 21.9 | 19.5 | 26.9 | 32.9 | 39 | 43.9 | 51.2 | 39 |

| 350 | 14 | 14.6 | 17.6 | 17.5 | 20.5 | 27.7 | 23.3 | 35 | 43.8 | 51.1 | 58.4 | 65.7 | |

| 400 | 16 | 18.3 | 22.1 | 22.1 | 29.4 | 38.6 | 29.4 | 49.7 | 60.7 | 71.7 | 84.6 | 93.8 | |

| 450 | 18 | 23.4 | 32.9 | 28.2 | 42.2 | 56.3 | 37.5 | 70.4 | 86.8 | 103 | 117 | 134 | |

| 500 | 20 | 35.1 | 46.8 | 35.1 | 55.6 | 76.0 | 46.8 | 96.5 | 120 | 141 | 164 | 184 | |

| 550 | 22 | 42.7 | 56.9 | 42.7 | 99.7 | 57.0 | 128 | 157 | 185 | 214 | 242 | ||

| 600 | 24 | 49.7 | 74.5 | 49.7 | 91.2 | 129 | 66.3 | 162 | 203 | 240 | 273 | 311 | |

| 650 | 26 | 74.0 | 55.6 | 74.1 | |||||||||

| 700 | 28 | 82.4 | 103 | 61.8 | 82.4 | ||||||||

| 750 | 30 | 91.2 | 114 | 68.5 | 91.2 | ||||||||

| 800 | 32 | 101 | 126 | 75.4 | 138 | 101 | |||||||

| 850 | 34 | 110 | 138 | 82.7 | 152 | 110 | |||||||

| 900 | 36 | 120 | 150 | 90.2 | 180 | 120 | |||||||

| 950 | 38 | 104 | 139 | ||||||||||

| 1000 | 40 | 113 | 150 | ||||||||||

| 1050 | 42 | 122 | 162 | ||||||||||

| 1100 | 44 | 138 | 184 | ||||||||||

| 1150 | 46 | 148 | 197 | ||||||||||

| 1200 | 48 | 158 | 210 |

ASTM A234 WPB is the most widely used carbon steel butt welded pipe material, with a chemical composition mainly composed of carbon (≤ 0.30%) and manganese (0.29% -1.06%). It has excellent mechanical properties, with a tensile strength of ≥ 415MPa and a yield strength of ≥ 240MPa. This material cap has good welding performance and can be reliably connected using conventional welding processes such as arc welding and gas shielded welding. It is also cost-effective and suitable for pipeline systems that transport neutral or weakly corrosive media such as water, steam, oil, and natural gas, such as process pipelines in petrochemical plants, urban heating pipelines, and steam and water pipelines in power plants.

Chemical Composition

| CHEMICAL | LIMITS | C | Mn | P | S | Si | Cr | Mo | Ni | Cu | V |

| ASTM A234 WPB | MIN | 0.29 | 0.10 | ||||||||

| MAX | 0.30 | 1.06 | 0.050 | 0.058 | 0.40 | 0.15 | 0.40 | 0.40 | 0.08 |

Mechanical Properties

| MATERIAL | T.S (MPA) | Y.S (MPA) | EL % | HARDNESS |

| ASTM A234 WPB | 415 min | 240 min | 22 min | 197 max |

In terms of manufacturing and inspection, ASTM A234 WPB carbon steel pipe caps need to undergo hot forging, normalizing treatment (to eliminate internal stress), surface shot blasting and rust removal processes. The finished products need to pass inspection items such as hydrostatic testing (test pressure is 1.5 times the nominal pressure) and magnetic particle testing (to detect surface cracks) to ensure no leakage or defects.

The ASTM A403 standard covers various stainless steel materials such as austenitic stainless steel and duplex stainless steel for welded pipe fittings, among which the most commonly used materials are WP304 (18-8 stainless steel) and WP316 (18-10-2 stainless steel). WP304 stainless steel pipe cap contains 18% -20% chromium and 8% -11% nickel, with excellent oxidation resistance and general corrosion resistance. It can be used in a wide temperature range from -270 ℃ to 870 ℃; WP316 stainless steel pipe caps have significantly improved resistance to pitting and intergranular corrosion due to the addition of 2% -3% molybdenum element. They are particularly suitable for corrosive media environments containing chloride ions and sulfate ions, such as seawater treatment pipelines, chemical acid and alkali transportation pipelines, and food and pharmaceutical production equipment pipelines.

Chemical Composition

| CHEMICAL | LIMITS | C | Mn | P | S | Si | Ni | Cr | Mo |

| ASTM A403 WP304 | MIN | 8.0 | 18.0 | ||||||

| MAX | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 11.0 | 20.0 | ||

| ASTM A403 WP304L | MIN | 8.0 | 18.0 | ||||||

| MAX | 0.03 | 2.00 | 0.045 | 0.030 | 1.00 | 11.0 | 20.0 | ||

| ASTM A403 WP316 | MIN | 10.00 | 16.00 | 2.00 | |||||

| MAX | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 14.00 | 18.00 | 3.00 | |

| ASTM A403 WP316L | MIN | 10.00 | 16.00 | 2.00 | |||||

| MAX | 0.03 | 2.00 | 0.045 | 0.030 | 1.00 | 14.00 | 18.00 | 3.00 |

Mechanical Properties

| MATERIAL | ASTM A403 WP304 | ASTM A403 WP304L |

| T.S (MPA) | 515 min | 485 min |

| Y.S (MPA) | 205 min | 170 min |

| EL % | 28 min | 28 min |

| MATERIAL | ASTM A403 WP316 | ASTM A403 WP316L |

| T.S (MPA) | 515 min | 485 min |

| Y.S (MPA) | 205 min | 170 min |

| EL % | 28 min | 28 min |

The manufacturing process of this material cap focuses on surface quality control. After forming, it needs to undergo solution treatment (1010 ℃ -1150 ℃ water quenching) to restore the corrosion resistance of stainless steel. The surface roughness should reach Ra ≤ 6.3 μ m to avoid corrosion caused by medium adhesion. In terms of inspection, in addition to conventional dimensional testing and hydrostatic testing, intergranular corrosion testing (such as ASTM A262 E method) is also required to ensure that intergranular corrosion cracking does not occur in high-temperature environments.

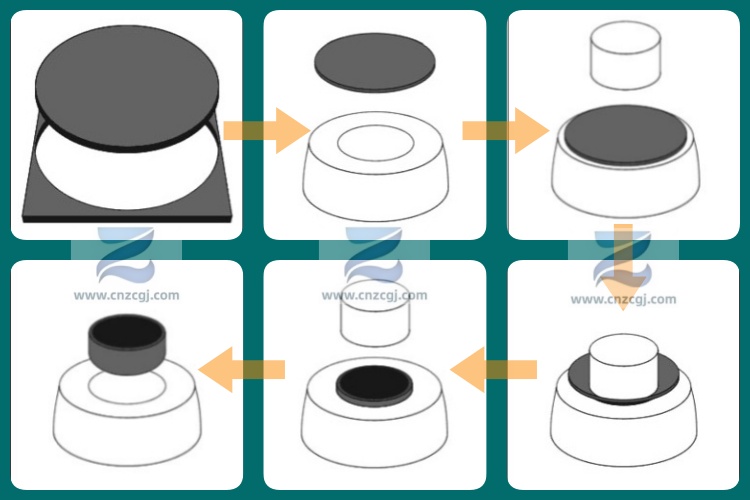

1. Raw material inspection and cutting

2. Heating and Forming

3. Heat treatment

4. Groove processing and dimensional finishing

5. Surface treatment and final inspection

ASME B16.9 butt welded pipe caps are widely used in various industrial fields due to their standardized design, multi material compatibility, and reliable sealing performance

Oil and gas industry: used for terminal sealing of wellhead equipment for oil and gas extraction, maintenance endpoints of long-distance pipelines, and process pipelines of catalytic cracking and hydrogenation units in refineries;

Chemical industry: suitable for sealing the inlet and outlet of pipelines transporting acidic and alkaline solutions, organic solvents, as well as reaction vessels and storage tanks;

Power industry: used for steam and feedwater pipeline terminals in thermal power plants and nuclear power plants, as well as connection ports for condensers and heat exchangers;

Food and pharmaceutical industry: ASTM A403 stainless steel pipe caps can be used for sterile piping systems in food and beverage transportation and drug production due to their sanitary surface treatment;

In addition, ASME B16.9 butt weld caps also play an irreplaceable sealing role in municipal engineering (urban gas pipelines, water pipelines), shipbuilding (ship ballast water pipelines, fuel pipelines), metallurgical industry (steelmaking cooling water pipelines) and other fields.

ASME B16.9 butt weld cap, as a key component of industrial pipeline systems, has standardized manufacturing specifications, strict size control, and diverse material selection, which enable it to meet the sealing requirements under different working conditions and provide solid guarantees for the safe and stable operation of pipeline systems.