Views: 274 Author: Site Editor Publish Time: 2025-03-18 Origin: Site

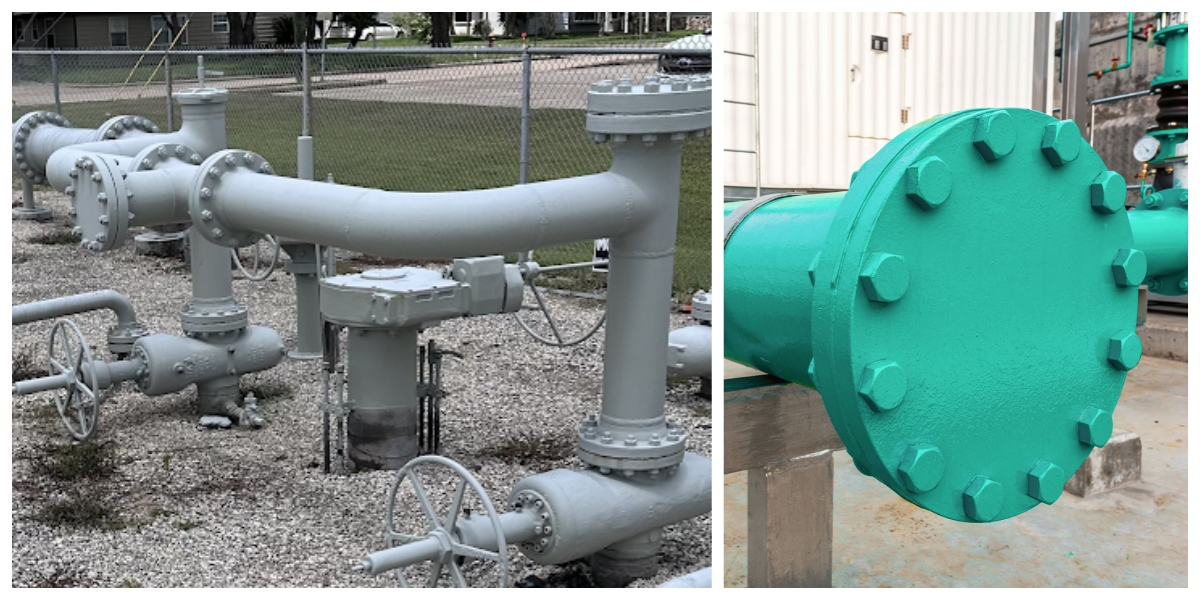

The blind flange, also known as a blind plate, or a blank flange, is a solid flange with no opening in the center. It has the function of sealing the end of the pipe and helps in cleaning debris out of the pipe during maintenance. The blind flange, like a normal flange, has mounting holes around its perimeter and is secured with bolts, enabling quick and easy installation and removal when needed. By using our blind flanges, you can greatly improve production efficiency, minimize costs, and guarantee the stable and secure operation of your pipelines.

As an experienced blind flange manufacturer, we produce various types of blind flanges, including super duplex stainless steel, duplex stainless steel, alloy steel, stainless steel, and carbon steel. The sealing surfaces of our blind flanges are available in two main types: raised face (RF) and flat face (FF). Our blind flanges offer the advantages of high density, excellent pressure resistance, and long service life. Our blind flanges are manufactured according to DIN, ASTM, GOST, GB, JIS, and ANSI standards, and can be customized with various sizes, materials, and sealing types. Feel free to reach out.

Our blind flanges are widely used in industries such as oil, chemical, metallurgy, power generation, and papermaking. In the actual situation, our blind flanges are often used to add new pipelines to existing systems or as temporary closures when installing new valves. Blind flanges have no openings for fluid passage and are installed between two open flanges. During installation, it is crucial to ensure a tight fit against the flange's sealing surface to achieve an effective seal. Specifically, the blind flange should be placed between the flanges and tightly secured using bolts. Notably, there are some factors to consider when choosing the installation position for the blind flange, including ease of operation, safety, and pipeline layout, to ensure efficient installation, removal, and maintenance.

Installing a blind flange is a straightforward process. First, ensure the pipe ends are clean and smooth, free of burrs or indentations. Then, thoroughly clean and dry all components before installation to ensure a proper fit and prevent issues such as corrosion or sticking. To guarantee a secure fit and seal during installation, follow the steps outlined below for the blind flange. Let us take a look together.

A. Preparation Work

Before installation, make sure you have the required tools and accessories, including: blind flange (with bolts), sealing gasket, outer sleeves, inner ring spacers, locking nuts; Wrenches, torque wrenches, plastic scrapers, plastic wedges, and hammer; as well as cleaning and auxiliary materials like acetone, spray glue, and powder.

B. Choose the Right Blind Flange

Make sure the size of the stainless steel blind flange matches the pipe flange size. Also, select the appropriate material and standard based on the application and working environment.

C. Separate the Blind Flange and Clean the Sealing Surface

a. Separate the blind flange using plastic wedges and a hammer to avoid surface scratches.

b. Clean the sealing surface with acetone to remove dirt and oil, ensuring an effective seal.

D. Apply Powder (optional)

Apply a small amount of powder to the sealing surface to minimize adhesion problems, allowing for easier removal in the future.

E. Install the Sealing Gasket

a. Inspect the sealing gasket for any damage and replace it if necessary.

b. Secure the gasket with spray adhesive, ensuring that the bolt holes of the gasket align with those of the blind flange to avoid misalignment.

F. Install Outer Sleeves and Inner Ring Spacers

First, install the outer sleeves, then place the inner ring spacers, making sure that all parts are correctly in place.

G. Install and Secure the Blind Flange

a. The two parts of the blind flange should be placed with the front facing upward and the bolt holes aligned.

b. Install the lower locking nut first, then the upper nut, ensuring they fit tightly together.

c. Tighten the bolts using a torque wrench, applying even force in a cross pattern, until the specified torque value is reached to ensure a tight seal and prevent leakage.

H. Final Check

a. Ensure all gaskets are in place without any misalignment.

b. Tighten the bolts to make sure all parts are securely installed.

c. Conduct a seal check, and if necessary, perform a pressure test to confirm no leaks.

A. Limitations of Blind Flanges for Long-Term Sealing

Blind flanges should not be used for long-term sealing, particularly in high-temperature, high-pressure, or highly corrosive environments. In these situations, specialized sealing devices may be necessary.

B. Ensure Tight Fit During Installation

During installation, make sure the blind flange fits tightly against the flange's sealing surface to avoid gaps that could cause leaks.

C. Regular Seal Performance Checks

Regularly check the seal performance of the stainless steel blind flange to ensure it remains effective during maintenance and repair work.

D. Follow Installation Guidelines to Avoid Damage

Follow the installation guidelines carefully to avoid damaging the bolts or distorting the flange by applying excessive force.

E. Once installed, test the seal to make sure there are no leaks.

A. Leakage after Blind Flange Installation

If leakage occurs after installing the blind flange, it may be due to a damaged sealing surface or improper fit. To fix this, replace the sealing surface or reinstall the flange.

B. Difficulty in Removing the Blind Flange

If the blind flange is hard to remove, it may be due to rusty bolts or overly tight connections. The solution is to use specialized tools or apply lubricant to make removal easier.