Views: 18 Author: Site Editor Publish Time: 2025-09-18 Origin: Site

ASME B16.5 is a pipeline flange and flange fitting standard developed by the American Society of Mechanical Engineers (ASME), which has high recognition and wide application in the global industrial field. This standard provides strict and detailed regulations on the size, pressure rating, material requirements, connection method, sealing performance, and other aspects of flanges, ensuring that they can operate stably and safely under different working conditions.

From the perspective of pressure rating, the ASME B16.5 stainless steel flange standard covers more than Class 150 to Class 2500, which can meet the usage needs of different pressure environments such as low pressure, medium pressure, and high pressure. In terms of size range, the standard includes flange specifications from 1/2 inch (DN15) to 24 inches (DN600), suitable for various pipeline sizes, providing a unified standard basis for the design and installation of industrial pipeline systems, effectively reducing safety hazards and engineering costs caused by inconsistent standards.

Types | WN Flange、SO Flange、SW Flange、TH Flange、LAPJ Flange、Blind Flange |

Sealing Surface | RF, FF, RTJ |

Size | 1/2" - 60" / DN15 - DN1500 |

Standard | ASME B16.5 ASME B16.47 A/B |

Stainless Steel | ASTM A182 F304/304L/304H, 316/316L, 310S, 317,347,904L |

Duplex Stainless Steel | ASTM A182 F51, F53, F44 |

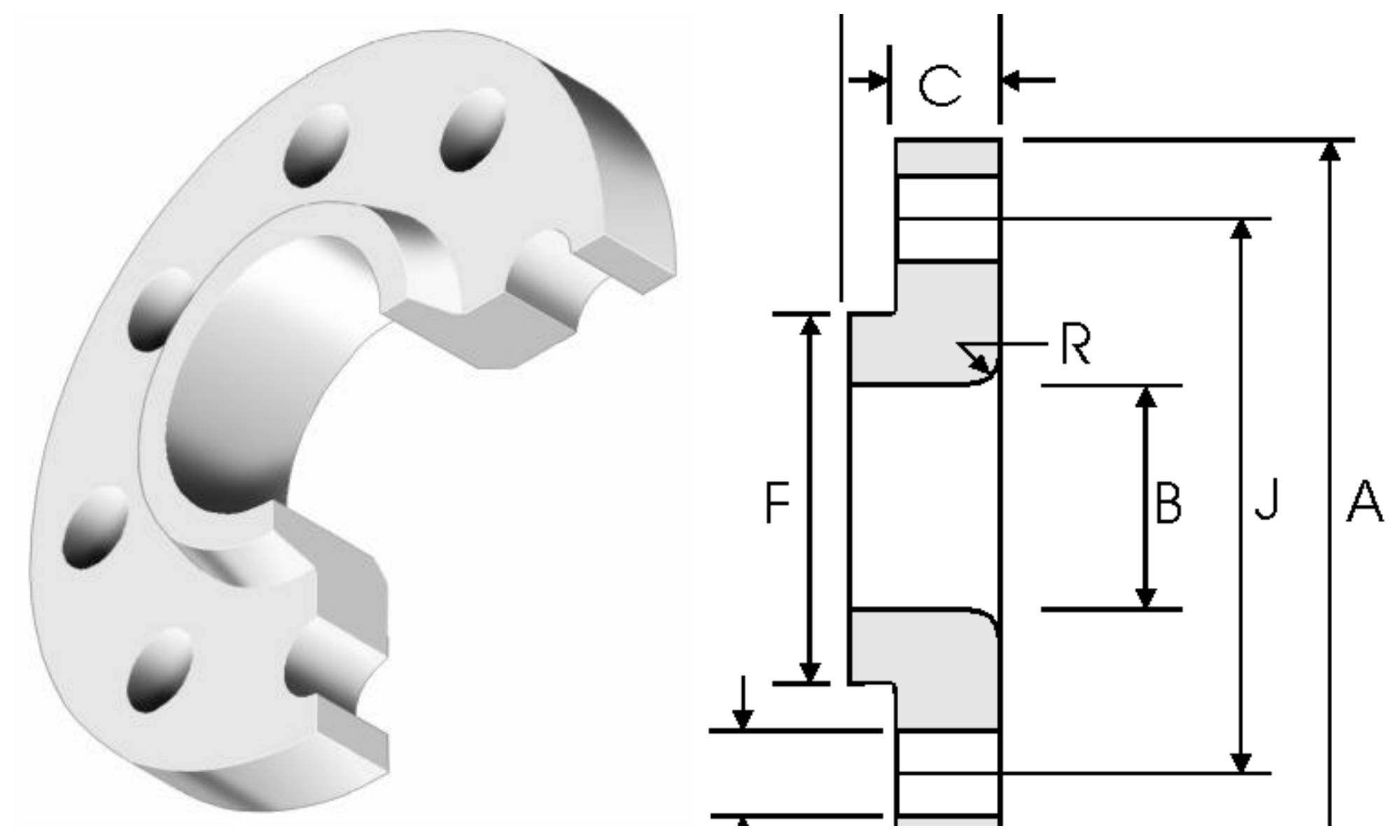

The dimensional parameters of ASME B16.5 stainless steel flange strictly follow the standard regulations, mainly including the following key parts:

Nominal Diameter (DN): ranging from DN15 (1/2 ") to DN600 (24" ), representing the nominal size of the flange adapted pipeline.

Nominal Pressure (Class): covering multiple levels such as Class 150, 300, 600, 900, 1500, 2500, etc. Different pressure levels correspond to different flange thicknesses, bolt quantities, and sizes.

Flange Outer Diameter: It varies depending on the nominal diameter and pressure rating. For example, the outer diameter of DN50 (2 inches) and Class 150 butt welding flanges is 152mm, while the outer diameter of DN50 and Class 300 butt welding flanges is 165mm.

Flange Thickness: The higher the pressure rating, the thicker the flange to ensure sufficient strength to withstand pressure. The thickness of butt welded flanges for DN100 (4 inches) and Class 150 is 19mm, while for Class 300 it is 27mm.

Number and Diameter of Bolt Holes: The number of bolt holes is usually an even number such as 4, 8, 12, etc. The diameter is determined based on the pressure level and nominal diameter to ensure the strength and sealing of the bolt connection. Taking DN150 (6 inches) and Class 150 butt welded flanges as an example, there are 8 bolt holes with a diameter of 18mm.

Neck Size: including parameters such as neck outer diameter and neck thickness. The design of the neck enhances the overall strength of the flange and pipeline after welding. For example, DN200 (8 inches) and Class 300 butt welded flanges have a neck outer diameter of 219mm and a neck thickness of 22mm.

ASME B16.5 stainless steel flange can be divided into six core types based on connection methods, structural characteristics, and applicable working environments: weld neck flanges, slip on flanges, socket weld flanges, threaded flanges, lap joint flanges, and blind flanges. Each category has clear functional positioning and is suitable for different industrial pipeline requirements.

WN flange: The neck of the weld neck flange is relatively long, and it is connected to the pipeline by welding. The welding strength is high, the sealing is good, and it can withstand high pressure and temperature. It is suitable for high pressure, high temperature, and important pipeline systems.

Dimension of Class150 WN Flange

| Nominal Pipe Size | A | B | C | D | E | F | G | H | I | J | Weight | |

| inch | mm | mm | mm | mm | mm | mm | mm | mm | Holes | mm | mm | kg / piece |

| 1/2 | 21.30 | 88.90 | 15.70 | 11.20 | 47.80 | 21.30 | 30.20 | 35.00 | 4 | 15.70 | 60.45 | 0.48 |

| 3/4 | 26.70 | 98.60 | 20.80 | 12.70 | 52.30 | 26.70 | 38.10 | 42.90 | 4 | 15.70 | 69.85 | 0.71 |

| 1 | 33.40 | 108.0 | 26.70 | 14.20 | 55.60 | 33.50 | 49.30 | 50.80 | 4 | 15.70 | 79.25 | 1.01 |

| 11/4 | 42.20 | 117.3 | 35.10 | 15.70 | 57.15 | 42.20 | 58.70 | 63.50 | 4 | 15.70 | 88.90 | 1.33 |

| 11/2 | 48.30 | 127.0 | 40.90 | 17.50 | 62.00 | 48.30 | 65.00 | 73.15 | 4 | 15.70 | 98.60 | 1.72 |

| 2 | 60.30 | 152.4 | 52.60 | 19.10 | 63.50 | 60.45 | 77.70 | 91.90 | 4 | 19.10 | 120.7 | 2.58 |

| 21/2 | 73.00 | 177.8 | 62.70 | 22.40 | 69.85 | 73. 15 | 90.4 | 104.6 | 4 | 19.10 | 139.7 | 4.11 |

| 3 | 88.90 | 190.5 | 78.00 | 23.90 | 69.85 | 88.90 | 108.0 | 127.0 | 4 | 19.10 | 152.4 | 4.92 |

| 31/2 | 101.6 | 215.9 | 90.20 | 23.90 | 71.40 | 101.6 | 122.2 | 139.7 | 8 | 19.10 | 177.8 | 6.08 |

| 4 | 114.3 | 228.6 | 102.40 | 23.90 | 76.20 | 114.3 | 134.9 | 157.2 | 8 | 19.10 | 190.5 | 6.84 |

| 5 | 141.3 | 254.0 | 128.3 | 23.90 | 88.90 | 141.2 | 163.6 | 185.7 | 8 | 22.40 | 215.9 | 8.56 |

| 6 | 168.3 | 279.4 | 154.2 | 25.40 | 88.90 | 168.4 | 192.0 | 215.9 | 8 | 22.40 | 241.3 | 10.6 |

| 8 | 219.1 | 342.9 | 202.7 | 28.40 | 101.6 | 219.2 | 246.1 | 269.7 | 8 | 22.40 | 298.5 | 17.6 |

| 10 | 273.0 | 406.4 | 254.5 | 30.20 | 101.6 | 273.0 | 304.8 | 323.8 | 12 | 25.40 | 362.0 | 24.0 |

| 12 | 323.8 | 482.6 | 304.8 | 31.75 | 114.3 | 323.8 | 365.3 | 381.0 | 12 | 25.40 | 431.8 | 36.5 |

| 14 | 355.6 | 533.4 | To be specified by the Purchaser | 35.10 | 127.0 | 355.6 | 400.1 | 412.7 | 12 | 28.40 | 476.3 | 48.4 |

| 16 | 406.4 | 596.9 | 36.60 | 127.0 | 406.4 | 475.2 | 469.9 | 16 | 28.40 | 539.8 | 60.6 | |

| 18 | 457.2 | 635.0 | 39.60 | 139.7 | 457.2 | 505.0 | 533.4 | 16 | 31.75 | 577.9 | 68.3 | |

| 20 | 508.0 | 698.5 | 42.90 | 144.5 | 508.0 | 558.8 | 584.2 | 20 | 31.75 | 635.0 | 84.5 | |

| 24 | 609.6 | 812.8 | 47.80 | 152.4 | 609.6 | 663.4 | 692.1 | 20 | 35.10 | 749.3 | 115 | |

SO flange:Slip on flanges have a simple structure and low production cost. During installation, only the flange and pipeline need to be corner welded, making them suitable for low-pressure and room temperature pipeline systems.

Class 300 ASME B16.5 SO Flange Dimension

| Nominal Pipe Size | A | B | C | D | F | G | H | I | J | Weight | |

| inch | mm | mm | mm | mm | mm | mm | mm | Holes | mm | mm | kg / piece |

| 1/2 | 21.3 | 95.2 | 22.4 | 14.2 | 22.4 | 38.1 | 35.1 | 4 | 15.7 | 66.55 | 0.64 |

| 3/4 | 26.7 | 27.7 | 15.7 | 25.4 | 47.7 | 42.9 | 4 | 19.1 | 82.5 | 1. 12 | |

| 1 | 33.4 | 123.9 | 34.5 | 17.5 | 26.9 | 53.8 | 50.8 | 4 | 19.1 | 88.9 | 1.36 |

| 11/4 | 42.2 | 133.3 | 43.2 | 19 | 26.9 | 63.5 | 63.5 | 4 | 19.1 | 98.6 | 1.68 |

| 11/2 | 48.3 | 155.4 | 49.5 | 20.6 | 30.2 | 69.85 | 73.15 | 4 | 22.4 | 4.500 114.3 | 2.49 |

| 2 | 60.3 | 165.1 | 62 | 22.3 | 33.2 | 84 | 91.9 | 8 | 19.1 | 127 | 2.87 |

| 21/2 | 73 | 190.5 | 74.7 | 25.4 | 38.1 | 100 | 104.6 | 8 | 22.4 | 149.4 | 4.32 |

| 3 | 88.9 | 209.5 | 90.7 | 28.4 | 42.9 | 117.3 | 127 | 8 | 22.4 | 168.1 | 5.85 |

| 31/2 | 101.6 | 228.6 | 103.4 | 30.2 | 44.4 | 133.3 | 139.7 | 8 | 22.4 | 184.2 | 7.34 |

| 4 | 114.3 | 254 | 116.1 | 31.7 | 47.7 | 146 | 157.2 | 8 | 22.4 | 200.1 | 9.61 |

| 5 | 141.3 | 279.4 | 143.8 | 35 | 50.8 | 177.8 | 185.7 | 8 | 22.4 | 234.9 | 12.3 |

| 6 | 168.3 | 317.5 | 170.7 | 36.5 | 52.3 | 206.2 | 215.9 | 12 | 22.4 | 269.7 | 15.6 |

| 8 | 219. 1 | 381 | 221.5 | 41.1 | 61.9 | 260.3 | 269.7 | 12 | 25.4 | 330.2 | 24.2 |

| 10 | 273 | 444.5 | 276.3 | 47.7 | 66.55 | 320.5 | 323.9 | 16 | 28.4 | 387.3 | 34.1 |

| 12 | 323.8 | 520.7 | 327.1 | 50.8 | 73.15 | 374.6 | 381 | 16 | 31.7 | 450.8 | 49.8 |

| 14 | 355.6 | 584.2 | 359.1 | 53.8 | 76.2 | 425.4 | 412.8 | 20 | 31.7 | 514.4 | 69.9 |

| 16 | 406.4 | 647.7 | 410.5 | 57.15 | 82.5 | 482.6 | 469.9 | 20 | 35 | 571.5 | 88.1 |

| 18 | 457.2 | 711.2 | 461.8 | 60.45 | 88.9 | 533.4 | 533.4 | 24 | 35 | 628.7 | 109 |

| 20 | 508 | 774.7 | 513.1 | 63.5 | 95.2 | 587.2 | 584.2 | 24 | 35 | 685.8 | 134 |

| 24 | 609.6 | 914.4 | 616 | 69.85 | 106.4 | 701.5 | 692.2 | 24 | 41 | 812.8 | 201 |

SW flange: Socket weld flanges range in size from 1/2 inch to 3 inches and are sealed and connected by inserting the pipe into the flange socket. They have good sealing performance and are easy to install, making them suitable for low-pressure, small-diameter pipeline systems.

Dimension of Class 150 Stainless Steel Socket Weld Flange

| Nominal Pipe Size | A | B | C | D | E | K | F | G | H | I | J | Weight | |

| inch | mm | mm | mm | mm | mm | mm | mm | mm | mm | Holes | mm | mm | kg / piece |

| 1/2 | 21.30 | 88.90 | 15.70 | 11.20 | 15.70 | 22.40 | 9.60 | 30.20 | 35.10 | 4 | 15.70 | 60.45 | 0.42 |

| 3/4 | 26.70 | 98.60 | 20.80 | 12.70 | 15.70 | 27.70 | 11.10 | 38.10 | 42.90 | 4 | 15.70 | 69.85 | 0.59 |

| 1 | 33.40 | 108.0 | 26.70 | 14.20 | 17.50 | 34.50 | 12.70 | 49.30 | 50.80 | 4 | 15.70 | 79.25 | 0.81 |

| 11/4 | 42.20 | 117.3 | 35.10 | 15.70 | 20.60 | 43.20 | 14.20 | 58.70 | 63.50 | 4 | 15.70 | 88.90 | 1.07 |

| 11/2 | 48.30 | 127.0 | 40.90 | 17.50 | 22.30 | 49.50 | 15.70 | 65.00 | 73.15 | 4 | 15.70 | 98.60 | 1.36 |

| 2 | 60.30 | 152.4 | 52.60 | 19.10 | 25.40 | 62.00 | 17.50 | 77.70 | 91.90 | 4 | 19.10 | 120.7 | 2.10 |

| 21/2 | 73.00 | 177.8 | 62.70 | 22.40 | 28.40 | 74.70 | 19.00 | 90.40 | 104.60 | 4 | 19.10 | 139.7 | 3.33 |

| 3 | 88.90 | 190.5 | 78.00 | 23.90 | 30.20 | 90.70 | 20.60 | 108.00 | 127.00 | 4 | 19.10 | 152.4 | 3.90 |

TH flange: Threaded flanges are connected to pipelines using threaded connections, without the need for welding. They are easy to install and disassemble and are suitable for pipeline systems that do not allow welding or require frequent disassembly.

Class 600 Threaded Flange size

| Nominal Pipe Size | A | B | C | D | E | F | G | H | I | J | Weight | |

| inch | mm | mm | mm | mm | mm | mm | mm | mm | Holes | mm | mm | kg / piece |

| 1/2 | 21.30 | 95.20 | 23.60 | 14.20 | 22.40 | 15.70 | 38.10 | 35. 10 | 4 | 15.70 | 66.55 | 0.74 |

| 3/4 | 26.70 | 117.3 | 29.00 | 15.70 | 25.40 | 15.70 | 47.80 | 42.90 | 4 | 19. 10 | 82.60 | 1.27 |

| 1 | 33.40 | 124.0 | 35.80 | 17.50 | 26.90 | 17.50 | 53.80 | 50.80 | 4 | 19. 10 | 88.9 | 1.52 |

| 11/4 | 42.20 | 133.4 | 44.50 | 20.60 | 28.40 | 20.60 | 63.50 | 63.50 | 4 | 19. 10 | 98.60 | 2.03 |

| 11/2 | 48.30 | 155.4 | 50.50 | 22.40 | 31.75 | 22.40 | 69.85 | 73. 15 | 4 | 22.40 | 114.3 | 2.96 |

| 2 | 60.30 | 165.1 | 63.50 | 25.40 | 36.60 | 28.40 | 84.10 | 91.90 | 8 | 19. 10 | 127.0 | 3.62 |

| 21/2 | 73.00 | 190.5 | 76.20 | 28.40 | 41.10 | 31.75 | 400. 1 | 104.6 | 8 | 22.40 | 149.4 | 5.28 |

| 3 | 88.90 | 209.6 | 92.20 | 31.75 | 46.00 | 35. 10 | 117.3 | 127.0 | 8 | 22.40 | 168.1 | 7.00 |

| 31/2 | 101.6 | 228.6 | 104.9 | 35.10 | 49.30 | 39.60 | 133.4 | 139.7 | 8 | 25.40 | 184.2 | 8.84 |

| 4 | 114.3 | 273.1 | 117.6 | 38.10 | 53.80 | 41. 10 | 152.4 | 157.2 | 8 | 25.40 | 215.9 | 14.5 |

| 5 | 141.3 | 330.2 | 144.5 | 44.50 | 60.45 | 47.80 | 189.0 | 185.7 | 8 | 28.40 | 266.7 | 24.4 |

| 6 | 168.3 | 355.6 | 171.5 | 47.80 | 66.55 | 50.80 | 222.3 | 215.9 | 12 | 28.40 | 292.1 | 28.7 |

| 8 | 219.1 | 419.1 | 222.3 | 55.60 | 76.20 | 57. 15 | 273. 1 | 269.7 | 12 | 31.75 | 349.3 | 43.4 |

| 10 | 273.0 | 508.0 | 276.4 | 63.50 | 85.90 | 65.00 | 342.9 | 323.9 | 16 | 35. 10 | 431.8 | 70.3 |

| 12 | 323.8 | 558.8 | 328.7 | 66.55 | 91.90 | 69.85 | 400. 1 | 381.0 | 20 | 35. 10 | 489.0 | 84.2 |

| 14 | 355.6 | 603.3 | 360.4 | 69.85 | 93.70 | 73. 15 | 431.8 | 412.8 | 20 | 38. 10 | 527.1 | 98.7 |

| 16 | 406.4 | 685.8 | 411.2 | 76.20 | 106.4 | 77.70 | 495.3 | 469.9 | 20 | 41. 10 | 603.3 | 142 |

| 18 | 457.2 | 743.0 | 462.0 | 82.60 | 117.3 | 79.25 | 546. 1 | 533.4 | 20 | 44.50 | 654.1 | 173 |

| 20 | 508.0 | 812.8 | 512.8 | 88.90 | 127.0 | 82.60 | 609.6 | 584.2 | 24 | 44.50 | 723.9 | 220 |

| 24 | 609.6 | 939.8 | 614.4 | 101.6 | 139.7 | 91.90 | 717.6 | 692.2 | 24 | 50.80 | 838.2 | 312 |

LAPJ flange: The flange of the lap joint flange can move freely on the pipeline. When installing, only the loose flange needs to be used in conjunction with the flanged short joint to install it on the pipeline system. It is suitable for pipeline systems in corrosive media, low or high temperature environments, and situations where pipeline displacement needs to be compensated.

Class 900 LAPJ Flange Dimension

| Nominal Pipe Size | A | B | C | D | R | F | H | I | J | Weight | ||

| inch | mm | mm | mm | mm | mm | mm | mm | Holes | mm | mm | kg / piece | |

| 1/2 | 21.30 | 120.6 | 22.90 | 22.30 | 31.70 | 3.000 | 38.10 | 4 | 22.30 | 82.5 | 1.71 | |

| 3/4 | 26.70 | 130.0 | 28.20 | 25.40 | 35.00 | 3.000 | 44.40 | 4 | 22.30 | 88.90 | 2.30 | |

| 1 | 33.40 | 149.3 | 35.10 | 28.40 | 41.10 | 3.000 | 52.30 | 4 | 25.40 | 101.6 | 3.40 | |

| 11/4 | 42.20 | 158.7 | 43.70 | 28.40 | 41.10 | 4.800 | 63.50 | 4 | 25.40 | 111.2 | 3.85 | |

| 11/2 | 48.30 | 177.8 | 50.00 | 31.70 | 44.40 | 6.400 | 69.85 | 4 | 28.40 | 123.9 | 5.28 | |

| 2 | 60.30 | 215.9 | 62.50 | 38.10 | 57.15 | 7.900 | 104.6 | 8 | 25.40 | 165. 1 | 9.78 | |

| 21/2 | 73.00 | 244.3 | 75.40 | 41.10 | 63.50 | 7.900 | 123.9 | 8 | 28.40 | 190.5 | 13.6 | |

| 3 | 88.90 | 241.3 | 91.40 | 38.10 | 53.80 | 9.700 | 127.0 | 8 | 25.40 | 190.5 | 11.3 | |

| 4 | 114.3 | 292.1 | 116.8 | 44.40 | 69.85 | 11.20 | 158.7 | 8 | 31.70 | 234.9 | 19.2 | |

| 5 | 141.3 | 349.2 | 114.5 | 50.80 | 79.25 | 11.20 | 190.5 | 8 | 35.00 | 279.4 | 31.20 | |

| 6 | 168.3 | 381.0 | 171.5 | 55.60 | 85.80 | 12.70 | 234.9 | 12 | 31.70 | 317.5 | 40.50 | |

| 8 | 219.1 | 469.9 | 222.3 | 63.50 | 114.3 | 12.70 | 298.4 | 12 | 38.10 | 393.7 | 71.5 | |

| 10 | 273.0 | 546.1 | 277.4 | 69.85 | 127.0 | 12.70 | 368.3 | 16 | 38.10 | 469.9 | 104 | |

| 12 | 323.8 | 609.6 | 328.2 | 79.25 | 142.7 | 12.70 | 419.1 | 20 | 38.10 | 533.4 | 139 | |

| 14 | 355.6 | 641.3 | 360.2 | 85.80 | 155.4 | 12.70 | 450.8 | 20 | 41.10 | 558.8 | 161 | |

| 16 | 406.4 | 704.8 | 411.2 | 88.90 | 165.1 | 12.70 | 508.0 | 20 | 44.40 | 615.9 | 194 | |

| 18 | 457.2 | 787.4 | 462.3 | 101.6 | 190.5 | 12.70 | 565.1 | 20 | 50.80 | 685.8 | 267 | |

| 20 | 508.0 | 857.2 | 514.4 | 107.9 | 209.5 | 12.70 | 622.3 | 20 | 53.80 | 749.3 | 334 | |

| 24 | 609.6 | 1041.4 | 616.0 | 139.7 | 266.7 | 12.70 | 749.3 | 20 | 66.55 | 901.7 | 618 | |

BL flange: Blind flanges are used to seal the ends of pipelines, serving to isolate, cut off, or facilitate pipeline maintenance. According to usage requirements, they can be divided into plate blind flanges, eight shaped blind flanges, and other types, widely used at the ends or maintenance locations of various pipeline systems.

Class 2500 ASME B16.5 Blind Flange

| Nominal Pipe Size | A | C | G | H | I | J | Weight | |

| inch | mm | mm | mm | mm | Holes | mm | mm | kg / piece |

| 1/2 | 21.3 | 133.4 | 30.2 | 35. 10 | 4 | 22.4 | 88.9 | 2.99 |

| 3/4 | 26.7 | 139.7 | 31.7 | 42.9 | 4 | 22.4 | 95.3 | 3.50 |

| 1 | 33.4 | 158.8 | 35. 10 | 50.8 | 4 | 25.4 | 108 | 4.96 |

| 11/4 | 42.2 | 184.2 | 38. 10 | 63.5 | 4 | 28.4 | 130 | 7.35 |

| 11/2 | 48.3 | 203.2 | 44.5 | 73. 15 | 4 | 31.75 | 146.1 | 10.4 |

| 2 | 60.3 | 235 | 50.8 | 91.9 | 8 | 28.4 | 171.5 | 15.6 |

| 21/2 | 73 | 266.7 | 57. 15 | 104.6 | 8 | 31.75 | 196.9 | 22.6 |

| 3 | 88.9 | 304.8 | 66.55 | 127 | 8 | 35.1 | 228.6 | 34.8 |

| 4 | 114.3 | 355.6 | 76.2 | 157.2 | 8 | 41.1 | 273.1 | 53.9 |

| 5 | 141.3 | 419.1 | 91.9 | 185.7 | 8 | 47.88 | 323.9 | 90.8 |

| 6 | 168.3 | 482.6 | 108 | 215.9 | 8 | 53.8 | 368.3 | 141 |

| 8 | 219.1 | 552.5 | 127 | 269.7 | 12 | 53.8 | 438.2 | 214 |

| 10 | 273 | 673.1 | 165.1 | 323.9 | 12 | 66.55 | 539.8 | 411 |

| 12 | 323.8 | 762 | 184.2 | 381 | 12 | 73.15 | 619.3 | 592 |

In order to determine compliance with this standard, where a fixed effective number is required where the limits, maximum and minimum values are specified, rounding shall be in accordance with the method defined in ASTM Practice E29.

Required tolerances for different flanges and flange fittings elements are as follows:

Center to Contract Surfaces and Center to End Tolerances

(a). Center-to-Contract Surfaces other than Ring Joint

Size | Tolerance |

NPS ≤ 10 | +/- 1.0 mm (+/- 0.03 in.) |

NPS ≤ 12 | +/- 1.5 mm (+/- 0.06 in.) |

(b). Center-to-End (Ring Joint)

Size | Tolerance |

NPS ≤ 10 | +/- 1.0 mm (+/- 0.03 in.) |

NPS ≤ 12 | +/- 1.5 mm (+/- 0.06 in.) |

(c). Center surface-to-Contact surface other than ring joint

Size | Tolerance |

NPS ≤ 10 | ±2.0 mm(±0.06 in.) |

NPS ≥ 12 | ±3.0 mm(±0.12 in.) |

(d). End-to-End

Size | Tolerance |

NPS ≤ 10 | ±2.0 mm(±0.06 in.) |

NPS ≥ 12 | ±3.0 mm(±0.12 in.) |

Tolerances for Flange Facings

For both flange and flanged fittings facings tolerances are as follows:

(a) Inside and outside diameter of large and small tongue and groove and female, ±0.5 mm (±0.02 in.).

(b) Outside diameter,2.0 mm (0.06 in.) raised face, ±1.0 mm (±0.03 in.).

(c) Outside diameter, 7.0 mm (0.25 in.) raised face, ±0.5 mm (±0.02 in.).

(d) Ring joint groove tolerances are shown in Table 5 (Table II-5 of Mandatory Appendix II in ASME B16.5)

(e)Perpendicularity of the face with the bore as below table

Size | Tolerance |

NPS ≤ 5 | 1 deg |

NPS ≥ 6 | 0.5 deg |

Flange thickness tolerances

Size | Tolerance |

NPS ≤ 18 | +3.0, -0.0 mm (+0.12,-0.00 in.) |

NPS ≥ 20 | +5.0, -0.0 mm (+0.19,-0.00 in.) |

The plus tolerance is applicable to bolting bearing surfaces whether as-forged, as-cast, spot-faced, or back-faced.

Welding end flange ends and hubs

Outside Diameter

For welding ends of welding neck flanges nominal outside diameter as follows:

Size | Tolerance |

NPS ≤ 5 | +2.0, -1.0 mm (+0.09,-0.03 in.) |

NPS ≥ 6 | +4.0, -1.0 mm (+0.16,-0.03 in.) |

Inside Diameter

Tolerances for nominal inside diameter of welding ends of weld neck flange and socket weld flange with smaller bore.

(a) For figures 7 (Bevel for wall thickness from 5 mm to 22 mm), figure 8 (greater than 22 mm) and figure 4 (Straight Hub Welding Flange) in ASME B16.5.

Size | Tolerance |

NPS ≤ 10 | ±1.0 mm (±0.03 in.) |

12 ≤ NPS ≤ 18 | ±1.5 mm (±0.06 in.) |

NPS ≥ 20 | +3.0, -1.5 mm (+0.12,-0.06 in.) |

For figure 9 (Inside Contour for Use With Rectangular Backing Ring)

Size | Tolerance |

NPS ≤ 10 | +0.0, -1.0 mm (+0.0,-0.03 in.) |

NPS ≥ 12 | +0.0, -1.5 mm (+0.0,-0.06 in.) |

Backing ring contact surface

Size | Tolerance |

2 ≤ NPS ≤ 24 | +0.25, -0.0 mm (+0.01,-0.0 in.) |

Length through hub on welding neck flanges

Size | Tolerance |

NPS ≤ 4 | ±1.5mm (±0.06 in.) |

5 ≤ NPS ≤ 10 | +1.5, -3.0 mm (+0.06,-0.12 in.) |

NPS ≥ 12 | +3.0, -5 mm (+0.12,-0.18 in.) |

Flange Bore Diameter

Lapped and Slip-On Flange Bores

Size | Tolerance |

NPS ≤ 10 | +1.0, -0.0 mm (+0.03,-0.0 in.) |

NPS ≥ 12 | +1.5, -0.0 mm (+0.06,-0.0 in.) |

Counter Bores, Threaded Flanges

Size | Tolerance |

NPS ≤ 10 | +1.0, -0.0 mm (+0.03,-0.0 in.) |

NPS ≥ 12 | +1.5, -0.0 mm (+0.06,-0.0 in.) |

Counter Bores, Socket Welding Flanges

Size | Tolerance |

1/2 ≤ NPS ≤ 3 | ±0.25 mm (±0.010 in.) |

Chemical Composition

| CHEMICAL | LIMITS | C | Mn | P | S | Si | Ni | Cr | Mo | N |

| ASTM A182 F304 | MIN | 8.0 | 18.0 | |||||||

| MAX | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 11.0 | 20.0 | 0.10 |

Mechanical Properties

| MATERIAL | T.S (MPA) | Y.S (MPA) | EL % | R/A % |

| ASTM A182 F304 | 515 min | 205 min | 30 min | 50 min |

Advantages: F304 stainless steel flange has good corrosion resistance and can resist corrosion from atmospheric, water, weak acid and alkali media; Good processing performance, easy to press, bend, weld and other processing operations; High toughness, able to maintain good mechanical properties even in low temperature environments.

Application: Widely used in industries such as food processing, pharmaceuticals, chemicals, water supply and drainage, suitable for contact with media with low corrosiveness and occasions with high hygiene requirements.

Chemical Composition

| CHEMICAL | LIMITS | C | Mn | P | S | Si | Ni | Cr | Mo | N |

| ASTM A182 F316 | MIN | 10.0 | 16.0 | 2.00 | ||||||

| MAX | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 14.0 | 18.0 | 3.00 | 0.01 |

Mechanical Properties

| MATERIAL | T.S (MPA) | Y.S (MPA) | EL % | R/A % |

| ASTM A182 F316 | 515 min | 205 min | 30 min | 50 min |

Advantages: Adding molybdenum element on the basis of 304 stainless steel, it has stronger corrosion resistance, especially able to resist the erosion of strong corrosive media such as seawater, hydrochloric acid, sulfuric acid, etc; It has good high temperature resistance and can be used for a long time in higher temperature environments.

Application: Mainly used in industries such as marine engineering, petrochemicals, printing and dyeing, papermaking, as well as pipeline systems for transporting highly corrosive media, such as seawater desalination equipment pipelines, chemical reactor connection pipelines, etc.

Chemical Composition

| CHEMICAL | LIMITS | C | Mn | P | S | Si | Ni | Cr | Mo | N | Ti |

| ASTM A182 F321 | MIN | 9.00 | 17.00 | 5(C+N) | |||||||

| MAX | 0.08 | 2.00 | 0.05 | 0.03 | 1.00 | 12.00 | 19.00 | 0.10 | 0.70 |

Mechanical Properties

| MATERIAL | T.S (MPA) | Y.S (MPA) | EL % | R/A % |

| ASTM A182 F321 | 515 min | 205 min | 30 min | 50 min |

Advantages: By adding titanium element to stabilize carbon element, it effectively prevents the combination of carbon and chromium to form chromium carbide in high temperature environment, thereby avoiding intergranular corrosion; Excellent high temperature resistance and can be used for a long time in high temperature environments of 600-800 ℃.

Application: Mainly used for pipeline systems under high temperature conditions, such as heating furnace pipelines in petroleum refining and steam pipelines in power plant boilers.

Chemical Composition

| CHEMICAL | LIMITS | C | Mn | P | S | Si | Ni | Cr | Mo | N |

| ASTM A182 F51 | MIN | 4.50 | 21.00 | 2.50 | 0.08 | |||||

| MAX | 0.03 | 2.00 | 0.030 | 0.020 | 1.00 | 6.50 | 23.00 | 3.50 | 0.20 |

Mechanical Properties

| MATERIAL | T.S (MPA) | Y.S (MPA) | EL % | R/A % |

| ASTM A182 F51 | 620 min | 450 min | 35 min | 45 min |

Advantages: The duplex stainless steel flange combines the corrosion resistance of austenitic stainless steel with the high strength of ferritic stainless steel, with a yield strength more than twice that of ordinary austenitic stainless steel; Excellent resistance to stress corrosion cracking and corrosion in chloride media; Good welding performance, no complex heat treatment is required after welding to maintain good performance.

Application: Suitable for harsh working conditions such as oil and gas extraction and transportation, chemical acid and alkali storage tank connection, seawater cooling system, etc., especially suitable for pipeline systems that require both high strength and chloride corrosion resistance, such as offshore platform oil pipelines and chemical park acid and alkali transportation pipelines.

Chemical Composition

| CHEMICAL | LIMITS | C | Mn | P | S | Si | Ni | Cr | Mo | N | Cu |

| ASTM A182 F53 | MIN | 6.00 | 24.00 | 3.00 | 0.24 | ||||||

| MAX | 0.03 | 1.20 | 0.035 | 0.020 | 0.80 | 8.00 | 26.00 | 5.00 | 0.32 | 0.5 |

Mechanical Properties

| MATERIAL | T.S (MPA) | Y.S (MPA) | EL % | R/A % |

| ASTM A182 F53 | 800 min | 550 min | 25 min | 15 min |

Advantages: Based on F51, the chromium, molybdenum, and nitrogen content have been increased, resulting in better corrosion resistance and strength, and the ability to resist strong corrosive media such as sulfuric acid, hydrochloric acid, and organic acids; Improved high temperature resistance, can be used for a long time under working conditions below 300 ℃, and has good resistance to pitting and crevice corrosion.

Application: Mainly used for pipeline systems in extremely corrosive environments, such as wet metallurgy, chemical heavy corrosion reaction kettle connections, high concentration saltwater treatment equipment pipelines, deep-sea oil and gas extraction pipelines, etc., especially suitable for working conditions where strong corrosion and high pressure coexist.

ASME B16.5 stainless steel flange play an important role in the global industrial field with their strict standard specifications, diverse type selection, accurate dimensional parameters, and high-quality material properties, becoming an important guarantee for the safe and reliable operation of various pipeline systems. Whether in high-pressure and high-temperature petrochemical facilities, extremely corrosive deep-sea oil and gas extraction, or in the food and pharmaceutical industry with strict hygiene requirements, ASME B16.5 stainless steel flanges can be seen, providing strong support for the stable operation of industrial production.