Size Range: 1/2" - 80" / DN15 - 2000

Thickness Schedule: SCH 10 - SCH 160, XXS

Standard: ANSI / ASME B16.9 / MSS SP 43

Size Range: 1/2" - 80" / DN15 - 2000

Thickness Schedule: SCH 10 - SCH 160, XXS

Standard: ANSI / ASME B16.9 / MSS SP 43

Size Range: 1/2" - 48" / DN15 - 1200

Thickness Schedule: SCH 10 - SCH 160, XXS

Standard: ANSI / ASME B16.9

We are a manufacturer, supplier and exporter of ASME B16.9 butt weld equal and reducing tee in China.

ANSI / ASME B16.9 steel pipe tee dimensions and weight chart is free for you.

Shape Type: Equal and Reducing

Size Range: 1/2" - 80" / DN15 - 2000

Thickness Schedule: SCH 10 - SCH 160, XXS

Standard: ANSI / ASME B16.9

Type: Long Pattern (LP) and Short Pattern (SP)

Size Range: 1/2” - 24” / DN15 - 600

Thickness Schedule: SCH 10 - SCH 160, XXS

Size Range: 3/4" - 60" / DN20 - 1500

Thickness Schedule: SCH 10 - SCH 160, XXS

Standard: ANSI / ASME B16.9 / MSS SP 43

Size Range: 3/4" - 60" / DN20 - 1500

Thickness Schedule: SCH 10 - SCH 160, XXS

Standard: ANSI / ASME B16.9 & MSS SP-43

Size Range: 1/2" - 48" / DN15 - 1200

Thickness Schedule: SCH 10 - SCH 160, XXS

Standard: ANSI / ASME B16.9

Type: 90 Degree and 45 Degree

Shape: Straight and Reducing Elbow

Size: 1/8” – 4” / DN6 - DN100

Shape: Equal and Reducing Tee

Size: 1/8"- 4" / DN6 - DN100

Pressure: Class 3000LBS, 6000Lbs, 9000lbs.

Standard: ASME B16.11, BS3799

Shape: Equal Cross Tee and Reducing Cross Tee

Size Range: 1/8” – 4” / DN6 - DN100

Pressure Rating: Class 3000lbs, 6000lbs, 9000lbs.

Standard: GB/T 14383, ASME B16.11, BS3799

Type: Full Coupling and Half Coupling

Shape: Straight Coupling and Reducing Coupling

Size Range: 1/8” – 4” / DN6 - DN100

Pressure Rating: Class 3000lbs, 6000lbs, 9000lbs

Size Range: 1/8” - 3” / DN6 - DN80

Pressure Rating: Class 3000lbs

Standard: MSS SP-83

Type: 90 Degree and 45 Degree Elbow

Shape: Straight and Reducing Elbow

Thread Type: NPT, PT, BSPP, BSPT, PF

Shape: Equal and Reducing Tee

Size Range: 1/8” – 4” / DN6 - DN100

Pressure Rating: Class 2000 lbs, 3000 lbs, 6000 lbs

Shape: Equal and Reducing

Size: 1/8" - 4" / DN6 - DN100

Pressure: Class 2000 lbs, 3000 lbs, 6000 lbs

Type: Full and Half Coupling

Shape: Straight and Reducing Coupling

Thread Type: NPT, PT, BSPP, BSPT, PF

Size Range: 1/8” – 4” / DN6 - DN100

Pressure Rating: Class 3000lbs, 6000lbs

Standard: ASME B16.11, BS3799, EN 10241

Size Range: 1/8” - 3” / DN6 - DN80

Pressure Rating: Class 3000lbs

Standard: MSS SP-83

Shape: Threaded One End (TOE) and Threaded Both End (TBE)

Size : 1/4” - 12” / DN8 - DN300

Thickness : Sch 10 - Sch 160 / XXS

Shape: Concentric and Eccentric

Size: 1/4" - 12" / DN8 - DN300

Thickness: Sch 10 - Sch 160 / XXS

Shape: Equal and Reducing

Thread Type: NPT, PT, BSPP, BSPT, PF

Size Range: 1/8” - 3” / DN6 - DN80

Shape: Hex Head, Square Head and Round Head.

Thread Type: NPT, PT, BSPP, BSPT, PF

Size Range: 1/8" - 4" / DN6 - DN100

Size Range: 1/2" - 80" / DN15 - 2000

Thickness Schedule: SCH 10 - SCH 160, XXS

Standard: ANSI / ASME B16.9 / MSS SP 43

| Availability: | |

|---|---|

| Quantity: | |

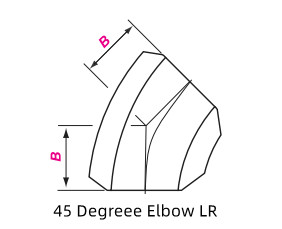

ASME/ANSI B16.9 45 degree elbow have same function and usage with 90 degree elbow, but the dimension and shape is half of it. There is long radius only. The material can be carbon steel, alloy steel and stainless steel. It is quite used in multiple industries such as chemical, petroleum, electronic, fluid power, shipyard, oil and gas.

There are 3 types that socket weld elbow, butt weld elbow and threaded elbow.ASME/ANSI B16.9 45 degree butt weld elbow is common used due to the large range of outside diameter and thickness.

Butt weld Fittings

Buttwelding Fittings are used in a piping system to change direction or function of media, to branch off, reduce pipe size or attach auxiliary equipment. They are availbale in multiple types as elbow, tee, cap, reducer, Lap joint stub end and oelt, that produced in cold and hot forming based on ASTM A403 and ASTM A234 specification. We usually make the end bevelling for welding easily on site.

Before delivery, we will pack the 90° elbow purchased by the customer with length, wall thickness and Angle. Those less than 8 inches will be packed in wooden cases, and those larger than 8 inches will be packed with wooden brackets.

ASME B16.9 Standard covers overall dimensions, tolerances, ratings, testing, and markings for factory-made wrought buttwelding fittings in sizes NPS 1 ∕ 2 through NPS 48 (DN 15 through DN 1200). It covers fittings of any producible wall thickness. This standard does not cover low pressure corrosion resistant buttwelding fittings. See MSS SP-43, Wrought Stainless Steel Butt-Welding Fittings.

Special Fittings

Fittings may be made to special dimensions, sizes.shapes, and tolerances by agreement between the manufacturer and the purchaser.

Codes and Regulations

A fittings sued under ASME Boiler and Pressure Vessel Code (BPVC), the ASME code for pressure piping, or a governmental regulation is subject to any limitation of that code or regulation. It includes any maximum temperature limitation or rule governing the use of material at low temperature.

| Size Range | 1/2"- 80" / DN15 - 2000 |

| Thickness Schedule | SCH 10, 20, 40, STD, XS, 80, 100, 120, 140, 160, XXS |

| Standard | GB/T12459, GB/T13401, HG/T21635/21631, SH3408/3409, ANSI / ASME B16.9, MSS SP 43, JIS B2311/2312/2313, EN10253, DIN2605/2615/2616/2617, EN10253 |

| Carbon Steel Grades | ASTM A234 WPB/WPC, A420 WPL6, A860 WPHY 42 / 46 / 56 / 60 / 65 |

| Alloy Steel Grades | ASTM A234 WP11 / WP12 / WP 5 / WP9 / WP91 / WP92, 15CrMoG, 12Cr1MoVG, 12Cr5Mo, 1Cr5Mo, Cr9Mo, 10CrMo910, 12CrMo4-5 |

| Stainless Steel Grades | ASTM A403 WP304/304L/304H, 316/316L, 310S, 317, 347, 904L |

| Duplex Stainless Steel Grades | ASTM A815 S32205, S31803, 32750, 32760 |

| DN | NPS | OD |  B B | SCH 40 WEIGHT |

| LR | KG | |||

| 15 | 1/2 | 21.3 | 16 | 0.04 |

| 20 | 3/4 | 26.7 | 19 | 0.06 |

| 25 | 1 | 33.4 | 22 | 0.08 |

| 32 | 1-1/4 | 42.2 | 25 | 0.14 |

| 40 | 1-1/2 | 48.3 | 29 | 0.20 |

| 50 | 2 | 60.3 | 35 | 0.36 |

| 65 | 2-1/2 | 73.0 | 44 | 0.71 |

| 80 | 3 | 88.9 | 51 | 1.11 |

| 90 | 3-1/2 | 101.6 | 57 | 1.56 |

| 100 | 4 | 114.3 | 64 | 2.11 |

| 125 | 5 | 141.3 | 79 | 3.56 |

| 150 | 6 | 168.3 | 95 | 5.6 |

| 200 | 8 | 219.1 | 127 | 11.4 |

| 250 | 10 | 273.0 | 159 | 20.0 |

| 300 | 12 | 323.8 | 190 | 31.5 |

| 350 | 14 | 355.6 | 222 | 43.6 |

| 400 | 16 | 406.4 | 254 | 65 |

| 450 | 18 | 457.0 | 286 | 92.5 |

| 500 | 20 | 508.0 | 318 | 121 |

| 550 | 22 | 559.0 | 343 | - |

| 600 | 24 | 610.0 | 381 | 201.5 |

| 650 | 26 | 660.0 | 406 | - |

| 700 | 28 | 711.0 | 438 | - |

| 750 | 30 | 762.0 | 470 | - |

| 800 | 32 | 813.0 | 502 | 361 |

| 850 | 34 | 864.0 | 533 | 409 |

| 900 | 36 | 914.0 | 565 | 499 |

| 950 | 38 | 965.0 | 600 | - |

| 1000 | 40 | 1016.0 | 632 | - |

| 1050 | 42 | 1067.0 | 660 | - |

| 1100 | 44 | 1118.0 | 695 | - |

| 1150 | 46 | 1168.0 | 727 | - |

| 1200 | 48 | 1219.0 | 759 | - |

| 1300 | 52 | 1321.0 | 821 | - |

| 1400 | 56 | 1422.0 | 883 | - |

| 1500 | 60 | 1524.0 | 947 | - |

| 1600 | 64 | 1626.0 | 1010 | - |

| 1700 | 68 | 1727.0 | 1073 | - |

| 1800 | 72 | 1829.0 | 1137 | - |

| 1900 | 76 | 1930.0 | 1199 | - |

| 2000 | 80 | 2032.0 | 1263 | - |

Notes:

1) Besides these, GB/T 10752 SH 3408 SH 3409 HG/T 21635 HG/ T 21631 SY/T 0510 DL/T 695 EN 10253 etc.are also applied.

2) The elbow with NPS over 80 shall be made subject to the sizes agreed by purchaser and manufacturer.

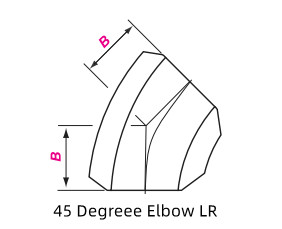

ASME/ANSI B16.9 45 degree elbow have same function and usage with 90 degree elbow, but the dimension and shape is half of it. There is long radius only. The material can be carbon steel, alloy steel and stainless steel. It is quite used in multiple industries such as chemical, petroleum, electronic, fluid power, shipyard, oil and gas.

There are 3 types that socket weld elbow, butt weld elbow and threaded elbow.ASME/ANSI B16.9 45 degree butt weld elbow is common used due to the large range of outside diameter and thickness.

Butt weld Fittings

Buttwelding Fittings are used in a piping system to change direction or function of media, to branch off, reduce pipe size or attach auxiliary equipment. They are availbale in multiple types as elbow, tee, cap, reducer, Lap joint stub end and oelt, that produced in cold and hot forming based on ASTM A403 and ASTM A234 specification. We usually make the end bevelling for welding easily on site.

Before delivery, we will pack the 90° elbow purchased by the customer with length, wall thickness and Angle. Those less than 8 inches will be packed in wooden cases, and those larger than 8 inches will be packed with wooden brackets.

ASME B16.9 Standard covers overall dimensions, tolerances, ratings, testing, and markings for factory-made wrought buttwelding fittings in sizes NPS 1 ∕ 2 through NPS 48 (DN 15 through DN 1200). It covers fittings of any producible wall thickness. This standard does not cover low pressure corrosion resistant buttwelding fittings. See MSS SP-43, Wrought Stainless Steel Butt-Welding Fittings.

Special Fittings

Fittings may be made to special dimensions, sizes.shapes, and tolerances by agreement between the manufacturer and the purchaser.

Codes and Regulations

A fittings sued under ASME Boiler and Pressure Vessel Code (BPVC), the ASME code for pressure piping, or a governmental regulation is subject to any limitation of that code or regulation. It includes any maximum temperature limitation or rule governing the use of material at low temperature.

| Size Range | 1/2"- 80" / DN15 - 2000 |

| Thickness Schedule | SCH 10, 20, 40, STD, XS, 80, 100, 120, 140, 160, XXS |

| Standard | GB/T12459, GB/T13401, HG/T21635/21631, SH3408/3409, ANSI / ASME B16.9, MSS SP 43, JIS B2311/2312/2313, EN10253, DIN2605/2615/2616/2617, EN10253 |

| Carbon Steel Grades | ASTM A234 WPB/WPC, A420 WPL6, A860 WPHY 42 / 46 / 56 / 60 / 65 |

| Alloy Steel Grades | ASTM A234 WP11 / WP12 / WP 5 / WP9 / WP91 / WP92, 15CrMoG, 12Cr1MoVG, 12Cr5Mo, 1Cr5Mo, Cr9Mo, 10CrMo910, 12CrMo4-5 |

| Stainless Steel Grades | ASTM A403 WP304/304L/304H, 316/316L, 310S, 317, 347, 904L |

| Duplex Stainless Steel Grades | ASTM A815 S32205, S31803, 32750, 32760 |

| DN | NPS | OD |  B B | SCH 40 WEIGHT |

| LR | KG | |||

| 15 | 1/2 | 21.3 | 16 | 0.04 |

| 20 | 3/4 | 26.7 | 19 | 0.06 |

| 25 | 1 | 33.4 | 22 | 0.08 |

| 32 | 1-1/4 | 42.2 | 25 | 0.14 |

| 40 | 1-1/2 | 48.3 | 29 | 0.20 |

| 50 | 2 | 60.3 | 35 | 0.36 |

| 65 | 2-1/2 | 73.0 | 44 | 0.71 |

| 80 | 3 | 88.9 | 51 | 1.11 |

| 90 | 3-1/2 | 101.6 | 57 | 1.56 |

| 100 | 4 | 114.3 | 64 | 2.11 |

| 125 | 5 | 141.3 | 79 | 3.56 |

| 150 | 6 | 168.3 | 95 | 5.6 |

| 200 | 8 | 219.1 | 127 | 11.4 |

| 250 | 10 | 273.0 | 159 | 20.0 |

| 300 | 12 | 323.8 | 190 | 31.5 |

| 350 | 14 | 355.6 | 222 | 43.6 |

| 400 | 16 | 406.4 | 254 | 65 |

| 450 | 18 | 457.0 | 286 | 92.5 |

| 500 | 20 | 508.0 | 318 | 121 |

| 550 | 22 | 559.0 | 343 | - |

| 600 | 24 | 610.0 | 381 | 201.5 |

| 650 | 26 | 660.0 | 406 | - |

| 700 | 28 | 711.0 | 438 | - |

| 750 | 30 | 762.0 | 470 | - |

| 800 | 32 | 813.0 | 502 | 361 |

| 850 | 34 | 864.0 | 533 | 409 |

| 900 | 36 | 914.0 | 565 | 499 |

| 950 | 38 | 965.0 | 600 | - |

| 1000 | 40 | 1016.0 | 632 | - |

| 1050 | 42 | 1067.0 | 660 | - |

| 1100 | 44 | 1118.0 | 695 | - |

| 1150 | 46 | 1168.0 | 727 | - |

| 1200 | 48 | 1219.0 | 759 | - |

| 1300 | 52 | 1321.0 | 821 | - |

| 1400 | 56 | 1422.0 | 883 | - |

| 1500 | 60 | 1524.0 | 947 | - |

| 1600 | 64 | 1626.0 | 1010 | - |

| 1700 | 68 | 1727.0 | 1073 | - |

| 1800 | 72 | 1829.0 | 1137 | - |

| 1900 | 76 | 1930.0 | 1199 | - |

| 2000 | 80 | 2032.0 | 1263 | - |

Notes:

1) Besides these, GB/T 10752 SH 3408 SH 3409 HG/T 21635 HG/ T 21631 SY/T 0510 DL/T 695 EN 10253 etc.are also applied.

2) The elbow with NPS over 80 shall be made subject to the sizes agreed by purchaser and manufacturer.