Views: 23 Author: Site Editor Publish Time: 2025-12-05 Origin: Site

ASME B16.5 is a production standard for pipe flanges and flange fittings, which specifies the quality control and standardized design of forged steel flanges.

Forged steel flanges are widely used in industrial fields such as petrochemicals, electricity, oil and gas transportation, and shipbuilding.

ASME B16.5 "Pipe Flanges and Flanged Fittings", developed by the American Society of Mechanical Engineers (ASME), is one of the widely used steel flange standards in the global petroleum, chemical, power, metallurgical and other fields.

This standard specifies the material, dimensional parameters, tolerance range, pressure and temperature rating, marking specifications, and inspection technical requirements for steel flanges.

Dimension:NPS 1/2 to NPS 24.

Pressure:Class 150, 300, 400, 600, 900, 1500, and 2500.

Types:weld neck flange, slip on flange, socket weld flange, threaded, lap joint flange, and blind flange.

Attention: Flange diameter>DN600, refer to specialized standards for large-sized flanges such as ASME B16.47.

The Significance of Standard Specifications

Following the ASME B16.5 standard means that flange products have a high degree of interchangeability and consistency in size, sealing performance, and load-bearing capacity.

ASME B16.5 forged steel flanges have become an important component of high-pressure and high-temperature industrial pipeline construction due to their excellent mechanical properties and standardized design. According to different purposes and connection methods, forged flanges are mainly divided into the following six types:

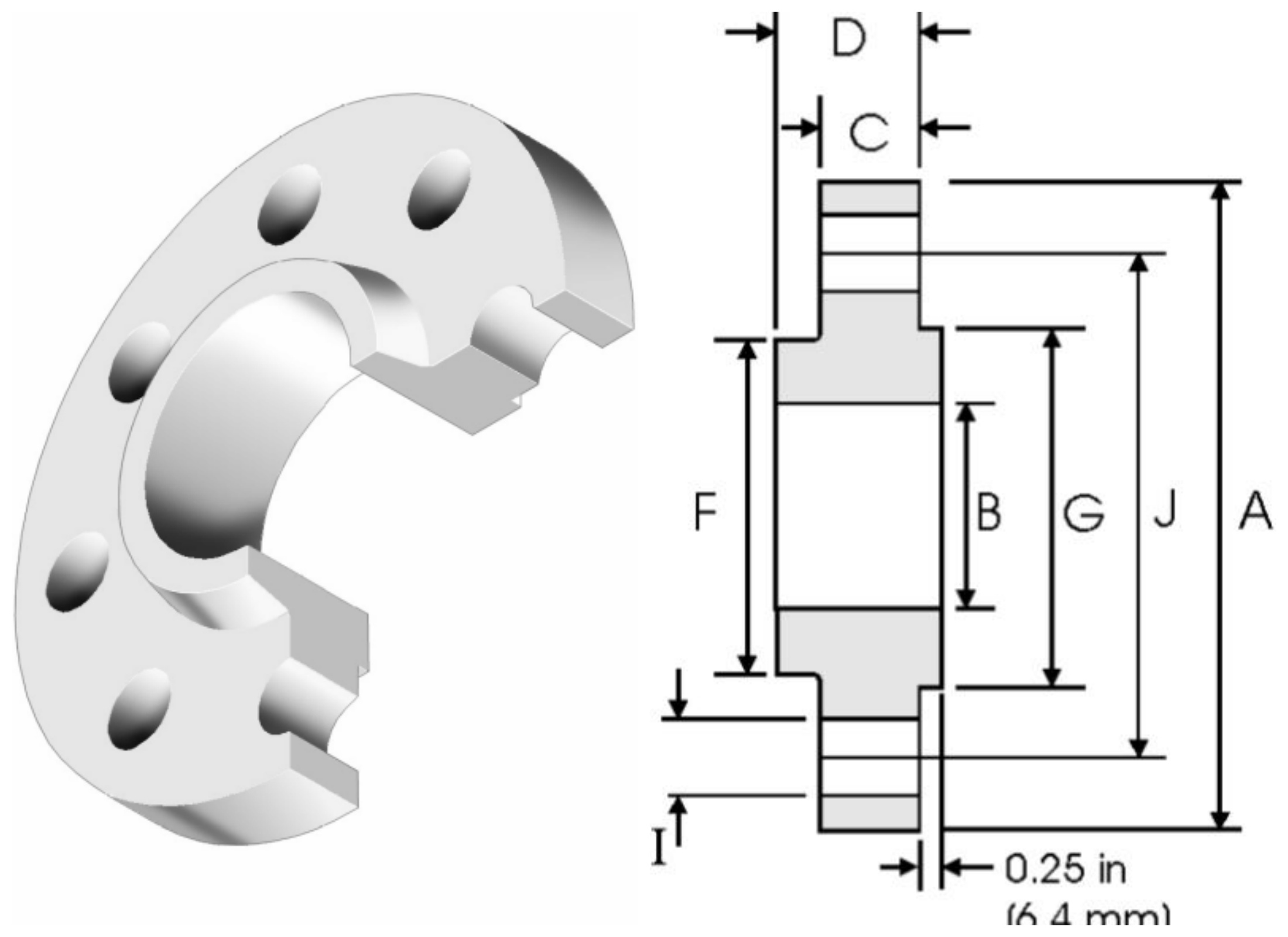

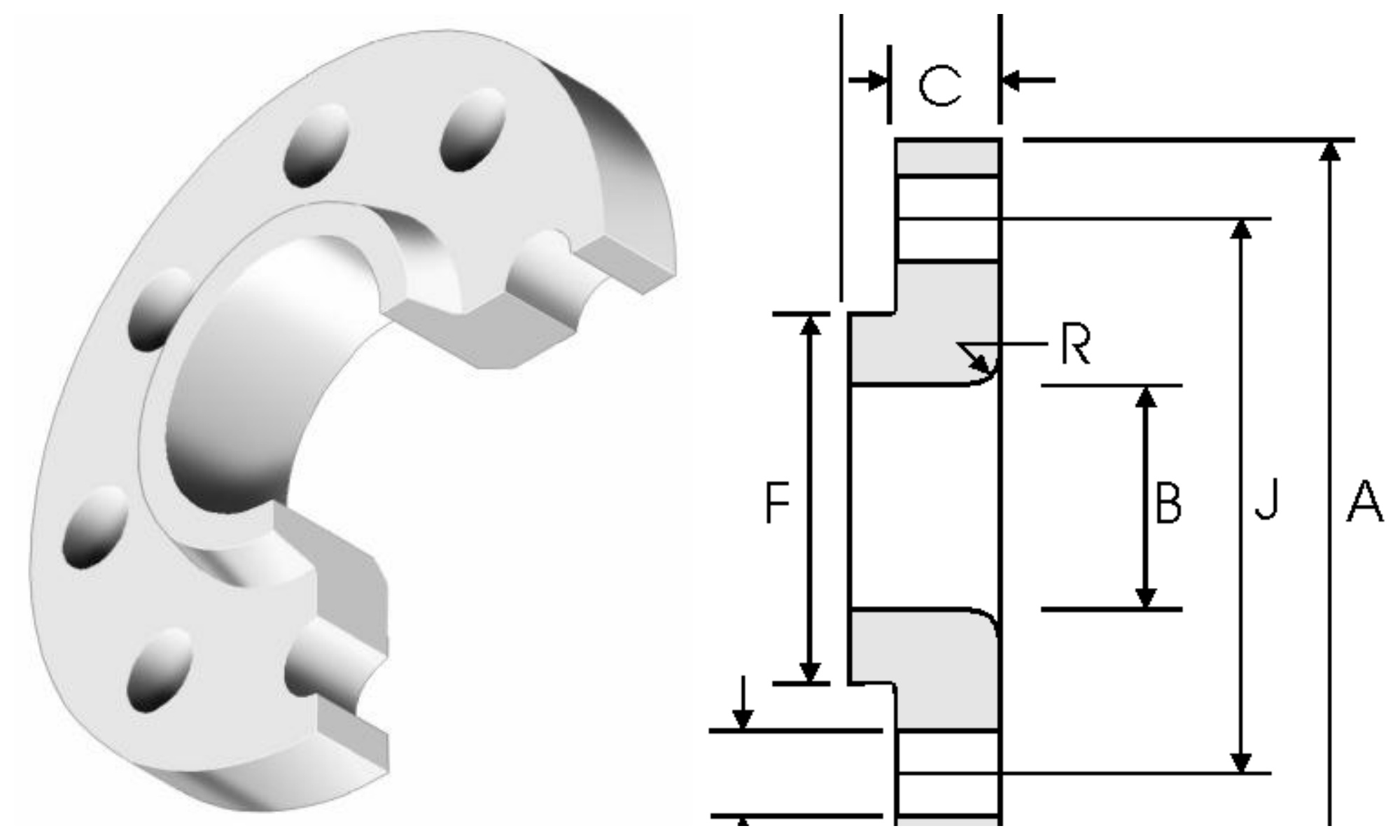

Features: It has a conical neck with a flow aperture at the center that matches the inner diameter of the pipeline. It is connected to the pipeline by welding the neck to the pipeline port.

Purpose: Suitable for industrial pipeline systems with high temperature, high pressure, severe circulation, or large temperature fluctuations. The conical neck design enhances the firmness of the flange and pipeline connection, and its weld strength is high, which can effectively alleviate stress concentration.

Class150 Butt Weld Flange Dimension

| Nominal Pipe Size | A | B | C | D | E | F | G | H | I | J | Weight | |

| inch | mm | mm | mm | mm | mm | mm | mm | mm | Holes | mm | mm | kg / piece |

| 1/2 | 21.30 | 88.90 | 15.70 | 11.20 | 47.80 | 21.30 | 30.20 | 35.00 | 4 | 15.70 | 60.45 | 0.48 |

| 3/4 | 26.70 | 98.60 | 20.80 | 12.70 | 52.30 | 26.70 | 38.10 | 42.90 | 4 | 15.70 | 69.85 | 0.71 |

| 1 | 33.40 | 108.0 | 26.70 | 14.20 | 55.60 | 33.50 | 49.30 | 50.80 | 4 | 15.70 | 79.25 | 1.01 |

| 11/4 | 42.20 | 117.3 | 35.10 | 15.70 | 57.15 | 42.20 | 58.70 | 63.50 | 4 | 15.70 | 88.90 | 1.33 |

| 11/2 | 48.30 | 127.0 | 40.90 | 17.50 | 62.00 | 48.30 | 65.00 | 73.15 | 4 | 15.70 | 98.60 | 1.72 |

| 2 | 60.30 | 152.4 | 52.60 | 19.10 | 63.50 | 60.45 | 77.70 | 91.90 | 4 | 19.10 | 120.7 | 2.58 |

| 21/2 | 73.00 | 177.8 | 62.70 | 22.40 | 69.85 | 73. 15 | 90.4 | 104.6 | 4 | 19.10 | 139.7 | 4.11 |

| 3 | 88.90 | 190.5 | 78.00 | 23.90 | 69.85 | 88.90 | 108.0 | 127.0 | 4 | 19.10 | 152.4 | 4.92 |

| 31/2 | 101.6 | 215.9 | 90.20 | 23.90 | 71.40 | 101.6 | 122.2 | 139.7 | 8 | 19.10 | 177.8 | 6.08 |

| 4 | 114.3 | 228.6 | 102.40 | 23.90 | 76.20 | 114.3 | 134.9 | 157.2 | 8 | 19.10 | 190.5 | 6.84 |

| 5 | 141.3 | 254.0 | 128.3 | 23.90 | 88.90 | 141.2 | 163.6 | 185.7 | 8 | 22.40 | 215.9 | 8.56 |

| 6 | 168.3 | 279.4 | 154.2 | 25.40 | 88.90 | 168.4 | 192.0 | 215.9 | 8 | 22.40 | 241.3 | 10.6 |

| 8 | 219.1 | 342.9 | 202.7 | 28.40 | 101.6 | 219.2 | 246.1 | 269.7 | 8 | 22.40 | 298.5 | 17.6 |

| 10 | 273.0 | 406.4 | 254.5 | 30.20 | 101.6 | 273.0 | 304.8 | 323.8 | 12 | 25.40 | 362.0 | 24.0 |

| 12 | 323.8 | 482.6 | 304.8 | 31.75 | 114.3 | 323.8 | 365.3 | 381.0 | 12 | 25.40 | 431.8 | 36.5 |

| 14 | 355.6 | 533.4 | To be specified by the Purchaser | 35.10 | 127.0 | 355.6 | 400.1 | 412.7 | 12 | 28.40 | 476.3 | 48.4 |

| 16 | 406.4 | 596.9 | 36.60 | 127.0 | 406.4 | 475.2 | 469.9 | 16 | 28.40 | 539.8 | 60.6 | |

| 18 | 457.2 | 635.0 | 39.60 | 139.7 | 457.2 | 505.0 | 533.4 | 16 | 31.75 | 577.9 | 68.3 | |

| 20 | 508.0 | 698.5 | 42.90 | 144.5 | 508.0 | 558.8 | 584.2 | 20 | 31.75 | 635.0 | 84.5 | |

| 24 | 609.6 | 812.8 | 47.80 | 152.4 | 609.6 | 663.4 | 692.1 | 20 | 35.10 | 749.3 | 115 | |

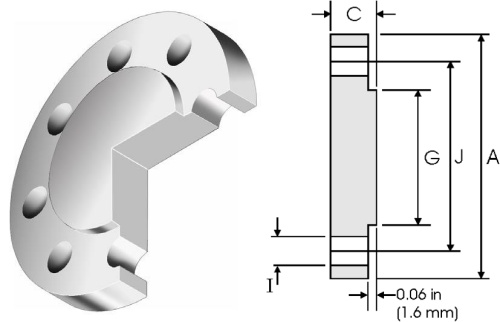

Features: Compared with butt welded flanges, it lacks a conical neck design in appearance, making its structure simpler and reducing costs.

Usage: Commonly used in low-pressure, non critical applications, with lower installation costs, but weaker fatigue resistance than welded flanges.

Dimension of Class600 Slip On Flange

| Nominal Pipe Size | A | B | C | D | F | G | H | I | J | Weight | |

| inch | mm | mm | mm | mm | mm | mm | mm | Holes | mm | mm | kg / piece |

| 1/2 | 21.3 | 95.3 | 22.4 | 14.2 | 22.4 | 38.1 | 35.1 | 4 | 15.7 | 66.55 | 0.74 |

| 3/4 | 26.7 | 117.3 | 27.7 | 15.7 | 25.4 | 47.8 | 42.9 | 4 | 19.1 | 82.6 | 1.27 |

| 1 | 33.4 | 124 | 34.5 | 17.5 | 26.9 | 53.8 | 50.8 | 4 | 19.1 | 88.9 | 1.52 |

| 11/4 | 42.2 | 133.4 | 43.2 | 20.6 | 28.4 | 63.5 | 63.5 | 4 | 19.1 | 98.6 | 2.03 |

| 11/2 | 48.3 | 155.4 | 49.5 | 22.4 | 31.75 | 69.85 | 73.15 | 4 | 22.4 | 114.3 | 2.96 |

| 2 | 60.3 | 165.1 | 62 | 25.4 | 36.6 | 84.1 | 91.9 | 8 | 19.1 | 127 | 3.62 |

| 21/2 | 73 | 190.5 | 74.7 | 28.4 | 41.1 | 100.1 | 104.6 | 8 | 22.4 | 149.4 | 5.28 |

| 3 | 88.9 | 209.6 | 90.7 | 31.75 | 46 | 117.3 | 127 | 8 | 22.4 | 168.1 | 7.00 |

| 31/2 | 101.6 | 228.6 | 103.4 | 35.1 | 49.3 | 133.4 | 139.7 | 8 | 25.4 | 184.2 | 8.84 |

| 4 | 114.3 | 273.1 | 116.1 | 38.1 | 53.8 | 152.4 | 157.2 | 8 | 25.4 | 215.9 | 14.5 |

| 5 | 141.3 | 330.2 | 143.8 | 44.5 | 60.45 | 189 | 185.7 | 8 | 28.4 | 266.7 | 24.4 |

| 6 | 168.3 | 355.6 | 170.7 | 47.8 | 66.55 | 222.3 | 215.9 | 12 | 28.4 | 292.1 | 28.7 |

| 8 | 219. 1 | 419.1 | 221.5 | 55.6 | 76.2 | 273.1 | 269.7 | 12 | 31.75 | 349.3 | 43.4 |

| 10 | 273 | 508 | 276.3 | 63.5 | 85.9 | 342.9 | 323.9 | 16 | 35.1 | 431.8 | 70.3 |

| 12 | 323.8 | 558.8 | 327.1 | 66.55 | 91.9 | 400.1 | 381 | 20 | 35.1 | 489 | 84.2 |

| 14 | 355.6 | 603.3 | 359.1 | 69.85 | 93.7 | 431.8 | 412.8 | 20 | 38.1 | 527.1 | 98.7 |

| 16 | 406.4 | 685.8 | 410.5 | 76.2 | 106.4 | 495.3 | 469.9 | 20 | 41.1 | 603.3 | 142 |

| 18 | 457.2 | 743 | 461.8 | 82.6 | 117.3 | 546.1 | 533.4 | 20 | 44.5 | 654.1 | 173 |

| 20 | 508 | 812.8 | 513.1 | 88.9 | 127 | 609.6 | 584.2 | 24 | 44.5 | 723.9 | 220 |

| 24 | 609.6 | 939.8 | 616 | 101.6 | 139.7 | 717.6 | 692.2 | 24 | 50.8 | 838.2 | 312 |

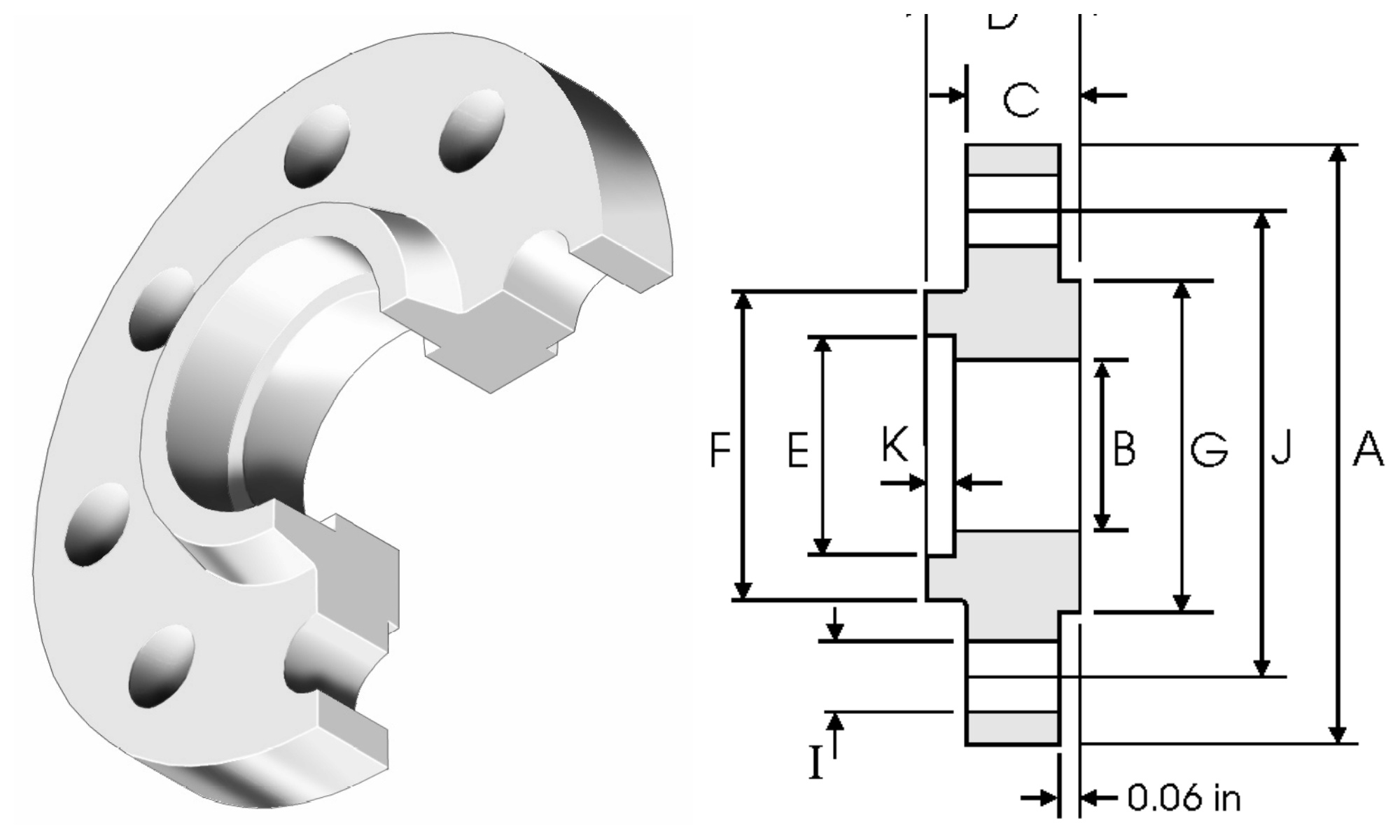

Features: The flange has a socket hole with a diameter slightly larger than the outer diameter of the corresponding pipeline. The pipeline can be inserted into the socket and welded.

Purpose: Suitable for high-pressure pipelines with small diameters (usually NPS 4 and below), installation is more convenient than butt welding flanges, and can avoid residual inside the weld seam.

Dimension of Class300 Socket Weld Flange

| Nominal Pipe Size | A | B | C | D | E | K | F | G | H | I | J | Weight | |

| inch | mm | mm | mm | mm | mm | mm | mm | mm | mm | Holes | mm | mm | kg / piece |

| 1/2 | 21.30 | 95.20 | 15.70 | 14.20 | 22.30 | 22.40 | 9.60 | 38.10 | 35.10 | 4 | 15.70 | 66.55 | 0.66 |

| 3/4 | 26.70 | 117.3 | 20.80 | 15.70 | 25.40 | 27.70 | 11.10 | 47.70 | 42.90 | 4 | 19.10 | 82.50 | 1.15 |

| 1 | 33.40 | 123.9 | 26.70 | 17.50 | 26.90 | 34.50 | 12.70 | 53.80 | 50.80 | 4 | 19.10 | 88.90 | 1.40 |

| 11/4 | 42.20 | 133.3 | 35.10 | 19.00 | 26.90 | 43.20 | 14.20 | 63.50 | 63.50 | 4 | 19.10 | 98.60 | 1.75 |

| 11/2 | 48.30 | 155.4 | 40.90 | 20.60 | 30.20 | 49.50 | 15.70 | 69.85 | 73.15 | 4 | 22.30 | 114.3 | 2.55 |

| 2 | 60.30 | 165.1 | 52.60 | 22.30 | 33.20 | 62.00 | 17.50 | 84.00 | 91.90 | 8 | 19.10 | 127.0 | 2.93 |

| 21/2 | 73.00 | 190.5 | 62.70 | 25.40 | 38.10 | 74.70 | 19.00 | 100.0 | 104.6 | 8 | 22.30 | 149.3 | 4.40 |

| 3 | 88.90 | 209.5 | 78.00 | 28.40 | 42.90 | 90.70 | 20.60 | 117.3 | 127.0 | 8 | 22.30 | 168. 1 | 5.92 |

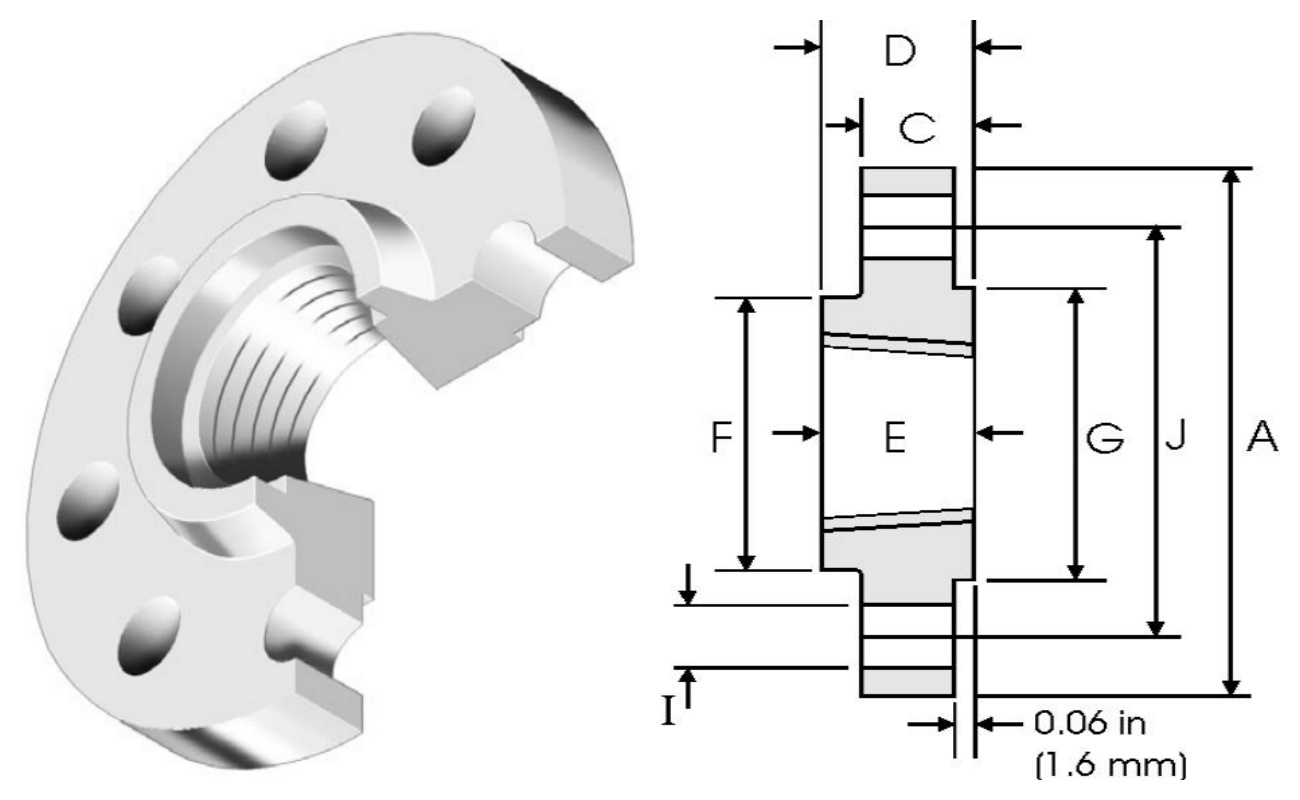

Features: The flange inner hole is threaded and can be directly connected to pipes with external threads, reducing welding processes and making installation and disassembly easier.

Purpose: Mainly used in situations where welding is not allowed or in pipe sections that require frequent disassembly for maintenance.

Class300 Threaded Flange Size and Weight

| Nominal Pipe Size | A | B | C | D | E | F | G | H | I | J | Weight | |

| inch | mm | mm | mm | mm | mm | mm | mm | mm | Holes | mm | mm | kg / piece |

| 1/2 | 21.30 | 95.20 | 23.60 | 14.20 | 22.30 | 15.70 | 38.10 | 35.00 | 4 | 15.70 | 66.55 | 0.64 |

| 3/4 | 26.70 | 117.3 | 29.00 | 15.70 | 25.40 | 15.70 | 47.70 | 42.90 | 4 | 19.00 | 82.50 | 1.12 |

| 1 | 33.40 | 123.9 | 35.80 | 17.50 | 26.90 | 17.50 | 53.80 | 50.80 | 4 | 19.00 | 88.90 | 1.36 |

| 11/4 | 42.20 | 133.3 | 44.40 | 19.00 | 26.90 | 20.60 | 63.50 | 63.50 | 4 | 19.00 | 98.50 | 1.68 |

| 11/2 | 48.30 | 155.4 | 50.50 | 20.60 | 30.20 | 22.30 | 69.85 | 73. 15 | 4 | 22.30 | 114.3 | 2.49 |

| 2 | 60.30 | 165.1 | 63.50 | 22.30 | 33.20 | 28.40 | 84.00 | 91.90 | 8 | 19.00 | 127.0 | 2.87 |

| 21/2 | 73.00 | 190.5 | 76.20 | 25.40 | 38. 10 | 31.70 | 100.0 | 104.6 | 8 | 22.30 | 149.3 | 4.32 |

| 3 | 88.90 | 209.5 | 92.20 | 28.40 | 42.90 | 31.70 | 117.3 | 127.0 | 8 | 22.30 | 168.1 | 5.85 |

| 31/2 | 101.6 | 228.6 | 104.9 | 30.20 | 44.40 | 36.50 | 133.3 | 139.7 | 8 | 22.30 | 184.1 | 7.34 |

| 4 | 114.3 | 254.0 | 117.6 | 31.70 | 47.70 | 36.50 | 146.0 | 157.2 | 8 | 22.30 | 200.1 | 9.61 |

| 5 | 141.3 | 279.4 | 144.5 | 35.00 | 50.80 | 42.90 | 177.8 | 185.7 | 8 | 22.30 | 234.9 | 12.3 |

| 6 | 168.3 | 317.5 | 171.4 | 36.50 | 52.30 | 45.90 | 206.2 | 215.9 | 12 | 22.30 | 269.7 | 15.6 |

| 8 | 219.1 | 381.0 | 222.2 | 41.10 | 61.90 | 50.80 | 260.3 | 269.7 | 12 | 25.40 | 330.2 | 24.2 |

| 10 | 273.0 | 444.5 | 276.3 | 47.70 | 66.55 | 55.60 | 320.5 | 323.9 | 16 | 28.40 | 387.3 | 34.1 |

| 12 | 323.8 | 520.7 | 328.7 | 50.80 | 73. 15 | 60.45 | 374.6 | 381.0 | 16 | 31.70 | 450.8 | 49.8 |

| 14 | 355.6 | 584.2 | 360.4 | 53.80 | 76.20 | 63.50 | 425.4 | 412.7 | 20 | 31.70 | 514.3 | 69.9 |

| 16 | 406.4 | 647.7 | 411.2 | 57.15 | 82.50 | 68.30 | 482.6 | 469.9 | 20 | 35.00 | 571.5 | 88.1 |

| 18 | 457.2 | 711.2 | 462.0 | 60.45 | 88.90 | 69.85 | 533.4 | 533.4 | 24 | 35.00 | 628.6 | 109 |

| 20 | 508.0 | 774.7 | 512.8 | 63.50 | 95.20 | 73.15 | 587.2 | 584.2 | 24 | 35.00 | 685.8 | 134 |

| 24 | 609.6 | 914.4 | 614.4 | 69.85 | 106.4 | 82.50 | 701.5 | 692.2 | 24 | 41.10 | 812.8 | 201 |

Features: Composed of a flanged short section and a loose flange ring, the flange ring can rotate freely.

Purpose: Especially suitable for situations where bolt holes need to be aligned or easy to install and disassemble, such as ship pipelines and frequently maintained pipelines, which can effectively reduce installation difficulty.

Class1500 Lap Joint Flange Dimension and Weight

| Nominal Pipe Size | A | B | C | D | R | F | H | I | J | Weight | ||

| inch | mm | mm | mm | mm | mm | mm | mm | Holes | mm | mm | kg / piece | |

| 1/2 | 21.30 | 120.6 | 22.90 | 22.30 | 31.70 | 3.000 | 38.10 | 4 | 22.30 | 82.50 | 1.71 | |

| 3/4 | 26.70 | 130.0 | 28.20 | 25.40 | 35.00 | 3.000 | 44.40 | 4 | 22.30 | 88.90 | 2.30 | |

| 1 | 33.40 | 149.3 | 35. 10 | 28.40 | 41.10 | 3.000 | 52.30 | 4 | 25.40 | 101.6 | 3.40 | |

| 11/4 | 42.20 | 158.7 | 43.70 | 28.40 | 41.10 | 4.800 | 63.50 | 4 | 25.40 | 111.2 | 3.85 | |

| 11/2 | 48.30 | 177.8 | 50.00 | 31.70 | 44.40 | 6.400 | 69.85 | 4 | 28.40 | 123.9 | 5.28 | |

| 2 | 60.30 | 215.9 | 62.50 | 38.10 | 57.15 | 7.900 | 104.6 | 8 | 25.40 | 165.1 | 9.78 | |

| 21/2 | 73.00 | 244.3 | 75.40 | 41.10 | 63.50 | 7.900 | 123.9 | 8 | 28.40 | 190.5 | 13.6 | |

| 3 | 88.90 | 266.7 | 91.40 | 47.70 | 73.15 | 9.700 | 133.3 | 8 | 31.70 | 203.2 | 17.8 | |

| 4 | 114.3 | 311.1 | 116.8 | 53.80 | 90.40 | 11.20 | 162.0 | 8 | 35.00 | 241.3 | 27.5 | |

| 5 | 141.3 | 374.6 | 114.5 | 73.15 | 104.60 | 11.20 | 196.8 | 8 | 41.10 | 292.1 | 51.5 | |

| 6 | 168.3 | 399.7 | 171.5 | 82.50 | 119. 1 | 12.70 | 228.6 | 12 | 38.10 | 317.5 | 62.0 | |

| 8 | 219. 1 | 482.6 | 222.3 | 91.90 | 142.7 | 12.70 | 292.1 | 12 | 44.40 | 393.7 | 105 | |

| 10 | 273.0 | 584.2 | 277.4 | 107.9 | 177.8 | 12.70 | 368.3 | 12 | 50.80 | 482.6 | 179 | |

| 12 | 323.8 | 673.1 | 328.2 | 123.9 | 218.9 | 12.70 | 450.8 | 16 | 53.80 | 571.5 | 269 | |

| 14 | 355.6 | 749.3 | 360.2 | 133.3 | 241.3 | 12.70 | 495.3 | 16 | 60.45 | 635.0 | 365 | |

| 16 | 406.4 | 825.5 | 411.2 | 146.0 | 260.3 | 12.70 | 552.4 | 16 | 66.55 | 704.8 | 459 | |

| 18 | 457.2 | 914.4 | 462.3 | 162.0 | 276.3 | 12.70 | 596.9 | 16 | 73.15 | 774.7 | 598 | |

| 20 | 508.0 | 984.2 | 514.4 | 177.8 | 292.1 | 12.70 | 641.3 | 16 | 79.25 | 831.8 | 712 | |

| 24 | 609.6 | 1168.4 | 616.0 | 203.2 | 330.2 | 12.70 | 762.0 | 16 | 91.90 | 990.6 | 1090 | |

Characteristic: It is also commonly referred to as a flange cover. Its appearance is in the shape of a solid disk, with no flow hole in the center.

Purpose: Used for the end or branch ports of pipeline systems to achieve closed sealing of pipelines, preventing medium leakage or external impurities from entering the pipes.

Dimension and Weight of Class150 Blind Flange

| Norminal Pipe Size | A | C | G | H | I | J | Weight | |

| inch | mm | mm | mm | mm | Holes | mm | mm | kg / piece |

| 1/2 | 21.3 | 88.9 | 11.2 | 35. 10 | 4 | 15.7 | 60.45 | 0.42 |

| 3/4 | 26.7 | 98.6 | 12.7 | 42.9 | 4 | 15.7 | 69.85 | 0.61 |

| 1 | 33.4 | 108 | 14.2 | 50.8 | 4 | 15.7 | 79.25 | 0.86 |

| 11/4 | 42.2 | 117.3 | 15.7 | 63.5 | 4 | 15.7 | 88.9 | 1.17 |

| 11/2 | 48.3 | 127 | 17.5 | 73. 15 | 4 | 15.7 | 98.6 | 1.53 |

| 2 | 60.3 | 152.4 | 19. 10 | 91.9 | 4 | 19.1 | 120.7 | 2.42 |

| 21/2 | 73.0 | 177.8 | 22.4 | 104.6 | 4 | 19.1 | 139.7 | 3.94 |

| 3 | 88.9 | 190.5 | 23.9 | 127 | 4 | 19.1 | 152.4 | 4.93 |

| 31/2 | 101.6 | 215.9 | 23.9 | 139.7 | 8 | 19.1 | 177.8 | 6.17 |

| 4 | 114.3 | 228.6 | 23.9 | 157.2 | 8 | 19.1 | 190.5 | 7.00 |

| 5 | 141.3 | 254 | 23.9 | 185.7 | 8 | 22.4 | 215.9 | 8.63 |

| 6 | 168.3 | 279.4 | 25.4 | 215.9 | 8 | 22.4 | 241.3 | 11.3 |

| 8 | 219.1 | 342.9 | 28.4 | 269.7 | 8 | 22.4 | 298.5 | 19.6 |

| 10 | 273.0 | 406.4 | 30.2 | 323.9 | 12 | 25.4 | 362 | 28.8 |

| 12 | 323.8 | 482.6 | 31.75 | 381 | 12 | 25.4 | 431.8 | 43.2 |

| 14 | 355.6 | 533.4 | 35. 10 | 412.8 | 12 | 28.4 | 476.3 | 58.1 |

| 16 | 406.4 | 596.9 | 36.6 | 469.9 | 16 | 28.4 | 539.8 | 76.0 |

| 18 | 457.2 | 635 | 39.6 | 533.4 | 16 | 31.75 | 577.9 | 93.7 |

| 20 | 508.0 | 698.5 | 42.9 | 584.2 | 20 | 31.75 | 635 | 122 |

| 24 | 609.6 | 812.8 | 47.8 | 692.2 | 20 | 35.1 | 749.3 | 185 |

ASME B16.5 and ASME B16.47 are production standards issued by the American Society of Mechanical Engineers (ASME) for the dimensions and pressure ratings of forged flanges. There are significant differences between the two in terms of scope of application, flange type, pressure rating, etc.

The full name of ASME B16.47 standard is "Large Diameter Pipe Flanges", which covers large-diameter forged flanges (NPS 26 to NPS 60). This standard is divided into two series: Series A and Series B. Series B flange is derived from API 605 standard, and its size and load-bearing capacity are different from Series A derived from MSS SP-44, meeting the application needs of different regions and industries.

A-series: Originating from MSS SP-44, the outer diameter of the flange and the diameter of the bolt hole center circle are relatively large, resulting in stronger load-bearing capacity and rigidity.

B series: derived from API 605, its structure is relatively compact, with a smaller outer diameter and bolt ring diameter, and a larger number of bolts, making it more lightweight.

Different flange size ranges

The ASME B16.5 standard is mainly applicable to flanges ranging from 1/2 inch to 24 inches.

The ASME B16.47 standard is mainly applicable to large flanges ranging from 26 inches to 60 inches.

Overall, ASME B16.5 and ASME B16.47 do not overlap in their application scope. The former is mainly used for small flanges, while the latter is mainly used for large flanges.

The pressure range varies

The ASME B16.5: Class 150, 300, 400, 600, 900, 1500, 2500, etc.

ASME B16.47

A-series: Class150, 300, 400, 600, 900, etc.

B-series: Class75, 150, 300, 400, 600, 900, etc.

Different types of flanges

The ASME B16.5 standard includes six types of flanges: weld neck flange (WN), slip on flange (SO), socket weld flange (SW), threaded flange (TH), blind flange (BL), and lap joint flange (LAPJ).

The ASME B16.47 standard includes two types of flanges: weld neck flanges (WN) and blind flanges (BL).

ASME B16.5 forged flanges include multiple types of flanges that can meet the design requirements of various industrial piping systems. A thorough understanding of the scope of application of standards, the characteristics and uses of flange types is a key factor in correctly selecting flange products that meet the design requirements of pipeline systems.

Shanghai Zhucheng Pipe Fitting Manufacturing Co., Ltd. has been focusing on the production and sales of forged flanges for many years. With high-quality products and professional services, we have won the trust of customers at home and abroad. Welcome to contact us, and we will provide you with professional services and fast and favorable quotations.