Views: 66 Author: Site Editor Publish Time: 2023-10-31 Origin: Site

ASTM A182 F51 is a high-strength and corrosion-resistant stainless steel material. It is a duplex stainless steel with a high Cr content and an appropriate amount of alloy elements such as Ni and Mo. These elements can form a strong corrosion-resistant layer to prevent the medium from corroding the material. The main characteristics of ASTM A182 F51 include corrosion resistance, excellent mechanical properties, weldability and processability.

ASTM A182 F51 is equivalent to UNS S31803 or DIN 1.4462. This is the original name for 22% Cr duplex stainless steel, S31803 is the Unified Numbering System (UNS) designation for the original duplex stainless steel. The UNS system was created by multiple trade groups in the 1970s to reduce confusion caused by the same alloy being called different things and vice versa. Each metal is represented by a letter followed by five numbers, where the letter represents the metal family, i.e. S for stainless steel.

The Characteristics of ASTM A182 F51 Material

Chemical composition

CHEMICAL | C | Mn | p | S | Si | Cr | Ni | Mo | N |

ASTM A182 F51 | 0.030max | 2.00max | 0.030max | 0.020max | 1.00max | 21.0-23.0 | 4.5-6.5 | 2.5-3.5 | 0.08-0.20 |

Chromium is one of the most important alloying elements in stainless steel. It can form a dense protective film of chromium oxide (Cr₂O₃) on the surface of the material. This film has strong stability and can prevent oxygen and other corrosive media from further corroding the interior of the material, thus giving the material good corrosion resistance.

The addition of nickel helps to stabilize the austenite phase and works together with chromium to adjust the microstructure of the material. Nickel can improve the toughness, ductility and corrosion resistance of the material.

Mechanical properties

GRADE | ASTM A182 F51 |

Tensile strength | 620 min |

Yield strength | 450 min |

Elongation% | 25 min |

Reduction of area% | 45 min |

ASTM A182 F51 flange has a high yield strength, which enables it to withstand large external forces without plastic deformation. In the pipeline system, high yield strength means that it can withstand the pressure inside the pipeline, external loads, and stress that may occur during installation and operation.

A182 F51 Flange Pressure Rating Table

Table Il-2-2.8 Pressure-Temperature Ratings for Group 2.8 Materials | |||||||

Nominal Designation | Forgings | Castings | Plates | ||||

22Cr-5Ni-3Mo-N | A182 Gr.F51(1) | A240 Gr.S31803(1) | |||||

Working Pressures by Classes,psig | |||||||

Class | |||||||

Temp.,F | 150 | 300 | 400 | 600 | 900 | 1500 | 2500 |

-20 to 100 | 290 | 750 | 1000 | 1500 | 2250 | 3750 | 6250 |

200 | 260 | 745 | 990 | 1490 | 2230 | 3720 | 6200 |

300 | 230 | 665 | 890 | 1335 | 2000 | 3335 | 5560 |

400 | 200 | 615 | 820 | 1230 | 1845 | 3070 | 5120 |

500 | 170 | 580 | 775 | 1160 | 1740 | 2905 | 4840 |

600 | 140 | 555 | 740 | 1115 | 1670 | 2785 | 4640 |

650 | 125 | 545 | 730 | 1095 | 1640 | 2735 | 4560 |

700 | 110 | 540 | 725 | 1085 | 1625 | 2710 | 4520 |

750 | 95 | 530 | 710 | 1065 | 1595 | 2660 | 4430 |

Classification of ASTM A182 F51 Flanges

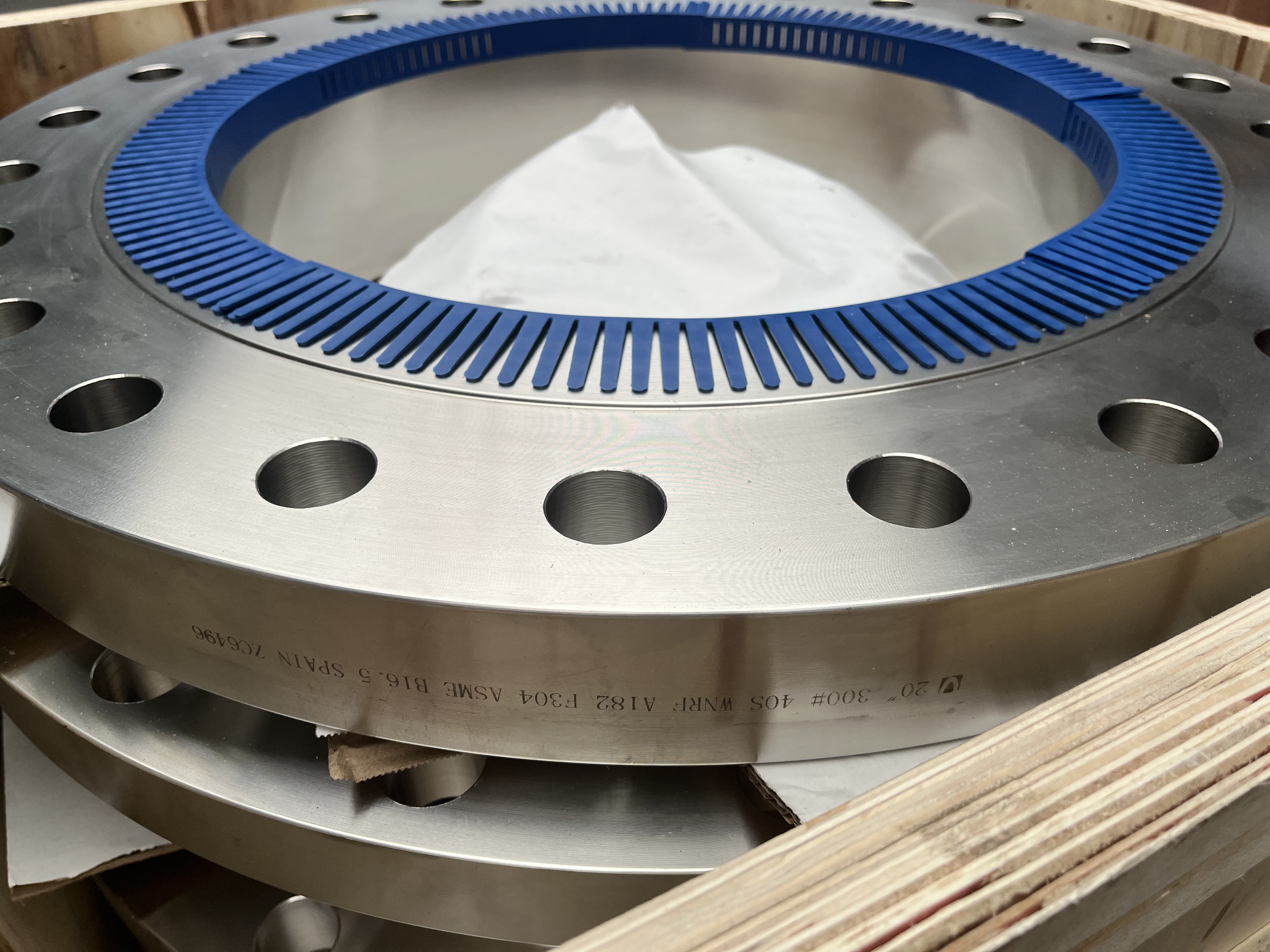

ASTM A182 F51 flanges can be divided into six categories: duplex stainless steel blind flanges, slip on flanges, socket weld flanges, threaded flanges, weld neck flanges, and lap joint flanges.

Blind flange: A blind flange is a solid flange with no holes for fluid to pass through.

Socket weld flange: A socket weld flange has a socket and spigot structure.

Threaded flange: The main feature of a threaded flange is that it is connected by threads. It has internal or external threads and is connected to pipes or pipe fittings with corresponding external or internal threads.

Weld neck flange: A weld neck flange is connected by butt welding the flange to the pipe.

Lap joint flange: A lap joint flange uses a flange, steel ring, etc. to put the flange on the pipe end so that the flange can move on the pipe end.

Slip on flange: A slip on flange is a flange that connects the flange to the pipe through a fillet weld.

Adavantages of ASTM A182 F51 Duplex Stainless Steel Flange

Excellent mechanical properties

Corrosion resistance

Durable connection

Suitable for high pressure and high heat applications.

Ease of installation.

ASTM A182 F51 duplex stainless steel flanges are widely used in fields such as chemical, marine, petroleum, natural gas, and food processing, especially in high-temperature, high-pressure, and highly corrosive environments, which have irreplaceable advantages.