Views: 40 Author: Site Editor Publish Time: 2025-03-13 Origin: Site

On August 6, we received a new inquiry from a Vietnamese customer, which mainly involved carbon steel butt weld pipe fittings and flanges, such as butt welding stub-end, flanges, elbows, half couplings, end caps, and hex plugs. The specified materials include A105, P245GH, P265GH, A182 F304, A234 WPB, and CS. The specifications cover various pressure ratings, sizes, and standards, including ASME, EN, and ISO. They offer high temperature, corrosion, and high-pressure resistance, making them suitable for use in industries such as oil, chemical, and power, especially in severe environments. After providing the customer with a quote, they were highly satisfied with our competitive pricing and timely delivery, and they subsequently placed an order with us. Below are the details of the order.

No | Description of Goods | Material | Quantity (EA) |

1 | 1" SCR. COUPLING B16.11 GAS RC 6000# | P245GH | 4 |

2 | END CAP OD 274x127 EN 10253-2 | P265GH | 1 |

3 | ELBOW 90 DEG. 48.3X2.6 LR | A234 WPB | 32 |

4 | ELBOW 90 DEG. 48.3X3.68 LR | A234 WPB | 2 |

5 | FLANGE DN40-PN40 EN10921-1 | P245GH | 8 |

6 | FLANGE DN80 B16.5 150# S.O.R.F | A105 | 320 |

7 | FLAT FACE BLIND FLANGE DN 50 - PN16 - EN 1092-1 | P245GH HOT DIP GALVANIZED | 8 |

8 | SCR. HALF COUPLING ASME B16.11 1-1/2" NPT 3000LB | CS | 48 |

9 | HEX PLUG ASME B16.11 1/2" NPT 6000 LB | ASTM A105 ZINC COATED CERT. ASTM A105-16 | 4 |

10 | HEX PLUG ASME B16.11 2" NPT 6000 LB ASTM A105 | CERT. ASTM A105-16 | 4 |

11 | HEX PLUG ASME B16.11 3" NPT 6000 LB ASTM A105 | ZINC COATED CERT. ASTM A105-16 | 4 |

12 | LAPPED FLANGE DN80 ASME B16.5 150LB | A105 | 320 |

13 | LAPPED FLANGE DN100 ASME B16.5 150LB | A105 | 16 |

14 | SCR. BUSHING ASME B16.11 1"X1/2" NPT 6000LB | ASTM A105 ZINC COATED CERT. ASTM A105-16 | 4 |

15 | SCR. HALF COUPL. ASME B16.11 1/2" NPT 3000 LB | ASTM A105 ZINC COATED CERT. ASTM A105-16 | 49 |

16 | SCR. HALF COUPL. ASME B16.11 2" "B" 3000# | A182 F304 EN 10204/3.1B | 4 |

17 | SCR. HALF COUPL. ASME B16.11 3" "B" 3000# | A182 F304 EN 10204/3.1B | 4 |

18 | SCRD CAP ASME B16.11 2" ISO 7/1-RC 3000LB | A105 WROUGHT | 16 |

19 | HEX. PLUG ASME B16.11 1-1/2" NPT 6000LB | CS | 48 |

20 | BUTT WELDING STUB-END DN80 | A105 | 320 |

21 | BUTT WELDING STUB-END DN100 SCH.40 | A105 | 16 |

22 | CAP DN80 ASME B16.9 SCH.STD BW | A234 WPB | 16 |

23 | COUPLING ASME B16.11 1/2" CLASS 3000 NPT-SW | A105 | 16 |

24 | Flange DN50, PN16 SO.RF Uni 2278/29 | A105 | 8 |

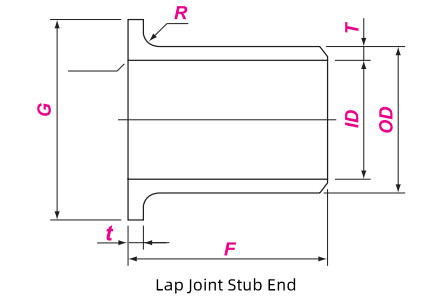

From the purchase order, we can see that one of the main products available for purchase is ASTM A105 Butt Welding Stub End. Let’s take a closer look at the ASTM A105 Butt Welding Stub End. A lap joint stub end is a type of steel butt weld fitting, typically used as a component in loose flanges. Loose flanges are commonly used in situations where the medium has low temperature and pressure but strong corrosiveness.

| DN | NPS | OD | F | R | G | SCH40 WEIGHT | |||||

| Max. | Min. | Long Type | Short Type | A | Bmax | LP (kg) | SP (kg) | ||||

| 15 | 1/2 | 22.8 | 20.5 | 76 | 51 | 3 | 0.8 | 35 | 0.12 | 0.09 | |

| 20 | 3/4 | 28.1 | 25.9 | 76 | 51 | 3 | 0.8 | 43 | 0.16 | 0.12 | |

| 25 | 1 | 35.0 | 32.6 | 102 | 51 | 3 | 0.8 | 51 | 0.32 | 0.18 | |

| 32 | 11/4 | 43.6 | 41.4 | 102 | 51 | 5 | 0.8 | 64 | 0.43 | 0.25 | |

| 40 | 11/2 | 49.9 | 47.5 | 102 | 51 | 6 | 0.8 | 73 | 0.52 | 0.31 | |

| 50 | 2 | 62.4 | 59.5 | 152 | 64 | 8 | 0.8 | 92 | 1.02 | 0.52 | |

| 65 | 21/2 | 75.3 | 72.2 | 152 | 64 | 8 | 0.8 | 105 | 1.60 | 0.81 | |

| 80 | 3 | 91.3 | 88.1 | 152 | 64 | 10 | 0.8 | 127 | 2.11 | 1.10 | |

| 90 | 31/2 | 104.0 | 100.8 | 152 | 76 | 10 | 0.8 | 140 | 2.55 | 1.52 | |

| 100 | 4 | 116.7 | 113.5 | 152 | 76 | 11 | 0.8 | 157 | 3.05 | 1.80 | |

| 125 | 5 | 144.3 | 140.5 | 203 | 76 | 11 | 1.6 | 186 | 5.42 | 2.25 | |

| 150 | 6 | 171.3 | 167.5 | 203 | 89 | 13 | 1.6 | 216 | 7.02 | 3.59 | |

| 200 | 8 | 222.1 | 218.3 | 203 | 102 | 13 | 1.6 | 270 | 10.6 | 5.98 | |

| 250 | 10 | 277.2 | 272.3 | 254 | 127 | 13 | 1.6 | 324 | 18.4 | 10.2 | |

| 300 | 12 | 328.0 | 323.1 | 254 | 152 | 13 | 1.6 | 381 | 22.8 | 14.9 | |

| 350 | 14 | 359.9 | 354.8 | 305 | 152 | 13 | 1.6 | 413 | 28.7 | 15.8 | |

| 400 | 16 | 411.0 | 405.6 | 305 | 152 | 13 | 1.6 | 470 | 33.1 | 18.9 | |

| 450 | 18 | 462.0 | 456.0 | 305 | 152 | 13 | 1.6 | 533 | 38.0 | 22.0 | |

| 500 | 20 | 514.0 | 507.0 | 305 | 152 | 13 | 1.6 | 584 | 42.3 | 24.3 | |

| 550 | 22 | 565.0 | 558.0 | 305 | 152 | 13 | 1.6 | 641 | - | - | |

| 600 | 24 | 616.0 | 609.0 | 305 | 152 | 13 | 1.6 | 692 | 51.2 | 29.6 | |

After receiving the customer's order, we check the product specifications and drawings with the customer and arrange production. After production is completed, we provide customers with inspection photos, details are as follows.