Size Range: 1/2" - 80" / DN15 - 2000

Thickness Schedule: SCH 10 - SCH 160, XXS

Standard: ANSI / ASME B16.9 / MSS SP 43

Size Range: 1/2" - 80" / DN15 - 2000

Thickness Schedule: SCH 10 - SCH 160, XXS

Standard: ANSI / ASME B16.9 / MSS SP 43

Size Range: 1/2" - 48" / DN15 - 1200

Thickness Schedule: SCH 10 - SCH 160, XXS

Standard: ANSI / ASME B16.9

We are a manufacturer, supplier and exporter of ASME B16.9 butt weld equal and reducing tee in China.

ANSI / ASME B16.9 steel pipe tee dimensions and weight chart is free for you.

Shape Type: Equal and Reducing

Size Range: 1/2" - 80" / DN15 - 2000

Thickness Schedule: SCH 10 - SCH 160, XXS

Standard: ANSI / ASME B16.9

Type: Long Pattern (LP) and Short Pattern (SP)

Size Range: 1/2” - 24” / DN15 - 600

Thickness Schedule: SCH 10 - SCH 160, XXS

Size Range: 3/4" - 60" / DN20 - 1500

Thickness Schedule: SCH 10 - SCH 160, XXS

Standard: ANSI / ASME B16.9 / MSS SP 43

Size Range: 3/4" - 60" / DN20 - 1500

Thickness Schedule: SCH 10 - SCH 160, XXS

Standard: ANSI / ASME B16.9 & MSS SP-43

Size Range: 1/2" - 48" / DN15 - 1200

Thickness Schedule: SCH 10 - SCH 160, XXS

Standard: ANSI / ASME B16.9

Type: 90 Degree and 45 Degree

Shape: Straight and Reducing Elbow

Size: 1/8” – 4” / DN6 - DN100

Shape: Equal and Reducing Tee

Size: 1/8"- 4" / DN6 - DN100

Pressure: Class 3000LBS, 6000Lbs, 9000lbs.

Standard: ASME B16.11, BS3799

Shape: Equal Cross Tee and Reducing Cross Tee

Size Range: 1/8” – 4” / DN6 - DN100

Pressure Rating: Class 3000lbs, 6000lbs, 9000lbs.

Standard: GB/T 14383, ASME B16.11, BS3799

Type: Full Coupling and Half Coupling

Shape: Straight Coupling and Reducing Coupling

Size Range: 1/8” – 4” / DN6 - DN100

Pressure Rating: Class 3000lbs, 6000lbs, 9000lbs

Size Range: 1/8” - 3” / DN6 - DN80

Pressure Rating: Class 3000lbs

Standard: MSS SP-83

Type: 90 Degree and 45 Degree Elbow

Shape: Straight and Reducing Elbow

Thread Type: NPT, PT, BSPP, BSPT, PF

Shape: Equal and Reducing Tee

Size Range: 1/8” – 4” / DN6 - DN100

Pressure Rating: Class 2000 lbs, 3000 lbs, 6000 lbs

Shape: Equal and Reducing

Size: 1/8" - 4" / DN6 - DN100

Pressure: Class 2000 lbs, 3000 lbs, 6000 lbs

Type: Full and Half Coupling

Shape: Straight and Reducing Coupling

Thread Type: NPT, PT, BSPP, BSPT, PF

Size Range: 1/8” – 4” / DN6 - DN100

Pressure Rating: Class 3000lbs, 6000lbs

Standard: ASME B16.11, BS3799, EN 10241

Size Range: 1/8” - 3” / DN6 - DN80

Pressure Rating: Class 3000lbs

Standard: MSS SP-83

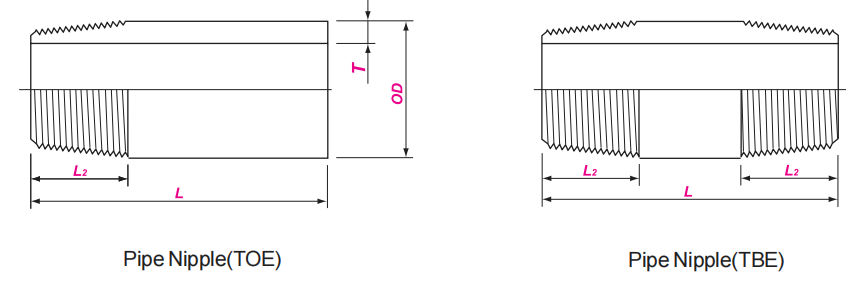

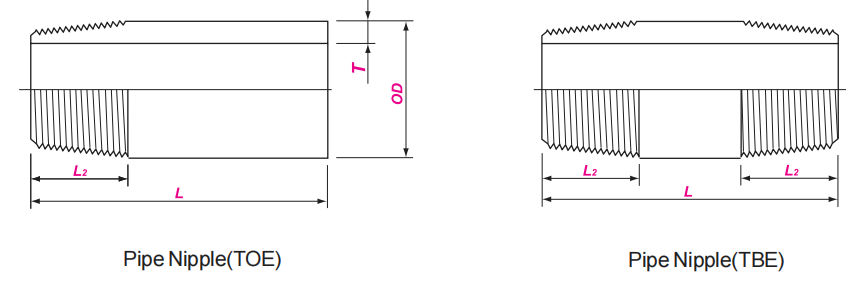

Shape: Threaded One End (TOE) and Threaded Both End (TBE)

Size : 1/4” - 12” / DN8 - DN300

Thickness : Sch 10 - Sch 160 / XXS

Shape: Concentric and Eccentric

Size: 1/4" - 12" / DN8 - DN300

Thickness: Sch 10 - Sch 160 / XXS

Shape: Equal and Reducing

Thread Type: NPT, PT, BSPP, BSPT, PF

Size Range: 1/8” - 3” / DN6 - DN80

Shape: Hex Head, Square Head and Round Head.

Thread Type: NPT, PT, BSPP, BSPT, PF

Size Range: 1/8" - 4" / DN6 - DN100

| Availability: | |

|---|---|

| Quantity: | |

What is NPT Threaded Pipe Nipple

NPT threaded pipe nipple is a short piece of pipe usually with external/male threads in both ends or in one end for connecting two other pipes or fittings. The threads at two ends can be the same or different types, such as NPT thread.

In addition, NPT threaded pipe nipple is one of the most popular categories of pipe fittings, a combination of pipe nipples is recommended for low-pressure discharge and suction service for various compatible liquids and not for compressible products like air, nitrogen, or steam.

And the length of the nipple is usually specified by the total length of the threaded portion. Moreover, it may have a hexagonal section in the center for a wrench to grasp (which is called hex nipple), or it may simply make from a piece of straight pipe (which is called barrel nipple or pipe nipple). When the nipple ends are of two different sizes it is called a reducer or unequal nipple, and threads used on nipples are BSP, BSPT, NPT, NPSM, and Metric.

What is NPT Thread

NPT stands for National Pipe Thread and is an American standard thread. It may also be refered to as MPT , MNPT or NPT (M) for male external threads and FPT, FNPT or NPT(F) for female internal threads. A thread sealant must always be used to achieve a leak free seal (except for NPTF).

Specification of ASME B16.11 Threaded Nipple

Diameter | 1/8″, 1/4″, 3/8″, 1/2″, 3/4″, 1″, 1 1/4″, 1 1/2″, 2″, 2 1/2″, 3″, 4″ |

Thickness | STD, SCH 40, SCH 80, SCH 160, XXS |

End Type | TBE, TOE, Male, Female |

Thread Type | NPT, BSPP, BSPT, PF, PT |

Surface | Anti-rust Oil, Galvanized or PE Coated. |

ASTM A105, A694 F52, F60, F65, F70, A350 LF2, LF3 | |

Alloy Steel: | ASTM A182 F1, F5, F9, F11, F12, F22, F91 |

Stainless Steel: | ASTM A182 F304/304L, F304H, F316/316L, F310, F317, F321 |

Duplex Steel: | ASTM A182 F51, F53, F55, F60 |

ASTM A733 Threaded Pipe Nipple Dimensions

| Nominal Size | OD of Pipes | Lengths of Thread | Wall of pipes | Pipe Nipple Lengths | |||

| DN | NPS | OD | L 2 min | T | L | ||

| Ⅰ | Ⅱ | Ⅲ | |||||

| 6 | 1/8 | 10.3 | 6.7 | STD,XS Sch40,Sch80 | 50 | 75 | 100 |

| 8 | 1/4 | 13.7 | 10.2 | ||||

| 10 | 3/8 | 17.1 | 10.4 | ||||

| 15 | 1/2 | 21.3 | 13.6 | STD,XS Sch40,Sch80 | 50 | 75 | 100 |

| 50 | 3/4 | 26.7 | 13.9 | ||||

| 25 | 1 | 33.4 | 17.3 | ||||

| 32 | 11/4 | 42.2 | 18.0 | STD,XS Sch40,Sch80 | 75 | 100 | 150 |

| 40 | 11/2 | 48.3 | 18.4 | ||||

| 50 | 2 | 60.3 | 19.2 | ||||

| 65 | 21/2 | 73.0 | 28.9 | STD,XS Sch40,Sch80 | 100 | 150 | 200 |

| 80 | 3 | 88.9 | 30.5 | ||||

| 90 | 31/2 | 101.6 | 31.8 | ||||

| 100 | 4 | 114.3 | 33.0 | STD,XS Sch40,Sch80 | 100 | 150 | 200 |

| 125 | 5 | 141.3 | 35.7 | ||||

| 150 | 6 | 168.3 | 38.4 | ||||

| 200 | 8 | 219.1 | 43.5 | STD,XS Sch40,Sch80 | 150 | 200 | 250 |

| 250 | 10 | 273.0 | 48.9 | ||||

| 300 | 12 | 323.8 | 54.0 | ||||

DN | NPS | SCH80 | SCH160 |

6 | 1/8 | 0.02 | 0.02 |

8 | 1/4 | 0.03 | 0.04 |

10 | 3/8 | 0.05 | 0.06 |

15 | 1/2 | 0.1 | 0.12 |

20 | 3/4 | 0.13 | 0.17 |

25 | 1 | 0.22 | 0.29 |

32 | 1 1/4 | 0.34 | 0.41 |

40 | 1 1/2 | 0.47 | 0.58 |

50 | 2 | 0.69 | 0.91 |

65 | 2 1/2 | 1.35 | 1.69 |

80 | 3 | 2.03 | 2.55 |

What are the types of Threaded Nipple?

TOE Threaded Nipple

The TOE threaded nipple is threaded only on one end, and the other end is plain or socketed, which is used to connect pipes that need to be threaded on one end. This structure makes it have specific connection uses in pipeline systems. For example, when a device with an internal thread interface needs to be connected to a pipeline, the unthreaded end of the TOE threaded nipple can be welded to the pipeline or connected in other ways, while the threaded end is threaded with the internal thread interface of the equipment.

TBE Threaded Nipple

The TBE ASME B16.11 threaded nipple has threads at both ends, which can connect pipes or pipe fittings that need to be threaded at both ends. This makes it more flexible in pipeline connection. The TBE threaded nipple can be used directly to connect two pipes with external threads, or to connect a pipe with external threads and a device or pipe fitting with internal threads.

Advantage of Pipe Nipple

NPT threaded pipe nipple play an important role in both plumbing and industrial area. Since they are short lengths of pipe with specific end connections such as threaded both ends, threaded one end, etc., they extend or redirect the flow of a system (fluid and gas). The pipe nipple is designed to connect with other fittings or pipes and is available in several alloys, sizes and shapes.

Application

Chemical processing industries

Pharmaceutical

Shipbuilding/Marine

Machine building

Architectural

What is NPT Threaded Pipe Nipple

NPT threaded pipe nipple is a short piece of pipe usually with external/male threads in both ends or in one end for connecting two other pipes or fittings. The threads at two ends can be the same or different types, such as NPT thread.

In addition, NPT threaded pipe nipple is one of the most popular categories of pipe fittings, a combination of pipe nipples is recommended for low-pressure discharge and suction service for various compatible liquids and not for compressible products like air, nitrogen, or steam.

And the length of the nipple is usually specified by the total length of the threaded portion. Moreover, it may have a hexagonal section in the center for a wrench to grasp (which is called hex nipple), or it may simply make from a piece of straight pipe (which is called barrel nipple or pipe nipple). When the nipple ends are of two different sizes it is called a reducer or unequal nipple, and threads used on nipples are BSP, BSPT, NPT, NPSM, and Metric.

What is NPT Thread

NPT stands for National Pipe Thread and is an American standard thread. It may also be refered to as MPT , MNPT or NPT (M) for male external threads and FPT, FNPT or NPT(F) for female internal threads. A thread sealant must always be used to achieve a leak free seal (except for NPTF).

Specification of ASME B16.11 Threaded Nipple

Diameter | 1/8″, 1/4″, 3/8″, 1/2″, 3/4″, 1″, 1 1/4″, 1 1/2″, 2″, 2 1/2″, 3″, 4″ |

Thickness | STD, SCH 40, SCH 80, SCH 160, XXS |

End Type | TBE, TOE, Male, Female |

Thread Type | NPT, BSPP, BSPT, PF, PT |

Surface | Anti-rust Oil, Galvanized or PE Coated. |

ASTM A105, A694 F52, F60, F65, F70, A350 LF2, LF3 | |

Alloy Steel: | ASTM A182 F1, F5, F9, F11, F12, F22, F91 |

Stainless Steel: | ASTM A182 F304/304L, F304H, F316/316L, F310, F317, F321 |

Duplex Steel: | ASTM A182 F51, F53, F55, F60 |

ASTM A733 Threaded Pipe Nipple Dimensions

| Nominal Size | OD of Pipes | Lengths of Thread | Wall of pipes | Pipe Nipple Lengths | |||

| DN | NPS | OD | L 2 min | T | L | ||

| Ⅰ | Ⅱ | Ⅲ | |||||

| 6 | 1/8 | 10.3 | 6.7 | STD,XS Sch40,Sch80 | 50 | 75 | 100 |

| 8 | 1/4 | 13.7 | 10.2 | ||||

| 10 | 3/8 | 17.1 | 10.4 | ||||

| 15 | 1/2 | 21.3 | 13.6 | STD,XS Sch40,Sch80 | 50 | 75 | 100 |

| 50 | 3/4 | 26.7 | 13.9 | ||||

| 25 | 1 | 33.4 | 17.3 | ||||

| 32 | 11/4 | 42.2 | 18.0 | STD,XS Sch40,Sch80 | 75 | 100 | 150 |

| 40 | 11/2 | 48.3 | 18.4 | ||||

| 50 | 2 | 60.3 | 19.2 | ||||

| 65 | 21/2 | 73.0 | 28.9 | STD,XS Sch40,Sch80 | 100 | 150 | 200 |

| 80 | 3 | 88.9 | 30.5 | ||||

| 90 | 31/2 | 101.6 | 31.8 | ||||

| 100 | 4 | 114.3 | 33.0 | STD,XS Sch40,Sch80 | 100 | 150 | 200 |

| 125 | 5 | 141.3 | 35.7 | ||||

| 150 | 6 | 168.3 | 38.4 | ||||

| 200 | 8 | 219.1 | 43.5 | STD,XS Sch40,Sch80 | 150 | 200 | 250 |

| 250 | 10 | 273.0 | 48.9 | ||||

| 300 | 12 | 323.8 | 54.0 | ||||

DN | NPS | SCH80 | SCH160 |

6 | 1/8 | 0.02 | 0.02 |

8 | 1/4 | 0.03 | 0.04 |

10 | 3/8 | 0.05 | 0.06 |

15 | 1/2 | 0.1 | 0.12 |

20 | 3/4 | 0.13 | 0.17 |

25 | 1 | 0.22 | 0.29 |

32 | 1 1/4 | 0.34 | 0.41 |

40 | 1 1/2 | 0.47 | 0.58 |

50 | 2 | 0.69 | 0.91 |

65 | 2 1/2 | 1.35 | 1.69 |

80 | 3 | 2.03 | 2.55 |

What are the types of Threaded Nipple?

TOE Threaded Nipple

The TOE threaded nipple is threaded only on one end, and the other end is plain or socketed, which is used to connect pipes that need to be threaded on one end. This structure makes it have specific connection uses in pipeline systems. For example, when a device with an internal thread interface needs to be connected to a pipeline, the unthreaded end of the TOE threaded nipple can be welded to the pipeline or connected in other ways, while the threaded end is threaded with the internal thread interface of the equipment.

TBE Threaded Nipple

The TBE ASME B16.11 threaded nipple has threads at both ends, which can connect pipes or pipe fittings that need to be threaded at both ends. This makes it more flexible in pipeline connection. The TBE threaded nipple can be used directly to connect two pipes with external threads, or to connect a pipe with external threads and a device or pipe fitting with internal threads.

Advantage of Pipe Nipple

NPT threaded pipe nipple play an important role in both plumbing and industrial area. Since they are short lengths of pipe with specific end connections such as threaded both ends, threaded one end, etc., they extend or redirect the flow of a system (fluid and gas). The pipe nipple is designed to connect with other fittings or pipes and is available in several alloys, sizes and shapes.

Application

Chemical processing industries

Pharmaceutical

Shipbuilding/Marine

Machine building

Architectural