Size Range: 1/2" - 80" / DN15 - 2000

Thickness Schedule: SCH 10 - SCH 160, XXS

Standard: ANSI / ASME B16.9 / MSS SP 43

Size Range: 1/2" - 80" / DN15 - 2000

Thickness Schedule: SCH 10 - SCH 160, XXS

Standard: ANSI / ASME B16.9 / MSS SP 43

Size Range: 1/2" - 48" / DN15 - 1200

Thickness Schedule: SCH 10 - SCH 160, XXS

Standard: ANSI / ASME B16.9

We are a manufacturer, supplier and exporter of ASME B16.9 butt weld equal and reducing tee in China.

ANSI / ASME B16.9 steel pipe tee dimensions and weight chart is free for you.

Shape Type: Equal and Reducing

Size Range: 1/2" - 80" / DN15 - 2000

Thickness Schedule: SCH 10 - SCH 160, XXS

Standard: ANSI / ASME B16.9

Type: Long Pattern (LP) and Short Pattern (SP)

Size Range: 1/2” - 24” / DN15 - 600

Thickness Schedule: SCH 10 - SCH 160, XXS

Size Range: 3/4" - 60" / DN20 - 1500

Thickness Schedule: SCH 10 - SCH 160, XXS

Standard: ANSI / ASME B16.9 / MSS SP 43

Size Range: 3/4" - 60" / DN20 - 1500

Thickness Schedule: SCH 10 - SCH 160, XXS

Standard: ANSI / ASME B16.9 & MSS SP-43

Size Range: 1/2" - 48" / DN15 - 1200

Thickness Schedule: SCH 10 - SCH 160, XXS

Standard: ANSI / ASME B16.9

Type: 90 Degree and 45 Degree

Shape: Straight and Reducing Elbow

Size: 1/8” – 4” / DN6 - DN100

Shape: Equal and Reducing Tee

Size: 1/8"- 4" / DN6 - DN100

Pressure: Class 3000LBS, 6000Lbs, 9000lbs.

Standard: ASME B16.11, BS3799

Shape: Equal Cross Tee and Reducing Cross Tee

Size Range: 1/8” – 4” / DN6 - DN100

Pressure Rating: Class 3000lbs, 6000lbs, 9000lbs.

Standard: GB/T 14383, ASME B16.11, BS3799

Type: Full Coupling and Half Coupling

Shape: Straight Coupling and Reducing Coupling

Size Range: 1/8” – 4” / DN6 - DN100

Pressure Rating: Class 3000lbs, 6000lbs, 9000lbs

Size Range: 1/8” - 3” / DN6 - DN80

Pressure Rating: Class 3000lbs

Standard: MSS SP-83

Type: 90 Degree and 45 Degree Elbow

Shape: Straight and Reducing Elbow

Thread Type: NPT, PT, BSPP, BSPT, PF

Shape: Equal and Reducing Tee

Size Range: 1/8” – 4” / DN6 - DN100

Pressure Rating: Class 2000 lbs, 3000 lbs, 6000 lbs

Shape: Equal and Reducing

Size: 1/8" - 4" / DN6 - DN100

Pressure: Class 2000 lbs, 3000 lbs, 6000 lbs

Type: Full and Half Coupling

Shape: Straight and Reducing Coupling

Thread Type: NPT, PT, BSPP, BSPT, PF

Size Range: 1/8” – 4” / DN6 - DN100

Pressure Rating: Class 3000lbs, 6000lbs

Standard: ASME B16.11, BS3799, EN 10241

Size Range: 1/8” - 3” / DN6 - DN80

Pressure Rating: Class 3000lbs

Standard: MSS SP-83

Shape: Threaded One End (TOE) and Threaded Both End (TBE)

Size : 1/4” - 12” / DN8 - DN300

Thickness : Sch 10 - Sch 160 / XXS

Shape: Concentric and Eccentric

Size: 1/4" - 12" / DN8 - DN300

Thickness: Sch 10 - Sch 160 / XXS

Shape: Equal and Reducing

Thread Type: NPT, PT, BSPP, BSPT, PF

Size Range: 1/8” - 3” / DN6 - DN80

Shape: Hex Head, Square Head and Round Head.

Thread Type: NPT, PT, BSPP, BSPT, PF

Size Range: 1/8" - 4" / DN6 - DN100

Type: Long Pattern (LP) and Short Pattern (SP)

Size Range: 1/2” - 24” / DN15 - 600

Thickness Schedule: SCH 10 - SCH 160, XXS

| Availability: | |

|---|---|

| Quantity: | |

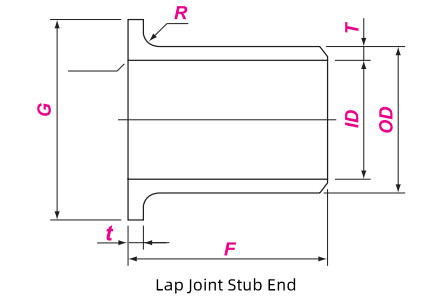

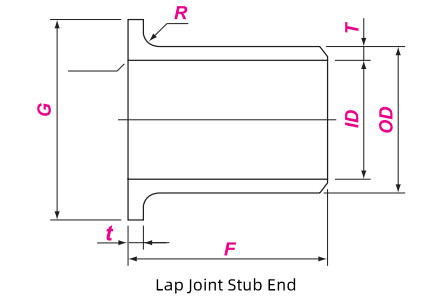

Lap joint stub end is generally matched with flange and benefit the flange to align bolt holes smoothly. There are two types that long pattern and short pattern.

ASME B16.9 lap joint stub end have a flanged structure at one end. This flange is usually for easy connection with other flanges or pipe fittings. ASME B16.9 is a standard for factory-made forged steel butt-weld pipe fittings established by the American Society of Mechanical Engineers (ASME). As one of the pipe fittings, the lap joint stub end have specific functions and application requirements in the piping system. The shape and size of the flange follow the ASME B16.9 standard, including the outer diameter, thickness and other parameters.

Buttwelding Fittings are used in a piping system to change direction or function of media, to branch off, reduce pipe size or attach auxiliary equipment. They are availbale in multiple types as elbow, tee, cap, reducer, stub end and oelt, that produced in cold and hot forming based on ASTM A403 and ASTM A234 specification.

ASTM A403 Specificaiton

This specification covers wrought stainles steel fittings for pressure piping applications. They are designed in WP or CR based on ASME or MSS standard dimensions. You need to indicate seamless or welded type while purchasing WP grades fittings.

ASTM A234 Specification

This specifiation covers wrought carbon steel and alloy steel fittings of semaless and welded construction by the standard of ASME B16.9, B16.11, MSS-SP-79, MSS-SP-83, MSS-SP-95 and MSS -SP-97. These fittings are for use in pressure piping and in pressure vessel fabrication for service at moderate and elevated temperatures.

Lap Joint Stub End Type & Material

| Type | Long Pattern (LP) and Short Pattern (SP) |

| Size Range | 1/2” - 24” / DN15 - 600 |

| Thickness Schedule | SCH 10 - SCH 160, XXS |

| China Standard | GB/T12459, GB/T13401, HG/T21635/21631, SH3408/3409 |

| America Standard | ANSI / ASME B16.9 / MSS SP 43 |

| Japan Standard | JIS B2311/2312/2313 |

| Germany Standard | DIN2605/2615/2616/2617 |

| Europe Standard | EN10253 |

| Carbon Steel | Q235, 20#, 35#, 45#, 20G,ASTM A234 WPB/WPC |

| Low Temp Carbon Steel | Q345B, 16Mn, ASTM A420 WPL6 |

| Pipeline Steel | ASTM A860 WPHY 42 / 46 / 56 / 60 / 65 |

| Alloy Steel | ASTM A234 WP11 / WP12 / WP 5 / WP9 / WP91 / WP92, 15CrMoG, 12Cr1MoVG, 12Cr5Mo, 1Cr5Mo, Cr9Mo, 10CrMo910, 12CrMo4-5 |

| Stainless Steel | ASTM A403 WP304/304L/304H, 316/316L, 310S, 317,347,904L |

| Duplex Stainless Steel | ASTM A815 S32205, S31803, 32750, 32760 |

Lap Joint Stub End Dimensions & Weight

| DN | NPS | OD | F | R | G | SCH40 WEIGHT | |||||

| Max. | Min. | Long Type | Short Type | A | Bmax | LP (kg) | SP (kg) | ||||

| 15 | 1/2 | 22.8 | 20.5 | 76 | 51 | 3 | 0.8 | 35 | 0.12 | 0.09 | |

| 20 | 3/4 | 28.1 | 25.9 | 76 | 51 | 3 | 0.8 | 43 | 0.16 | 0.12 | |

| 25 | 1 | 35.0 | 32.6 | 102 | 51 | 3 | 0.8 | 51 | 0.32 | 0.18 | |

| 32 | 11/4 | 43.6 | 41.4 | 102 | 51 | 5 | 0.8 | 64 | 0.43 | 0.25 | |

| 40 | 11/2 | 49.9 | 47.5 | 102 | 51 | 6 | 0.8 | 73 | 0.52 | 0.31 | |

| 50 | 2 | 62.4 | 59.5 | 152 | 64 | 8 | 0.8 | 92 | 1.02 | 0.52 | |

| 65 | 21/2 | 75.3 | 72.2 | 152 | 64 | 8 | 0.8 | 105 | 1.60 | 0.81 | |

| 80 | 3 | 91.3 | 88.1 | 152 | 64 | 10 | 0.8 | 127 | 2.11 | 1.10 | |

| 90 | 31/2 | 104.0 | 100.8 | 152 | 76 | 10 | 0.8 | 140 | 2.55 | 1.52 | |

| 100 | 4 | 116.7 | 113.5 | 152 | 76 | 11 | 0.8 | 157 | 3.05 | 1.80 | |

| 125 | 5 | 144.3 | 140.5 | 203 | 76 | 11 | 1.6 | 186 | 5.42 | 2.25 | |

| 150 | 6 | 171.3 | 167.5 | 203 | 89 | 13 | 1.6 | 216 | 7.02 | 3.59 | |

| 200 | 8 | 222.1 | 218.3 | 203 | 102 | 13 | 1.6 | 270 | 10.6 | 5.98 | |

| 250 | 10 | 277.2 | 272.3 | 254 | 127 | 13 | 1.6 | 324 | 18.4 | 10.2 | |

| 300 | 12 | 328.0 | 323.1 | 254 | 152 | 13 | 1.6 | 381 | 22.8 | 14.9 | |

| 350 | 14 | 359.9 | 354.8 | 305 | 152 | 13 | 1.6 | 413 | 28.7 | 15.8 | |

| 400 | 16 | 411.0 | 405.6 | 305 | 152 | 13 | 1.6 | 470 | 33.1 | 18.9 | |

| 450 | 18 | 462.0 | 456.0 | 305 | 152 | 13 | 1.6 | 533 | 38.0 | 22.0 | |

| 500 | 20 | 514.0 | 507.0 | 305 | 152 | 13 | 1.6 | 584 | 42.3 | 24.3 | |

| 550 | 22 | 565.0 | 558.0 | 305 | 152 | 13 | 1.6 | 641 | - | - | |

| 600 | 24 | 616.0 | 609.0 | 305 | 152 | 13 | 1.6 | 692 | 51.2 | 29.6 | |

Notes:

1) When the short type is used on the larger flanges with PN50 and PN110(300 and 600LB)and on flanges with PN150(900LB) and above, or the long type is used on the larger flange with PN260 and PN420(1500 and 2500LB),the length of the cylinder may be added to be feasible the welding,the adding length shall be negotiated by manufacturer and purchaser.

2) The thickness of joint shall be added if the TG and MFM contact surface of flange are used, and the adding thickness shall increase (not be included in) the base length F.

3) The radius of fillet R (type A) shall conform to the ones of loose flanges according to GB/T9118.1~9118.2 or ASME B16.5. The radius of fillet R (type B) is only applied for the standards of MSS SP-43 with short length F.

4) The lap joint diameter G shall conform to the standard machined face indicated in ASME b16.5, and the back of joint shall be machined to conform to the surface of installation.When RJ used, the size K specified in ASME B16.5 shall apply.

5) The minimum lap joint thickness t shall not be less than nominal pipe wall thickness.

Application fields of ASME B16.9 Lap Joint Stub End

●Petrochemical Industry

ASME B16.9 lap joint stub ends are widely used in the process of petroleum refining and chemical production. In chemical plants, for pipelines conveying corrosive media, flanged nipples can ensure the sealing and connection reliability of the pipeline system, prevent medium leakage, and ensure production safety.

●Power Industry

Lap joint stub end are also important in thermal power generation and nuclear power generation systems. In steam pipe systems, it can be used to connect pipes of different pressure levels or pipe diameters to ensure efficient steam delivery.

●Building HVAC Industry

Lap joint stub end can be used to connect pipes of different specifications, such as air conditioning chilled water pipes, hot water pipes, etc. It can meet the system's requirements for sealing and aesthetics while ensuring pipe connection, and facilitate the installation, maintenance and overhaul of the pipeline system.

Lap joint stub end is generally matched with flange and benefit the flange to align bolt holes smoothly. There are two types that long pattern and short pattern.

ASME B16.9 lap joint stub end have a flanged structure at one end. This flange is usually for easy connection with other flanges or pipe fittings. ASME B16.9 is a standard for factory-made forged steel butt-weld pipe fittings established by the American Society of Mechanical Engineers (ASME). As one of the pipe fittings, the lap joint stub end have specific functions and application requirements in the piping system. The shape and size of the flange follow the ASME B16.9 standard, including the outer diameter, thickness and other parameters.

Buttwelding Fittings are used in a piping system to change direction or function of media, to branch off, reduce pipe size or attach auxiliary equipment. They are availbale in multiple types as elbow, tee, cap, reducer, stub end and oelt, that produced in cold and hot forming based on ASTM A403 and ASTM A234 specification.

ASTM A403 Specificaiton

This specification covers wrought stainles steel fittings for pressure piping applications. They are designed in WP or CR based on ASME or MSS standard dimensions. You need to indicate seamless or welded type while purchasing WP grades fittings.

ASTM A234 Specification

This specifiation covers wrought carbon steel and alloy steel fittings of semaless and welded construction by the standard of ASME B16.9, B16.11, MSS-SP-79, MSS-SP-83, MSS-SP-95 and MSS -SP-97. These fittings are for use in pressure piping and in pressure vessel fabrication for service at moderate and elevated temperatures.

Lap Joint Stub End Type & Material

| Type | Long Pattern (LP) and Short Pattern (SP) |

| Size Range | 1/2” - 24” / DN15 - 600 |

| Thickness Schedule | SCH 10 - SCH 160, XXS |

| China Standard | GB/T12459, GB/T13401, HG/T21635/21631, SH3408/3409 |

| America Standard | ANSI / ASME B16.9 / MSS SP 43 |

| Japan Standard | JIS B2311/2312/2313 |

| Germany Standard | DIN2605/2615/2616/2617 |

| Europe Standard | EN10253 |

| Carbon Steel | Q235, 20#, 35#, 45#, 20G,ASTM A234 WPB/WPC |

| Low Temp Carbon Steel | Q345B, 16Mn, ASTM A420 WPL6 |

| Pipeline Steel | ASTM A860 WPHY 42 / 46 / 56 / 60 / 65 |

| Alloy Steel | ASTM A234 WP11 / WP12 / WP 5 / WP9 / WP91 / WP92, 15CrMoG, 12Cr1MoVG, 12Cr5Mo, 1Cr5Mo, Cr9Mo, 10CrMo910, 12CrMo4-5 |

| Stainless Steel | ASTM A403 WP304/304L/304H, 316/316L, 310S, 317,347,904L |

| Duplex Stainless Steel | ASTM A815 S32205, S31803, 32750, 32760 |

Lap Joint Stub End Dimensions & Weight

| DN | NPS | OD | F | R | G | SCH40 WEIGHT | |||||

| Max. | Min. | Long Type | Short Type | A | Bmax | LP (kg) | SP (kg) | ||||

| 15 | 1/2 | 22.8 | 20.5 | 76 | 51 | 3 | 0.8 | 35 | 0.12 | 0.09 | |

| 20 | 3/4 | 28.1 | 25.9 | 76 | 51 | 3 | 0.8 | 43 | 0.16 | 0.12 | |

| 25 | 1 | 35.0 | 32.6 | 102 | 51 | 3 | 0.8 | 51 | 0.32 | 0.18 | |

| 32 | 11/4 | 43.6 | 41.4 | 102 | 51 | 5 | 0.8 | 64 | 0.43 | 0.25 | |

| 40 | 11/2 | 49.9 | 47.5 | 102 | 51 | 6 | 0.8 | 73 | 0.52 | 0.31 | |

| 50 | 2 | 62.4 | 59.5 | 152 | 64 | 8 | 0.8 | 92 | 1.02 | 0.52 | |

| 65 | 21/2 | 75.3 | 72.2 | 152 | 64 | 8 | 0.8 | 105 | 1.60 | 0.81 | |

| 80 | 3 | 91.3 | 88.1 | 152 | 64 | 10 | 0.8 | 127 | 2.11 | 1.10 | |

| 90 | 31/2 | 104.0 | 100.8 | 152 | 76 | 10 | 0.8 | 140 | 2.55 | 1.52 | |

| 100 | 4 | 116.7 | 113.5 | 152 | 76 | 11 | 0.8 | 157 | 3.05 | 1.80 | |

| 125 | 5 | 144.3 | 140.5 | 203 | 76 | 11 | 1.6 | 186 | 5.42 | 2.25 | |

| 150 | 6 | 171.3 | 167.5 | 203 | 89 | 13 | 1.6 | 216 | 7.02 | 3.59 | |

| 200 | 8 | 222.1 | 218.3 | 203 | 102 | 13 | 1.6 | 270 | 10.6 | 5.98 | |

| 250 | 10 | 277.2 | 272.3 | 254 | 127 | 13 | 1.6 | 324 | 18.4 | 10.2 | |

| 300 | 12 | 328.0 | 323.1 | 254 | 152 | 13 | 1.6 | 381 | 22.8 | 14.9 | |

| 350 | 14 | 359.9 | 354.8 | 305 | 152 | 13 | 1.6 | 413 | 28.7 | 15.8 | |

| 400 | 16 | 411.0 | 405.6 | 305 | 152 | 13 | 1.6 | 470 | 33.1 | 18.9 | |

| 450 | 18 | 462.0 | 456.0 | 305 | 152 | 13 | 1.6 | 533 | 38.0 | 22.0 | |

| 500 | 20 | 514.0 | 507.0 | 305 | 152 | 13 | 1.6 | 584 | 42.3 | 24.3 | |

| 550 | 22 | 565.0 | 558.0 | 305 | 152 | 13 | 1.6 | 641 | - | - | |

| 600 | 24 | 616.0 | 609.0 | 305 | 152 | 13 | 1.6 | 692 | 51.2 | 29.6 | |

Notes:

1) When the short type is used on the larger flanges with PN50 and PN110(300 and 600LB)and on flanges with PN150(900LB) and above, or the long type is used on the larger flange with PN260 and PN420(1500 and 2500LB),the length of the cylinder may be added to be feasible the welding,the adding length shall be negotiated by manufacturer and purchaser.

2) The thickness of joint shall be added if the TG and MFM contact surface of flange are used, and the adding thickness shall increase (not be included in) the base length F.

3) The radius of fillet R (type A) shall conform to the ones of loose flanges according to GB/T9118.1~9118.2 or ASME B16.5. The radius of fillet R (type B) is only applied for the standards of MSS SP-43 with short length F.

4) The lap joint diameter G shall conform to the standard machined face indicated in ASME b16.5, and the back of joint shall be machined to conform to the surface of installation.When RJ used, the size K specified in ASME B16.5 shall apply.

5) The minimum lap joint thickness t shall not be less than nominal pipe wall thickness.

Application fields of ASME B16.9 Lap Joint Stub End

●Petrochemical Industry

ASME B16.9 lap joint stub ends are widely used in the process of petroleum refining and chemical production. In chemical plants, for pipelines conveying corrosive media, flanged nipples can ensure the sealing and connection reliability of the pipeline system, prevent medium leakage, and ensure production safety.

●Power Industry

Lap joint stub end are also important in thermal power generation and nuclear power generation systems. In steam pipe systems, it can be used to connect pipes of different pressure levels or pipe diameters to ensure efficient steam delivery.

●Building HVAC Industry

Lap joint stub end can be used to connect pipes of different specifications, such as air conditioning chilled water pipes, hot water pipes, etc. It can meet the system's requirements for sealing and aesthetics while ensuring pipe connection, and facilitate the installation, maintenance and overhaul of the pipeline system.