Views: 729 Author: Good Du Publish Time: 2023-03-06 Origin: Site

The shipment charge is important in the offer of international trade.When we calculate shipment charge, we need to know the weight of pipe bend first.Sea transportation is common used for steel pipe bend due to the big dimension. In that case, the estimated weight is enough for the quotation. But when we shipment the steel pipe bend, we must make the perfect package and confirm the exact weight.

Steel pipe bend is a bending pipe that used to change the pipeline direction.

3D and 5D bend are common used radius bend. We also can manufacture the specific size for the customer.

It is similar to steel pipe elbow, the difference is bending radius and angles.

Bending Radius

While the bending radius is more than 3 times of D (diameter), it is pipe bend. Such as 3D bend, 5D bend, 6D pipe bend, 8D pipe bend.

While the bending radius is 1D or 1.5D, it is elbow. (short radius elbow 1D and long radius elbow 1.5D).

Angles

We can manufacture various angles according to client’s requirement.

45 degree, 90 degree and 180 degree are most common used for steel pipe bend and elbow.

Pipe Bend Specification

| Size Range | 1/2" - 48" / DN15 - 1200 |

| Thickness Schedule | SCH 10 - SCH 160, XXS |

| Bending Radius | R≥3D (R= 3D, 4D, 5D, 6D, 7D, 8D, 9D, 10D) |

| Standard | ASME B36.10 / ASME B36.19 / ASME B16.49 |

| Carbon Steel Material | ASTM A106B / A53B, API 5L B / X42 / X46 / X52 / X56 / X60 / X65 / X70, A333 GR 6 |

| Alloy Steel Material | ASTM A335 P11 / P12 / P22 / P 5 / P9 / P91 / P92,15CrMoG, 12Cr1MoVG, 12Cr5Mo, 1Cr5Mo, Cr9Mo, 10CrMo910, 12CrMo4-5 |

| Stainless Steel Material | ASTM A312 TP304/304L/304H, 316/316L, 310S, 317, 347, 904L |

| Bend Radius | R≥3OD(OD is outside diameter of pipe) |

| Bend Angle | According to the specification of design documentation. |

| Tangent Length | Per standard or specified length in the design documentation,or both straight lengths are 500mm. |

| Outside Diameter | OD≤1200mm |

| Wall Thickness | According to the specification of design documentation. |

| Bevel at Ends | According to the bevel ends of BW fiftings or per specification of design documentation. |

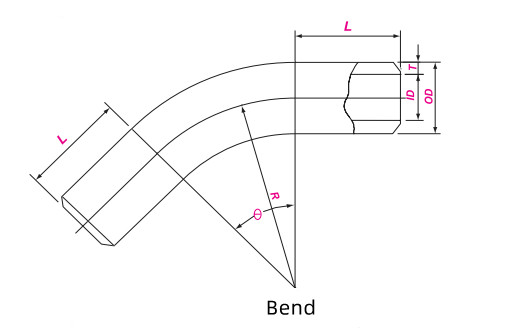

The bend’s wall thickness, radius and outside diameter is essential if you want to calculate the weight. And all the elements should have their exact values in mm. The formula to calculate these 90 degree pipe bend is

W= 0.0387 * S*(D – S) * R / 1000

W means Weight. The unit is Kg/piece.

S refers to the wall thickness schedule.

D is nominal diameter.

For the nominal diameter, you can refer to the weight list of pipe. The butt weld pipe fitting is manufactured by pipes, so the nominal diameter is same between pipes, pipe fittings, including the pipe bend.

R meas bending radius.

The formula can also be used with steel pipe elbow.

For the 45 degree pipe bend, the estimate weight is 0.6 times of 90 degree.

For the 180 degree pipe bend, the estimate weight is 2 times of 90 degree.

However, due to the steel pipe bend weight calculator is quite complicated, sometimes we will make a mistake.

For getting the correct value, it is very important to get accurate values of each element given in the formula, in mm. This would take up more time.

In that case, we make the 3D steel pipe bend weight list which can replace the calculation.

| DN | NPS | Sch20 | Sch30 | STD | Sch40 | Sch60 | XS | Sch80 | Sch100 | Sch120 | Sch160 | XXS |

| 20 | 0.14 | 0.17 | 0.17 | 0.22 | 0.22 | 0.29 | 0.36 | |||||

| 25 | 1 | 0.29 | 0.33 | 0.33 | 0.43 | 0.43 | 0.56 | 0.72 | ||||

| 32 | 1¼ | 0.47 | 0.56 | 0.56 | 0.48 | 0.48 | 0.92 | 1.28 | ||||

| 40 | 1½ | 0.70 | 0.80 | 0.80 | 1.07 | 1.07 | 1.43 | 1.88 | ||||

| 50 | 2 | 1.18 | 1.43 | 1.43 | 1.97 | 1.97 | 2.92 | 3.53 | ||||

| 65 | 2½ | 2.64 | 2.83 | 2.83 | 3.75 | 3.75 | 4.90 | 6.70 | ||||

| 80 | 3 | 3.92 | 4.47 | 4.47 | 6.04 | 6.04 | 8.45 | 11.0 | ||||

| 90 | 3½ | 5.27 | 6.26 | 6.26 | 8.60 | 8.60 | ||||||

| 100 | 4 | 6.80 | 8.47 | 8.47 | 11.8 | 11.8 | 14.9 | 17.7 | 21.6 | |||

| 125 | 5 | 14.3 | 14.3 | 20.4 | 20.4 | 26.5 | 32.3 | 37.8 | ||||

| 150 | 6 | 22.3 | 22.3 | 33.6 | 33.6 | 42.8 | 53.4 | 62.6 | ||||

| 200 | 8 | 35.1 | 38.8 | 44.8 | 44.8 | 56.0 | 68.1 | 68.1 | 80.0 | 95.3 | 117 | 114 |

| 250 | 10 | 55.0 | 67.2 | 79.4 | 79.4 | 107 | 107 | 126 | 151 | 175 | 227 | 204 |

| 300 | 12 | 78.5 | 103 | 117 | 126 | 172 | 154 | 209 | 252 | 295 | 377 | 295 |

| 350 | 14 | 125 | 150 | 150 | 174 | 234 | 198 | 292 | 359 | 414 | 519 | |

| 400 | 16 | 164 | 196 | 196 | 260 | 337 | 260 | 429 | 517 | 604 | 770 | |

| 450 | 18 | 208 | 290 | 249 | 369 | 488 | 330 | 604 | 734 | 862 | 1089 | |

| 500 | 20 | 309 | 409 | 309 | 483 | 653 | 409 | 819 | 1005 | 1163 | 1487 | |

| 550 | 22 | 374 | 496 | 374 | 852 | 496 | 1083 | 1307 | 1526 | 1947 | ||

| 600 | 24 | 446 | 663 | 446 | 807 | 1123 | 591 | 1397 | 1731 | 2023 | 2554 | |

| 650 | 26 | 694 | 523 | 694 | ||||||||

| 700 | 28 | 806 | 1004 | 608 | 806 | |||||||

| 750 | 30 | 927 | 1154 | 699 | 927 | |||||||

| 800 | 32 | 1056 | 1315 | 796 | 1445 | 1056 | ||||||

| 850 | 34 | 1194 | 1487 | 899 | 1634 | 1194 | ||||||

| 900 | 36 | 1338 | 1667 | 1008 | 1993 | 1338 | ||||||

| 950 | 38 | 1124 | 1493 | |||||||||

| 1000 | 40 | 1246 | 1655 | |||||||||

| 1050 | 42 | 1374 | 1826 | |||||||||

| 1100 | 44 | 1509 | 2006 | |||||||||

| 1150 | 46 | 1649 | 2191 | |||||||||

| 1200 | 48 | 1797 | 2388 |

Application Areas of Pipe Bending

Petrochemical Industry

In the petrochemical production process, various fluid media (such as crude oil, natural gas, chemical raw materials, etc.) need to be transported, reacted and separated in a complex pipeline system. As an important part of the pipeline system, bends can meet the connection requirements between different process equipment and enable the fluid to flow along a predetermined route.

Power Industry

In thermal power plants, bends are used in pipeline systems for transporting steam, water and various auxiliary media. In nuclear power plants, bends also play an important role in transporting special media such as coolants and nuclear fuel to ensure the safe operation of nuclear power plants.

Machine Tool Equipment

In machine tool equipment,bends are often used in cooling systems and lubrication systems.

Automated Production Lines

In automated production lines, bends are used to transport various gases, liquids and materials.