Size Range: 1/2" - 80" / DN15 - 2000

Thickness Schedule: SCH 10 - SCH 160, XXS

Standard: ANSI / ASME B16.9 / MSS SP 43

Size Range: 1/2" - 80" / DN15 - 2000

Thickness Schedule: SCH 10 - SCH 160, XXS

Standard: ANSI / ASME B16.9 / MSS SP 43

Size Range: 1/2" - 48" / DN15 - 1200

Thickness Schedule: SCH 10 - SCH 160, XXS

Standard: ANSI / ASME B16.9

We are a manufacturer, supplier and exporter of ASME B16.9 butt weld equal and reducing tee in China.

ANSI / ASME B16.9 steel pipe tee dimensions and weight chart is free for you.

Shape Type: Equal and Reducing

Size Range: 1/2" - 80" / DN15 - 2000

Thickness Schedule: SCH 10 - SCH 160, XXS

Standard: ANSI / ASME B16.9

Type: Long Pattern (LP) and Short Pattern (SP)

Size Range: 1/2” - 24” / DN15 - 600

Thickness Schedule: SCH 10 - SCH 160, XXS

Size Range: 3/4" - 60" / DN20 - 1500

Thickness Schedule: SCH 10 - SCH 160, XXS

Standard: ANSI / ASME B16.9 / MSS SP 43

Size Range: 3/4" - 60" / DN20 - 1500

Thickness Schedule: SCH 10 - SCH 160, XXS

Standard: ANSI / ASME B16.9 & MSS SP-43

Size Range: 1/2" - 48" / DN15 - 1200

Thickness Schedule: SCH 10 - SCH 160, XXS

Standard: ANSI / ASME B16.9

Type: 90 Degree and 45 Degree

Shape: Straight and Reducing Elbow

Size: 1/8” – 4” / DN6 - DN100

Shape: Equal and Reducing Tee

Size: 1/8"- 4" / DN6 - DN100

Pressure: Class 3000LBS, 6000Lbs, 9000lbs.

Standard: ASME B16.11, BS3799

Shape: Equal Cross Tee and Reducing Cross Tee

Size Range: 1/8” – 4” / DN6 - DN100

Pressure Rating: Class 3000lbs, 6000lbs, 9000lbs.

Standard: GB/T 14383, ASME B16.11, BS3799

Type: Full Coupling and Half Coupling

Shape: Straight Coupling and Reducing Coupling

Size Range: 1/8” – 4” / DN6 - DN100

Pressure Rating: Class 3000lbs, 6000lbs, 9000lbs

Size Range: 1/8” - 3” / DN6 - DN80

Pressure Rating: Class 3000lbs

Standard: MSS SP-83

Type: 90 Degree and 45 Degree Elbow

Shape: Straight and Reducing Elbow

Thread Type: NPT, PT, BSPP, BSPT, PF

Shape: Equal and Reducing Tee

Size Range: 1/8” – 4” / DN6 - DN100

Pressure Rating: Class 2000 lbs, 3000 lbs, 6000 lbs

Shape: Equal and Reducing

Size: 1/8" - 4" / DN6 - DN100

Pressure: Class 2000 lbs, 3000 lbs, 6000 lbs

Type: Full and Half Coupling

Shape: Straight and Reducing Coupling

Thread Type: NPT, PT, BSPP, BSPT, PF

Size Range: 1/8” – 4” / DN6 - DN100

Pressure Rating: Class 3000lbs, 6000lbs

Standard: ASME B16.11, BS3799, EN 10241

Size Range: 1/8” - 3” / DN6 - DN80

Pressure Rating: Class 3000lbs

Standard: MSS SP-83

Shape: Threaded One End (TOE) and Threaded Both End (TBE)

Size : 1/4” - 12” / DN8 - DN300

Thickness : Sch 10 - Sch 160 / XXS

Shape: Concentric and Eccentric

Size: 1/4" - 12" / DN8 - DN300

Thickness: Sch 10 - Sch 160 / XXS

Shape: Equal and Reducing

Thread Type: NPT, PT, BSPP, BSPT, PF

Size Range: 1/8” - 3” / DN6 - DN80

Shape: Hex Head, Square Head and Round Head.

Thread Type: NPT, PT, BSPP, BSPT, PF

Size Range: 1/8" - 4" / DN6 - DN100

Size Range: 1/2" - 48" / DN15 - 1200

Thickness Schedule: SCH 10 - SCH 160, XXS

Standard: ANSI / ASME B16.9

| Availability: | |

|---|---|

| Quantity: | |

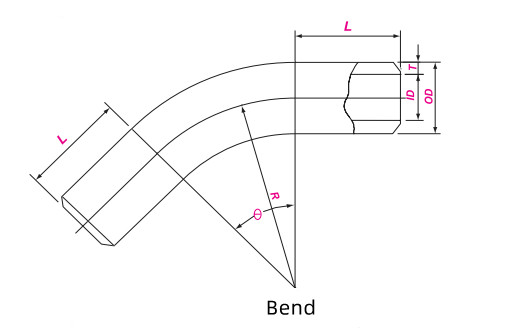

90 degree steel pipe bends are similar to elbows but bending radius is larger or equal to 3D, the common used type is 3D and 5D bend. It is usually used in the oil and gas industries. We usually provide steel pipe bends and elbows in material of alloy steel, carbon steel and stainless steel.

Buttwelding Fittings are used in a piping system to change direction or function of media, to branch off, reduce pipe size or attach auxiliary equipment. They are availbale in multiple types as elbow, tee, cap, reducer, stub end and oelt, that produced in cold and hot forming based on stainless steel and carbon steel material.

Seel pipe bends and elbows are used to change direction in piping system. And connecting with pipeline for transfering medium such as water, air, oil, gas and so on. But there are some differences between them as following.

Process

Seamless steel pipe elbows are produced by hot pressing or cold pressing. While the pipe bends are used medium frequency bending in hot or cold methods. Whatever hot or cold method, it depends on the material.

Angle

For pipe elbows, they have angles of 45 degree, 90 degree and 180 degree. While pipe bends are 22.5 degree, 30 degree, 45 degree and 90 degree.

Radius

Steel pipe bends have larger radius than elbows. Usually the elbows have two types that long radius (1.5D) and short radius (1D). For pipe bends, the bending radius ≥3D.

Cost

It will use more original material for making steel pipe bends due to the larger raidus, that would spend more money on the steel pipes. In addtion that take more space and increase the freight in transporation. So steel pipe bend price is expensive than elbow in same size and material.

Standard

Steel pipe elbows are manufactured in buttwelding fittings standard of ASME B16.9, but pipe bends are according to pipe standard that ASME B36.10 and ASME B36.19.

Tangent

The tangent length of steel pipe bends are 300 - 1500mm for both ends, while elbows do not have tangent.

SEAMLESS 90 & 45 DEGREE BEND 4D 1 1/2" SCH 80 ASTM A53B

We inspect the carbon steel A53 pipe bends before packing, to make customers satisfied after receive these goods.

| Size Range | 1/2" - 48" / DN15 - 1200 |

| Thickness Schedule | SCH 10 - SCH 160, XXS |

| Bending Radius | R≥3D (R= 3D, 4D, 5D, 6D, 7D, 8D, 9D, 10D) |

| Standard | ASME B36.10 / ASME B36.19 / ASME B16.49 |

| Carbon Steel Material | ASTM A106B / A53B, API 5L B / X42 / X46 / X52 / X56 / X60 / X65 / X70, A333 GR 6 |

| Alloy Steel Material | ASTM A335 P11 / P12 / P22 / P 5 / P9 / P91 / P92,15CrMoG, 12Cr1MoVG, 12Cr5Mo, 1Cr5Mo, Cr9Mo, 10CrMo910, 12CrMo4-5 |

| Stainless Steel Material | ASTM A312 TP304/304L/304H, 316/316L, 310S, 317, 347, 904L |

| Bend Radius | R≥3OD(OD is outside diameter of pipe) |

| Bend Angle | According to the specification of design documentation. |

| Tangent Length | Per standard or specified length in the design documentation,or both straight lengths are 500mm. |

| Outside Diameter | OD≤1200mm |

| Wall Thickness | According to the specification of design documentation. |

| Bevel at Ends | According to the bevel ends of BW fiftings or per specification of design documentation. |

| DN | NPS | Sch20 | Sch30 | STD | Sch40 | Sch60 | XS | Sch80 | Sch100 | Sch120 | Sch160 | XXS |

| 20 | 0.14 | 0.17 | 0.17 | 0.22 | 0.22 | 0.29 | 0.36 | |||||

| 25 | 1 | 0.29 | 0.33 | 0.33 | 0.43 | 0.43 | 0.56 | 0.72 | ||||

| 32 | 1¼ | 0.47 | 0.56 | 0.56 | 0.48 | 0.48 | 0.92 | 1.28 | ||||

| 40 | 1½ | 0.70 | 0.80 | 0.80 | 1.07 | 1.07 | 1.43 | 1.88 | ||||

| 50 | 2 | 1.18 | 1.43 | 1.43 | 1.97 | 1.97 | 2.92 | 3.53 | ||||

| 65 | 2½ | 2.64 | 2.83 | 2.83 | 3.75 | 3.75 | 4.90 | 6.70 | ||||

| 80 | 3 | 3.92 | 4.47 | 4.47 | 6.04 | 6.04 | 8.45 | 11.0 | ||||

| 90 | 3½ | 5.27 | 6.26 | 6.26 | 8.60 | 8.60 | ||||||

| 100 | 4 | 6.80 | 8.47 | 8.47 | 11.8 | 11.8 | 14.9 | 17.7 | 21.6 | |||

| 125 | 5 | 14.3 | 14.3 | 20.4 | 20.4 | 26.5 | 32.3 | 37.8 | ||||

| 150 | 6 | 22.3 | 22.3 | 33.6 | 33.6 | 42.8 | 53.4 | 62.6 | ||||

| 200 | 8 | 35.1 | 38.8 | 44.8 | 44.8 | 56.0 | 68.1 | 68.1 | 80.0 | 95.3 | 117 | 114 |

| 250 | 10 | 55.0 | 67.2 | 79.4 | 79.4 | 107 | 107 | 126 | 151 | 175 | 227 | 204 |

| 300 | 12 | 78.5 | 103 | 117 | 126 | 172 | 154 | 209 | 252 | 295 | 377 | 295 |

| 350 | 14 | 125 | 150 | 150 | 174 | 234 | 198 | 292 | 359 | 414 | 519 | |

| 400 | 16 | 164 | 196 | 196 | 260 | 337 | 260 | 429 | 517 | 604 | 770 | |

| 450 | 18 | 208 | 290 | 249 | 369 | 488 | 330 | 604 | 734 | 862 | 1089 | |

| 500 | 20 | 309 | 409 | 309 | 483 | 653 | 409 | 819 | 1005 | 1163 | 1487 | |

| 550 | 22 | 374 | 496 | 374 | 852 | 496 | 1083 | 1307 | 1526 | 1947 | ||

| 600 | 24 | 446 | 663 | 446 | 807 | 1123 | 591 | 1397 | 1731 | 2023 | 2554 | |

| 650 | 26 | 694 | 523 | 694 | ||||||||

| 700 | 28 | 806 | 1004 | 608 | 806 | |||||||

| 750 | 30 | 927 | 1154 | 699 | 927 | |||||||

| 800 | 32 | 1056 | 1315 | 796 | 1445 | 1056 | ||||||

| 850 | 34 | 1194 | 1487 | 899 | 1634 | 1194 | ||||||

| 900 | 36 | 1338 | 1667 | 1008 | 1993 | 1338 | ||||||

| 950 | 38 | 1124 | 1493 | |||||||||

| 1000 | 40 | 1246 | 1655 | |||||||||

| 1050 | 42 | 1374 | 1826 | |||||||||

| 1100 | 44 | 1509 | 2006 | |||||||||

| 1150 | 46 | 1649 | 2191 | |||||||||

| 1200 | 48 | 1797 | 2388 |

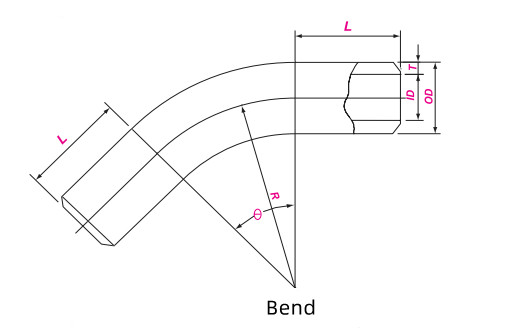

90 degree steel pipe bends are similar to elbows but bending radius is larger or equal to 3D, the common used type is 3D and 5D bend. It is usually used in the oil and gas industries. We usually provide steel pipe bends and elbows in material of alloy steel, carbon steel and stainless steel.

Buttwelding Fittings are used in a piping system to change direction or function of media, to branch off, reduce pipe size or attach auxiliary equipment. They are availbale in multiple types as elbow, tee, cap, reducer, stub end and oelt, that produced in cold and hot forming based on stainless steel and carbon steel material.

Seel pipe bends and elbows are used to change direction in piping system. And connecting with pipeline for transfering medium such as water, air, oil, gas and so on. But there are some differences between them as following.

Process

Seamless steel pipe elbows are produced by hot pressing or cold pressing. While the pipe bends are used medium frequency bending in hot or cold methods. Whatever hot or cold method, it depends on the material.

Angle

For pipe elbows, they have angles of 45 degree, 90 degree and 180 degree. While pipe bends are 22.5 degree, 30 degree, 45 degree and 90 degree.

Radius

Steel pipe bends have larger radius than elbows. Usually the elbows have two types that long radius (1.5D) and short radius (1D). For pipe bends, the bending radius ≥3D.

Cost

It will use more original material for making steel pipe bends due to the larger raidus, that would spend more money on the steel pipes. In addtion that take more space and increase the freight in transporation. So steel pipe bend price is expensive than elbow in same size and material.

Standard

Steel pipe elbows are manufactured in buttwelding fittings standard of ASME B16.9, but pipe bends are according to pipe standard that ASME B36.10 and ASME B36.19.

Tangent

The tangent length of steel pipe bends are 300 - 1500mm for both ends, while elbows do not have tangent.

SEAMLESS 90 & 45 DEGREE BEND 4D 1 1/2" SCH 80 ASTM A53B

We inspect the carbon steel A53 pipe bends before packing, to make customers satisfied after receive these goods.

| Size Range | 1/2" - 48" / DN15 - 1200 |

| Thickness Schedule | SCH 10 - SCH 160, XXS |

| Bending Radius | R≥3D (R= 3D, 4D, 5D, 6D, 7D, 8D, 9D, 10D) |

| Standard | ASME B36.10 / ASME B36.19 / ASME B16.49 |

| Carbon Steel Material | ASTM A106B / A53B, API 5L B / X42 / X46 / X52 / X56 / X60 / X65 / X70, A333 GR 6 |

| Alloy Steel Material | ASTM A335 P11 / P12 / P22 / P 5 / P9 / P91 / P92,15CrMoG, 12Cr1MoVG, 12Cr5Mo, 1Cr5Mo, Cr9Mo, 10CrMo910, 12CrMo4-5 |

| Stainless Steel Material | ASTM A312 TP304/304L/304H, 316/316L, 310S, 317, 347, 904L |

| Bend Radius | R≥3OD(OD is outside diameter of pipe) |

| Bend Angle | According to the specification of design documentation. |

| Tangent Length | Per standard or specified length in the design documentation,or both straight lengths are 500mm. |

| Outside Diameter | OD≤1200mm |

| Wall Thickness | According to the specification of design documentation. |

| Bevel at Ends | According to the bevel ends of BW fiftings or per specification of design documentation. |

| DN | NPS | Sch20 | Sch30 | STD | Sch40 | Sch60 | XS | Sch80 | Sch100 | Sch120 | Sch160 | XXS |

| 20 | 0.14 | 0.17 | 0.17 | 0.22 | 0.22 | 0.29 | 0.36 | |||||

| 25 | 1 | 0.29 | 0.33 | 0.33 | 0.43 | 0.43 | 0.56 | 0.72 | ||||

| 32 | 1¼ | 0.47 | 0.56 | 0.56 | 0.48 | 0.48 | 0.92 | 1.28 | ||||

| 40 | 1½ | 0.70 | 0.80 | 0.80 | 1.07 | 1.07 | 1.43 | 1.88 | ||||

| 50 | 2 | 1.18 | 1.43 | 1.43 | 1.97 | 1.97 | 2.92 | 3.53 | ||||

| 65 | 2½ | 2.64 | 2.83 | 2.83 | 3.75 | 3.75 | 4.90 | 6.70 | ||||

| 80 | 3 | 3.92 | 4.47 | 4.47 | 6.04 | 6.04 | 8.45 | 11.0 | ||||

| 90 | 3½ | 5.27 | 6.26 | 6.26 | 8.60 | 8.60 | ||||||

| 100 | 4 | 6.80 | 8.47 | 8.47 | 11.8 | 11.8 | 14.9 | 17.7 | 21.6 | |||

| 125 | 5 | 14.3 | 14.3 | 20.4 | 20.4 | 26.5 | 32.3 | 37.8 | ||||

| 150 | 6 | 22.3 | 22.3 | 33.6 | 33.6 | 42.8 | 53.4 | 62.6 | ||||

| 200 | 8 | 35.1 | 38.8 | 44.8 | 44.8 | 56.0 | 68.1 | 68.1 | 80.0 | 95.3 | 117 | 114 |

| 250 | 10 | 55.0 | 67.2 | 79.4 | 79.4 | 107 | 107 | 126 | 151 | 175 | 227 | 204 |

| 300 | 12 | 78.5 | 103 | 117 | 126 | 172 | 154 | 209 | 252 | 295 | 377 | 295 |

| 350 | 14 | 125 | 150 | 150 | 174 | 234 | 198 | 292 | 359 | 414 | 519 | |

| 400 | 16 | 164 | 196 | 196 | 260 | 337 | 260 | 429 | 517 | 604 | 770 | |

| 450 | 18 | 208 | 290 | 249 | 369 | 488 | 330 | 604 | 734 | 862 | 1089 | |

| 500 | 20 | 309 | 409 | 309 | 483 | 653 | 409 | 819 | 1005 | 1163 | 1487 | |

| 550 | 22 | 374 | 496 | 374 | 852 | 496 | 1083 | 1307 | 1526 | 1947 | ||

| 600 | 24 | 446 | 663 | 446 | 807 | 1123 | 591 | 1397 | 1731 | 2023 | 2554 | |

| 650 | 26 | 694 | 523 | 694 | ||||||||

| 700 | 28 | 806 | 1004 | 608 | 806 | |||||||

| 750 | 30 | 927 | 1154 | 699 | 927 | |||||||

| 800 | 32 | 1056 | 1315 | 796 | 1445 | 1056 | ||||||

| 850 | 34 | 1194 | 1487 | 899 | 1634 | 1194 | ||||||

| 900 | 36 | 1338 | 1667 | 1008 | 1993 | 1338 | ||||||

| 950 | 38 | 1124 | 1493 | |||||||||

| 1000 | 40 | 1246 | 1655 | |||||||||

| 1050 | 42 | 1374 | 1826 | |||||||||

| 1100 | 44 | 1509 | 2006 | |||||||||

| 1150 | 46 | 1649 | 2191 | |||||||||

| 1200 | 48 | 1797 | 2388 |