Views: 18 Author: Site Editor Publish Time: 2025-08-12 Origin: Site

As an indispensable infrastructure in modern industrial fields, pipeline systems undertake the important task of transporting various media. As an important connecting component in pipeline systems, the quality and performance of butt weld pipe fittings directly affect the safety and stable operation of the entire system. ASME B16.9 pipe fittings have become the preferred choice for many industrial projects due to their strict standard specifications, diverse types, excellent material properties, advanced production processes, and wide range of applications.

ASME B16.9 is an important standard specifically issued by the American Society of Mechanical Engineers (ASME) for butt weld pipe fittings. This standard provides detailed specifications for the dimensions, tolerances, pressure resistance, testing methods, and identification requirements of pipe fittings, ensuring their compatibility and integrity in industrial applications. Its size range is from 1/2"to 48", (DN15 to DN1200), suitable for various pipe fittings that can produce wall thicknesses. Butt Weld pipe fittings manufactured in accordance with ASME B16.9 standards can achieve precise docking and efficient operation in different industrial environments, providing a solid guarantee for the reliability of pipeline systems.

ASME B16.9 pipe fittings provides a wide variety of pipe fittings to meet the different needs of pipeline systems. Common types include butt weld elbows, tees, reducers, caps, and stub end.

Butt Weld Elbow

Used to change the direction of the pipeline, it can be divided into long radius elbows (1.5D) and short radius elbows (1D) according to the radius; According to the angle, it can be divided into 45 degree elbows, 90 degree elbows, and 180 degree elbows. According to the manufacturing process, elbows can be divided into push elbows, extruded elbows, and welded diagonal elbows.

Nominal Size | Outside Diameter at Bevel | Center to End | Center to Center | Back to Face | |||||

90° Elbows | 45° Elbows |

| |||||||

DN | NPS | OD | A | B | O | K | |||

LR | SR | LR | LR | SR | LR | SR | |||

15 | 1/2 | 21.3 | 38 | 16 | 76 | 48 | |||

20 | 3/4 | 26.7 | 38 | 19 | 76 | 51 | |||

25 | 1 | 33.4 | 38 | 25 | 22 | 76 | 51 | 56 | 41 |

32 | 1 1/4 | 42.2 | 48 | 32 | 25 | 95 | 64 | 70 | 52 |

40 | 1 1/2 | 48.3 | 57 | 38 | 29 | 114 | 76 | 83 | 62 |

50 | 2 | 60.3 | 76 | 51 | 35 | 152 | 102 | 106 | 81 |

65 | 2 1/2 | 73.0 | 95 | 64 | 44 | 190 | 127 | 132 | 100 |

80 | 3 | 88.9 | 114 | 76 | 51 | 229 | 152 | 159 | 121 |

90 | 3 1/2 | 101.6 | 133 | 4、89 | 57 | 267 | 178 | 184 | 140 |

100 | 4 | 114.3 | 152 | 102 | 64 | 305 | 203 | 210 | 159 |

125 | 5 | 141.3 | 190 | 127 | 79 | 381 | 254 | 262 | 197 |

150 | 6 | 168.3 | 229 | 152 | 95 | 457 | 305 | 313 | 237 |

200 | 8 | 219.1 | 305 | 203 | 127 | 610 | 406 | 414 | 313 |

250 | 10 | 273.0 | 381 | 254 | 159 |

| 508 | 518 | 391 |

300 | 12 | 323.8 | 457 | 305 | 190 | 914 | 609 | 619 | 467 |

350 | 14 | 355.6 | 533 | 356 | 222 | 1067 | 711 | 711 | 533 |

400 | 16 | 406.4 | 610 | 406 | 254 | 1219 | 813 | 813 | 610 |

450 | 18 | 457.0 | 686 | 457 | 286 | 1372 | 914 | 914 | 686 |

500 | 20 | 508.0 | 762 | 508 | 318 | 1524 | 1016 | 1016 | 762 |

550 | 22 | 559.0 | 838 | 559 | 343 | 1676 | 1118 | 1118 | 838 |

600 | 24 | 610.0 | 914 | 610 | 381 | 1829 | 1219 | 1219 | 914 |

650 | 26 | 660.0 | 991 | 660 | 406 | ||||

700 | 28 | 711.0 | 1067 | 711 | 438 | ||||

750 | 30 | 762.0 | 1143 | 762 | 470 | ||||

800 | 32 | 813.0 | 1219 | 813 | 502 | ||||

850 | 34 | 864.0 | 1295 | 864 | 533 | ||||

900 | 36 | 914.0 | 1372 | 914 | 565 | ||||

950 | 38 | 965.0 | 1448 | 965 | 600 | ||||

1000 | 40 | 1016.0 | 1524 | 1016 | 632 | ||||

1050 | 42 | 1067.0 | 1600 | 1067 | 660 | ||||

1100 | 44 | 1118.0 | 1676 | 1118 | 695 | ||||

1150 | 46 | 1168.0 | 1753 | 1168 | 727 | ||||

1200 | 48 | 1219.0 | 1829 | 1219 | 759 | ||||

ASME B16.9 Butt Weld Tee

According to the diameter of the branch pipe, it can be divided into equal tee and reducing tee. Equal tee with three ports of the same diameter, used to connect three pipes of the same diameter; Reducing tee can connect pipes of different diameters to achieve the diversion or merging of media, among which the Y-shaped tee can make the fluid branch at a certain angle and play an important role in specific pipeline layouts.

Nominal Size | Outside Diameter at Bevel | Center to End | ||

DN | NPS | OD1×OD2 | C | M |

15 | 1/2 | 21.3 | 25 | 25 |

20 | 3/4 | 26.7 | 29 | 29 |

25 | 1 | 33.4 | 38 | 38 |

32 | 11/4 | 42.2 | 48 | 48 |

40 | 11/2 | 48.3 | 57 | 57 |

50 | 2 | 60.3 | 64 | 64 |

65 | 21/2 | 73.0 | 76 | 76 |

80 | 3 | 88.9 | 86 | 86 |

90 | 31/2 | 101.6 | 95 | 95 |

100 | 4 | 114.3 | 105 | 105 |

125 | 5 | 141.3 | 124 | 124 |

150 | 6 | 168.3 | 143 | 143 |

200 | 8 | 219.1 | 178 | 178 |

250 | 10 | 273.0 | 216 | 216 |

300 | 12 | 323.8 | 254 | 254 |

350 | 14 | 355.6 | 279 | 279 |

400 | 16 | 406.4 | 305 | 305 |

450 | 18 | 457.0 | 343 | 343 |

500 | 20 | 508.0 | 381 | 381 |

550 | 22 | 559.0 | 419 | 419 |

600 | 24 | 610.0 | 432 | 432 |

650 | 26 | 660.0 | 495 | 495 |

700 | 28 | 711.0 | 521 | 521 |

750 | 30 | 762.0 | 559 | 559 |

800 | 32 | 813.0 | 597 | 597 |

850 | 34 | 864.0 | 635 | 635 |

900 | 36 | 914.0 | 673 | 673 |

950 | 38 | 965.0 | 711 | 711 |

1000 | 40 | 1016.0 | 749 | 749 |

1050 | 42 | 1067.0 | 762 | 711 |

1100 | 44 | 1118.0 | 813 | 762 |

1150 | 46 | 1168.0 | 851 | 800 |

1200 | 48 | 1219.0 | 889 | 838 |

CONC&ECC Reducer

Reducer is a special type of ASME B16.9 pipe fittings. Divided into concentric reducer and eccentric reducer. The central axis of the large and small ends of the concentric reducer coincides, mainly used to change the diameter of the pipeline and ensure a smooth transition of the fluid; The outer walls of the large and small ends of the eccentric reducer are in a straight line and are commonly used in situations where fluid height control or accumulation avoidance is required.

OD1 | OD2 | END TO END |

NPS | NPS | H |

3/4 | 3/8 - 1/2 | 38 |

1 | 1/2 - 3/4 | 51 |

1-1/4 | 1/2 - 1 | 51 |

1-1/2 | 1/2 - 1-1/4 | 64 |

2 | 3/4 - 1-1/2 | 76 |

2-1/2 | 1 - 2 | 89 |

3 | 1-1/4 - 2-1/2 | 102 |

4 | 2 - 3-1/2 | 102 |

5 | 2 - 4 | 127 |

6 | 2-1/2 - 5 | 140 |

8 | 3-1/2 - 6 | 152 |

10 | 4 - 8 | 178 |

12 | 5 - 10 | 203 |

14 | 6 - 12 | 330 |

16 | 6 - 14 | 356 |

18 | 8 - 16 | 381 |

20 | 10 - 18 | 508 |

22 | 12 - 20 | 508 |

24 | 12 - 22 | 508 |

26 | 12 - 24 | 610 |

28 | 14 - 26 | 610 |

30 | 14 - 28 | 610 |

32 | 20 - 30 | 610 |

34 | 22 - 32 | 610 |

36 | 22 - 34 | 610 |

38 | 24 - 36 | 610 |

40 | 28 - 38 | 610 |

42 | 28 - 40 | 610 |

44 | 32 - 42 | 610 |

46 | 34 - 44 | 711 |

48 | 36 - 46 | 711 |

Butt Weld Cap

Used to seal the end of pipelines, standard elliptical butt weld caps can withstand high pressure and are widely used in high-pressure pipeline systems.

DN | NPS | OD | E | E1 |

15 | 1/2 | 21.3 | 25 | 25 |

20 | 3/4 | 26.7 | 25 | 25 |

25 | 1 | 33.4 | 38 | 38 |

32 | 11/4 | 42.2 | 38 | 38 |

40 | 11/2 | 48.3 | 38 | 38 |

50 | 2 | 60.3 | 38 | 44 |

65 | 21/2 | 73.0 | 38 | 51 |

80 | 3 | 88.9 | 51 | 64 |

90 | 31/2 | 101.6 | 64 | 76 |

100 | 4 | 114.3 | 64 | 76 |

125 | 5 | 141.3 | 76 | 89 |

150 | 6 | 168.3 | 89 | 102 |

200 | 8 | 219.1 | 102 | 127 |

250 | 10 | 273.0 | 127 | 152 |

300 | 12 | 323.8 | 152 | 178 |

350 | 14 | 355.6 | 165 | 191 |

400 | 16 | 406.4 | 178 | 203 |

450 | 18 | 457.0 | 203 | 229 |

500 | 20 | 508.0 | 229 | 254 |

550 | 22 | 559.0 | 254 | 254 |

600 | 24 | 610.0 | 267 | 305 |

650 | 26 | 660.0 | 267 | --- |

700 | 28 | 711.0 | 267 | --- |

750 | 30 | 762.0 | 267 | --- |

800 | 32 | 813.0 | 267 | --- |

850 | 34 | 864.0 | 267 | --- |

900 | 36 | 914.0 | 267 | --- |

950 | 38 | 965.0 | 305 | --- |

1000 | 40 | 1016.0 | 305 | --- |

1050 | 42 | 1067.0 | 305 | --- |

1100 | 44 | 1118.0 | 343 | --- |

1150 | 46 | 1168.0 | 343 | --- |

1200 | 48 | 1219.0 | 343 | --- |

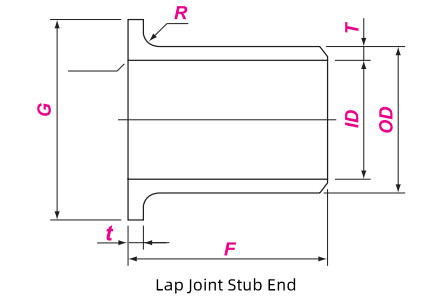

Stub End

Used in conjunction with lap joint flanges for pipeline connections, it provides a convenient connection method for installation and maintenance, effectively reducing the risk of leakage at pipeline connections.

DN | NPS | OD | F | R | G | SCH40 WEIGHT | ||||

Max. | Min. | Long Type | Short Type | A | Bmax | LP (kg) | SP (kg) | |||

15 | 1/2 | 22.8 | 20.5 | 76 | 51 | 3 | 0.8 | 35 | 0.12 | 0.09 |

20 | 3/4 | 28.1 | 25.9 | 76 | 51 | 3 | 0.8 | 43 | 0.16 | 0.12 |

25 | 1 | 35.0 | 32.6 | 102 | 51 | 3 | 0.8 | 51 | 0.32 | 0.18 |

32 | 11/4 | 43.6 | 41.4 | 102 | 51 | 5 | 0.8 | 64 | 0.43 | 0.25 |

40 | 11/2 | 49.9 | 47.5 | 102 | 51 | 6 | 0.8 | 73 | 0.52 | 0.31 |

50 | 2 | 62.4 | 59.5 | 152 | 64 | 8 | 0.8 | 92 | 1.02 | 0.52 |

65 | 21/2 | 75.3 | 72.2 | 152 | 64 | 8 | 0.8 | 105 | 1.60 | 0.81 |

80 | 3 | 91.3 | 88.1 | 152 | 64 | 10 | 0.8 | 127 | 2.11 | 1.10 |

90 | 31/2 | 104.0 | 100.8 | 152 | 76 | 10 | 0.8 | 140 | 2.55 | 1.52 |

100 | 4 | 116.7 | 113.5 | 152 | 76 | 11 | 0.8 | 157 | 3.05 | 1.80 |

125 | 5 | 144.3 | 140.5 | 203 | 76 | 11 | 1.6 | 186 | 5.42 | 2.25 |

150 | 6 | 171.3 | 167.5 | 203 | 89 | 13 | 1.6 | 216 | 7.02 | 3.59 |

200 | 8 | 222.1 | 218.3 | 203 | 102 | 13 | 1.6 | 270 | 10.6 | 5.98 |

250 | 10 | 277.2 | 272.3 | 254 | 127 | 13 | 1.6 | 324 | 18.4 | 10.2 |

300 | 12 | 328.0 | 323.1 | 254 | 152 | 13 | 1.6 | 381 | 22.8 | 14.9 |

350 | 14 | 359.9 | 354.8 | 305 | 152 | 13 | 1.6 | 413 | 28.7 | 15.8 |

400 | 16 | 411.0 | 405.6 | 305 | 152 | 13 | 1.6 | 470 | 33.1 | 18.9 |

450 | 18 | 462.0 | 456.0 | 305 | 152 | 13 | 1.6 | 533 | 38.0 | 22.0 |

500 | 20 | 514.0 | 507.0 | 305 | 152 | 13 | 1.6 | 584 | 42.3 | 24.3 |

550 | 22 | 565.0 | 558.0 | 305 | 152 | 13 | 1.6 | 641 | - | - |

600 | 24 | 616.0 | 609.0 | 305 | 152 | 13 | 1.6 | 692 | 51.2 | 29.6 |

ASME B16.9 pipe fittings are typically made of high-quality materials, commonly including carbon steel, stainless steel, and alloy steel.

Carbon steel pipe fittings: ASTM A234 WPB material is one of the commonly used materials in carbon steel pipe fittings.It has good strength and toughness, relatively low price, and is suitable for high-pressure and high-temperature medium transportation in general industrial environments, such as widely used in oil and gas pipelines.

Chemical Composition

| CHEMICAL | LIMITS | C | Mn | P | S | Si | Cr | Mo | Ni | Cu | V |

| ASTM A234 WPB | MIN | 0.29 | 0.10 | ||||||||

| MAX | 0.30 | 1.06 | 0.050 | 0.058 | 0.40 | 0.15 | 0.40 | 0.40 | 0.08 |

Mechanical Properties

| MATERIAL | T.S (MPA) | Y.S (MPA) | EL % | HARDNESS |

| ASTM A234 WPB | 415 min | 240 min | 22 min | 197 max |

Stainless steel fittings: Austenitic series stainless steel such as ASTM A403 WP304/316 has excellent corrosion resistance and can maintain good performance in harsh corrosive environments. In fields such as ocean engineering and chemical engineering, stainless steel pipe fittings have become an ideal choice due to the strong corrosiveness of the medium.

Chemical Composition

| CHEMICAL | LIMITS | C | Mn | P | S | Si | Ni | Cr | Mo |

| ASTM A403 WP304 | MIN | 8.0 | 18.0 | ||||||

| MAX | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 11.0 | 20.0 | ||

| ASTM A403 WP316 | MIN | 10.00 | 16.00 | 2.00 | |||||

| MAX | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 14.00 | 18.00 | 3.00 |

Mechanical Properties

| MATERIAL | ASTM A403 WP304 | ASTM A403 WP316 |

| T.S (MPA) | 515 min | 515 min |

| Y.S (MPA) | 205 min | 205 min |

| EL % | 28 min | 28 min |

Alloy steel pipe fittings: Suitable for working environments under extreme temperature and pressure conditions, the addition of alloy elements endows the fittings with higher strength and creep resistance, enabling them to operate stably under complex working conditions.

Chemical Composition

| CHEMICAL | LIMITS | C | Mn | P | S | Si | Cr | Mo |

| ASTM A234 WP12 CL1 | MIN | 0.050 | 0.30 | 0.80 | 0.440 | |||

| MAX | 0.200 | 0.80 | 0.045 | 0.045 | 0.60 | 1.25 | 0.650 | |

| ASTM A234 WP11 CL1 | MIN | 0.050 | 0.30 | 0.50 | 1.00 | 0.440 | ||

| MAX | 0.150 | 0.60 | 0.030 | 0.030 | 1.00 | 1.50 | 0.660 |

Mechanical Properties

| MATERIAL | T.S (MPA) | Y.S (MPA) | EL % |

| ASTM A234 WP12 CL1 | 415 min | 220min | 30min |

| ASTM A234 WP11 CL1 | 415 min | 205 min | 30min |

The production process of ASME B16.9 fittings is advanced and mature, mainly including the following:

1. Push molding: Mass production of commonly used butt welded elbows. By placing the tube blank in a specific mold and using a pushing machine to gradually deform it in the mold, the desired bend shape is formed. This process can ensure the dimensional accuracy and surface quality of the pipe fittings, and has high production efficiency.

2. Steel plate rolling welding: suitable for the manufacturing of large-diameter pipe fittings (generally DN350 or above). First, roll the steel plate into a cylindrical shape according to the design dimensions, and then weld it to form the main structure of the pipe fittings. The welding process strictly follows relevant standards to ensure reliable weld quality. For some large-diameter pipe fittings with special shapes, the steel plate rolling welding process has strong flexibility.

3. Hot press molding: This is a common process for manufacturing pipes such as reducers. A cylindrical billet made of steel pipes or steel plates with the same diameter and wall thickness as the product's large end is used as raw material, and is extruded and necked in a tire mold through local heating. The hot press molding process includes multiple steps such as cutting, local heating, compression molding, end shaping, weld inspection, heat treatment, surface treatment, and finished product inspection. Each step strictly controls the quality to ensure that the final product meets the ASME B16.9 standard.

ASME B16.9 pipe fittings are widely used in many industries due to their excellent performance.

1. Energy sector

2. Chemical industry

3. Architecture and Infrastructure

4. Other industries

With the continuous advancement of industrial technology and the increasing demand for pipeline system performance, ASME B16.9 pipe fittings will present the following development trends in the future:

1. Material innovation

2. Manufacturing process optimization

3. Green and environmentally friendly

4. Standardization and Internationalization

ASME B16.9 pipe fittings play an important role in industrial pipeline systems due to their strict standards, diverse types, clear size specifications, reasonable weight range, excellent material properties, advanced production processes, and wide application range. Its future development trend will also closely revolve around the needs of industrial development, constantly innovating and advancing. Whether it is existing industrial projects or emerging industries in the future, ASME B16.9 pipe fittings will continue to provide solid guarantees for the safe and efficient operation of pipeline systems, making them a reliable choice for industrial fittings.