Views: 29 Author: Site Editor Publish Time: 2025-08-28 Origin: Site

ASME B16.9 butt weld tee is widely used in industrial pipeline systems, occupying a place in industrial pipeline construction with strict production standards, diverse product types, and advanced production processes.

ASME B16.9 is a manufacturing standard for forged steel butt welded pipe fittings developed by the American Society of Mechanical Engineers (ASME). This standard has a high degree of recognition and authority worldwide, providing a unified and standardized technical basis for the design, production, inspection, and other aspects of welded pipe fittings.

The ASME B16.9 standard covers a wide range of products, mainly including various specifications of ASME B16.9 butt weld tee, elbows reducers, caps,etc. The size range of these fittings is from 1/2” (12.7 mm) to 48” (1219.2 mm), which can meet the needs of different piping systems.

ASME B16.9 standard covers multiple key elements in the manufacturing of butt weld fittings. In terms of dimensional tolerances, the allowable deviations for the outer diameter, inner diameter, wall thickness, length, angle, and other dimensions of welded pipe fittings are clearly defined to ensure that the fittings can be accurately matched with other components in the pipeline system, ensuring the sealing and stability of the connection.

| Shape Type | Equal Tee and Reducing Tee |

| Size Range | 1/2" - 48" / DN15 - DN1200 |

| Thickness Schedule | SCH 10 - SCH 160, XXS |

| Standard | ANSI / ASME B16.9, MSS SP 43, JIS B2311/2312/2313, DIN2605/2615/2616/2617, EN10253 |

| Carbon Steel | ASTM A234 WPB/WPC, A420 WPL6 |

| API 5L Grades | ASTM A860 WPHY 42 / 46 / 56 / 60 / 65 |

| Alloy Steel | ASTM A234 WP11 / WP12 / WP 5 / WP9 / WP91 / WP92,15CrMoG, 12Cr1MoVG, 12Cr5Mo, 1Cr5Mo, Cr9Mo, 10CrMo910, 12CrMo4-5 |

| Stainless Steel | ASTM A403 WP304/304L/304H, 316/316L, 310S, 317,347, 904L, A815 S32205, S31803, 32750, 32760 |

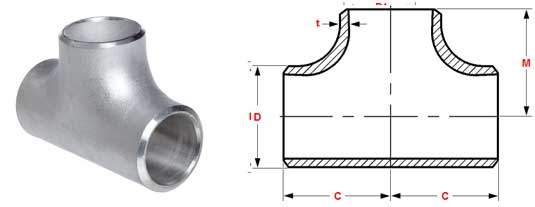

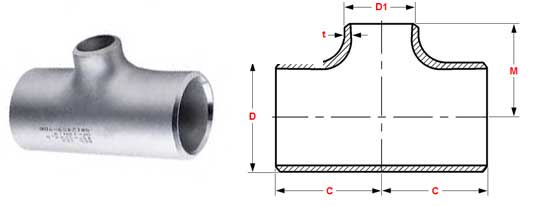

| Nominal Size | Outside Diameter at Bevel | Center to End | ||

| DN | NPS | OD1×OD2 | C | M |

| 15 | 1/2 | 21.3 | 25 | 25 |

| 20 | 3/4 | 26.7 | 29 | 29 |

| 25 | 1 | 33.4 | 38 | 38 |

| 32 | 11/4 | 42.2 | 48 | 48 |

| 40 | 11/2 | 48.3 | 57 | 57 |

| 50 | 2 | 60.3 | 64 | 64 |

| 65 | 21/2 | 73.0 | 76 | 76 |

| 80 | 3 | 88.9 | 86 | 86 |

| 90 | 31/2 | 101.6 | 95 | 95 |

| 100 | 4 | 114.3 | 105 | 105 |

| 125 | 5 | 141.3 | 124 | 124 |

| 150 | 6 | 168.3 | 143 | 143 |

| 200 | 8 | 219.1 | 178 | 178 |

| 250 | 10 | 273.0 | 216 | 216 |

| 300 | 12 | 323.8 | 254 | 254 |

| 350 | 14 | 355.6 | 279 | 279 |

| 400 | 16 | 406.4 | 305 | 305 |

| 450 | 18 | 457.0 | 343 | 343 |

| 500 | 20 | 508.0 | 381 | 381 |

| 550 | 22 | 559.0 | 419 | 419 |

| 600 | 24 | 610.0 | 432 | 432 |

| 650 | 26 | 660.0 | 495 | 495 |

| 700 | 28 | 711.0 | 521 | 521 |

| 750 | 30 | 762.0 | 559 | 559 |

| 800 | 32 | 813.0 | 597 | 597 |

| 850 | 34 | 864.0 | 635 | 635 |

| 900 | 36 | 914.0 | 673 | 673 |

| 950 | 38 | 965.0 | 711 | 711 |

| 1000 | 40 | 1016.0 | 749 | 749 |

| 1050 | 42 | 1067.0 | 762 | 711 |

| 1100 | 44 | 1118.0 | 813 | 762 |

| 1150 | 46 | 1168.0 | 851 | 800 |

| 1200 | 48 | 1219.0 | 889 | 838 |

Nominal Size | All Fittings | 45°&90° Elbows & Tees, Crosses | 3D Radius Elbows | Returns | Caps | Reducers & Lap Joint Stub Ends | Lap Joint Stub Ends | ||||||

| DN | NPS | OD 3) 4) | ID 3) | A B C M | A B |  O O | K | U | E, E1 | H F |  G G | R | t |

| 15-65 | 1/2 -21/2 | +1.6 -0.8 | ± 0.8 | ± 2 | ± 3 | ± 6 | ± 6 | ± 1 | ± 3 | ± 2 | 0 -1 | 0 -1 | +1.6 0 |

| 80-90 | 3-31/2 | ± 1.6 | ± 1.6 | ± 2 | ± 3 | ± 6 | ± 6 | ± 1 | ± 3 | ± 2 | 0 -1 | 0 -1 | +1.6 0 |

| 100 | 4 | ± 1.6 | ± 1.6 | ± 2 | ± 3 | ± 6 | ± 6 | ± 1 | ± 3 | ± 2 | 0 -1 | 0 -2 | +1.6 0 |

| 125-200 | 5-8 | +2.4 -1.6 | ± 1.6 | ± 2 | ± 3 | ± 6 | ± 6 | ± 1 | ± 6 | ± 2 | 0 -1 | 0 -2 | +1.6 0 |

| 250-450 | 10-18 | +4.0 -3.2 | ± 3.2 | ± 2 | ± 3 | ± 10 | ± 6 | ± 2 | ± 6 | ± 2 | 0 -2 | 0 -2 | +3.2 0 |

| 500-600 | 20-24 | +6.4 -4.8 | ± 4.8 | ± 2 | ± 3 | ± 10 | ± 6 | ± 2 | ± 6 | ± 2 | 0 -2 | 0 -2 | +3.2 0 |

| 650-750 | 26-30 | +6.4 -4.8 | ± 4.8 | ± 3 | ± 6 | --- | --- | --- | ± 10 | ± 5 | --- | --- | --- |

| 800-1200 | 32-48 | +6.4 -4.8 | ± 4.8 | ± 5 | ± 6 | --- | --- | --- | ± 10 | ± 5 | --- | --- | --- |

| 1300-1500 | 52-60 | +6.4 -4.8 | ± 4.8 | ± 5 | --- | --- | --- | --- | --- | --- | --- | --- | --- |

| 1600-1700 | 64-68 | +6.4 -4.8 | ± 4.8 | ± 5 | --- | --- | --- | --- | --- | --- | --- | --- | --- |

| 1800-2000 | 72-80 | +6.4 -4.8 | ± 4.8 | ± 5 | --- | --- | --- | --- | --- | --- | --- | --- | --- |

ASME B16.9 standard also specifies requirements for the surface quality and pressure testing of pipe fittings. In terms of surface quality, the inner and outer surfaces of the pipe fittings should be smooth and free from defects such as cracks, folds, scratches, etc; Pressure testing requires pipe fittings to undergo hydrostatic or pneumatic testing at a specified pressure to verify their sealing and pressure resistance performance, ensuring that there will be no leakage or other issues during use.

ASME B16.9 butt weld tee can be classified into various types according to different classification methods. According to material classification, there are mainly carbon steel, alloy steel, and stainless steel.

Carbon steel materials have good toughness and weldability, and are relatively inexpensive. They are suitable for general industrial pipeline systems, such as pipelines transporting media such as water, steam, and oil.

Chemical Composition

| CHEMICAL | LIMITS | C | Mn | P | S | Si | Cr | Mo | Ni | Cu | Cb | V |

| ASTM A234 WPB | MIN | 0.29 | 0.10 | |||||||||

| MAX | 0.30 | 1.06 | 0.050 | 0.058 | 0.40 | 0.15 | 0.40 | 0.40 | / | 0.08 | ||

| ASTM A420 WPL6 | MIN | 0.50 | 0.15 | |||||||||

| MAX | 0.30 | 1.35 | 0.035 | 0.040 | 0.40 | 0.40 | 0.30 | 0.12 | 0.40 | 0.02 | 0.08 |

Mechanical Properties

| MATERIAL | T.S (MPA) | Y.S (MPA) | EL % | HARDNESS |

| ASTM A234 WPB | 415 min | 240 min | 22 min | 197 max |

| ASTM A420 WPL6 | 415-655 | 240 min | 30min |

Alloy steel materials improve the strength, hardness, corrosion resistance, and other properties of welded tees by adding alloying elements such as chromium, nickel, and molybdenum. They are suitable for high-pressure, high-temperature, and highly corrosive working environments, such as high-pressure hydrogenation pipelines in the petrochemical industry and high-temperature steam pipelines in the power industry;

Chemical Composition

| CHEMICAL | LIMITS | C | Mn | P | S | Si | Cr | Mo |

| ASTM A234 WP12 | MIN | 0.050 | 0.30 | 0.80 | 0.440 | |||

| MAX | 0.200 | 0.80 | 0.045 | 0.045 | 0.60 | 1.25 | 0.650 | |

| ASTM A234 WP11 CL1 | MIN | 0.050 | 0.30 | 0.50 | 1.00 | 0.440 | ||

| MAX | 0.150 | 0.60 | 0.030 | 0.030 | 1.00 | 1.50 | 0.660 | |

| ASTM A234 WP22 CL1,CL3 | MIN | 0.050 | 0.30 | 1.90 | 0.870 | |||

| MAX | 0.150 | 0.60 | 0.040 | 0.040 | 0.50 | 2.60 | 1.130 |

Mechanical Properties

| MATERIAL | T.S (MPA) | Y.S (MPA) | EL % |

| ASTM A234 WP11 CL1 | 415 min | 205 min | 30min |

| ASTM A234 WP12 CL1 | 415 min | 220min | 30min |

| ASTM A234 WP12 CL2 | 485 min | 275 min | 30min |

| ASTM A234 WP22 CL1 | 415 min | 205 min | 30min |

| ASTM A234 WP22 CL3 | 520min | 310min | 30min |

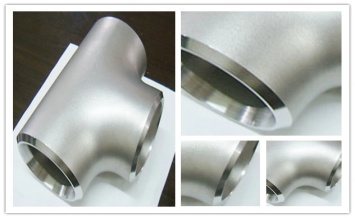

Stainless steel butt weld tee have excellent corrosion resistance and beautiful surfaces, suitable for pipelines transporting corrosive media, such as acid and alkali solution pipelines in the chemical industry and sanitary grade pipelines in the food and pharmaceutical industry.

Chemical Composition

| CHEMICAL | LIMITS | C | Mn | P | S | Si | Ni | Cr |

| ASTM A403 WP304 | MIN | 8.0 | 18.0 | |||||

| MAX | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 11.0 | 20.0 | |

| ASTM A403 WP304L | MIN | 8.0 | 18.0 | |||||

| MAX | 0.03 | 2.00 | 0.045 | 0.030 | 1.00 | 11.0 | 20.0 |

Mechanical Properties

| MATERIAL | ASTM A403 WP304 | ASTM A403 WP304L |

| T.S (MPA) | 515 min | 485 min |

| Y.S (MPA) | 205 min | 170 min |

| EL % | 28 min | 28 min |

According to the ratio of the diameter of the branch pipe to the main pipe, ASME B16.9 butt weld tee can be divided into equal diameter tees and reducing diameter tees.

The three openings of the equal diameter tee have the same diameter and are suitable for connecting three pipes of the same diameter to achieve equal diameter diversion or merging of media;

The three principles of reducing diameter refer to the different diameters of branch pipes and main pipes, which can meet the connection requirements between pipes of different diameters, achieve variable diameter diversion or merging of media in the pipeline system, and improve the flexibility and adaptability of the pipeline system.

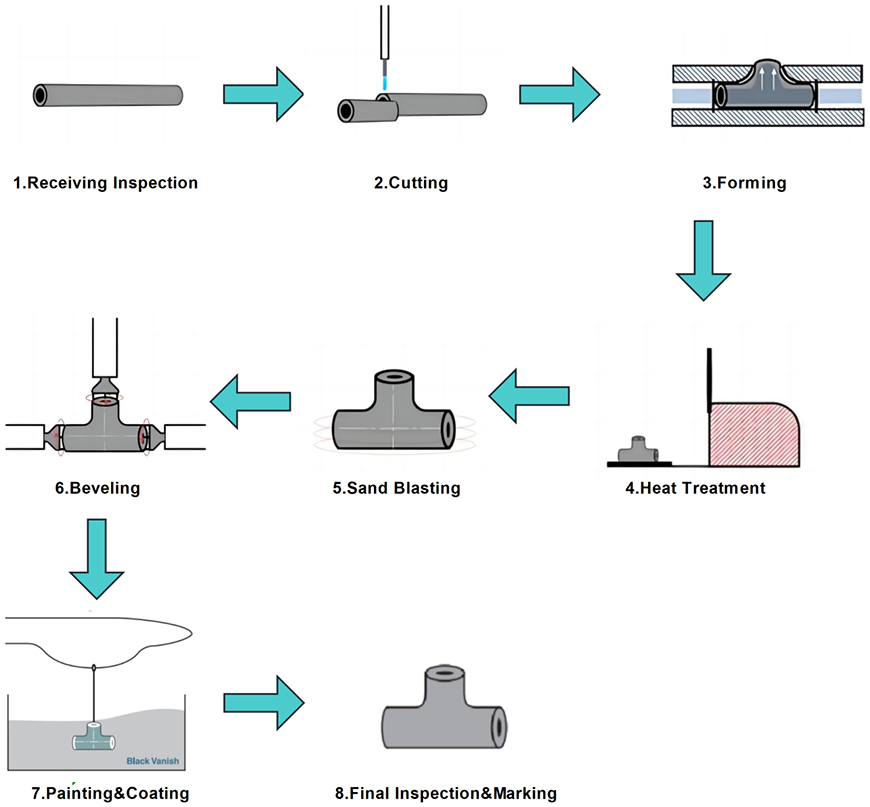

The manufacturing process of ASME B16.9 butt weld tee is complex and rigorous, mainly including the following key steps:

According to the material requirements of the product, select high-quality steel that meets the ASME B16.9 standard as the raw material. Raw materials need to undergo strict inspections, including chemical composition analysis, mechanical property testing, etc., to ensure that their quality meets standard requirements. Only qualified raw materials can enter the subsequent production process, ensuring product quality from the source.

By hydraulic bulging, the middle part of a pipe with the same diameter as the three-way main pipe is placed into a hydraulic forming mold. Ultra high pressure liquid is injected into the pipe blank, and axial thrust is applied at both ends of the pipe blank to replenish the material. Under the combined action of liquid pressure and axial thrust, the metal of the tube blank flows towards the mold cavity (branch direction), ultimately forming a three-way blank. The three-way blank still needs to undergo preliminary cleaning to remove surface oxide scale and impurities.

In order to eliminate the internal stress generated during the forging process and improve the mechanical properties of the tee, it is necessary to perform heat treatment on the forged tee blank. The heat treatment process depends on different materials and usually includes three stages: heating, insulation, and cooling. During the heat treatment process, it is necessary to precisely control the heating temperature, holding time, and cooling rate to ensure that the tee can achieve the expected mechanical performance indicators, such as hardness, strength, toughness, etc.

After heat treatment, the three-way blank needs to be machined to meet the size and accuracy requirements specified by the standard. Mechanical processing mainly includes turning, milling, drilling and other processes, through which the various openings, end faces, inner and outer surfaces of the tee are machined to ensure that the dimensional tolerances and surface roughness of the tee comply with the provisions of ASME B16.9 standard.

Inspection and testing are carried out throughout the production process of ASME B16.9 butt welded tees. In addition to raw material inspection, intermediate inspection during forging process, performance inspection after heat treatment, and dimensional inspection after mechanical processing, finished products also need to undergo final inspection and testing, including appearance inspection, dimensional review, pressure testing, non-destructive testing, etc.

ASME B16.9 butt weld tee have many significant characteristics.

Firstly, reliable quality is one of its core characteristics. Due to strict adherence to ASME B16.9 standards in production and manufacturing, there are strict specifications and requirements for the selection of raw materials, control of production processes, and inspection and testing of products, ensuring that every product meets high-quality standards and can operate stably in various harsh working environments, reducing the risk of pipeline system failures.

Secondly, it has excellent performance. ASME B16.9 butt weld tee have high strength and stiffness, can withstand significant pressure and temperature changes, and are not easily deformed or damaged during long-term use. At the same time, its good sealing performance can effectively prevent medium leakage, ensure the safe operation of pipeline systems, and reduce economic losses and environmental hazards caused by leakage.

In addition, it has strong universality. The butt welded tee specifications under this standard are complete and can meet the needs of different pipeline systems. It has been widely recognized and applied worldwide, facilitating cooperation and communication in pipeline engineering between different countries and regions, and reducing the troubles and costs caused by inconsistent standards.

ASME B16.9 butt weld tee have a wide range of applications due to their excellent performance and reliable quality, covering multiple important industries:

Petrochemical Industry

Power and Energy Industry

Metallurgical Industry

Shipbuilding Industry

Urban Infrastructure Construction