Size Range: 1/2" - 80" / DN15 - 2000

Thickness Schedule: SCH 10 - SCH 160, XXS

Standard: ANSI / ASME B16.9 / MSS SP 43

Size Range: 1/2" - 80" / DN15 - 2000

Thickness Schedule: SCH 10 - SCH 160, XXS

Standard: ANSI / ASME B16.9 / MSS SP 43

Size Range: 1/2" - 48" / DN15 - 1200

Thickness Schedule: SCH 10 - SCH 160, XXS

Standard: ANSI / ASME B16.9

We are a manufacturer, supplier and exporter of ASME B16.9 butt weld equal and reducing tee in China.

ANSI / ASME B16.9 steel pipe tee dimensions and weight chart is free for you.

Shape Type: Equal and Reducing

Size Range: 1/2" - 80" / DN15 - 2000

Thickness Schedule: SCH 10 - SCH 160, XXS

Standard: ANSI / ASME B16.9

Type: Long Pattern (LP) and Short Pattern (SP)

Size Range: 1/2” - 24” / DN15 - 600

Thickness Schedule: SCH 10 - SCH 160, XXS

Size Range: 3/4" - 60" / DN20 - 1500

Thickness Schedule: SCH 10 - SCH 160, XXS

Standard: ANSI / ASME B16.9 / MSS SP 43

Size Range: 3/4" - 60" / DN20 - 1500

Thickness Schedule: SCH 10 - SCH 160, XXS

Standard: ANSI / ASME B16.9 & MSS SP-43

Size Range: 1/2" - 48" / DN15 - 1200

Thickness Schedule: SCH 10 - SCH 160, XXS

Standard: ANSI / ASME B16.9

Type: 90 Degree and 45 Degree

Shape: Straight and Reducing Elbow

Size: 1/8” – 4” / DN6 - DN100

Shape: Equal and Reducing Tee

Size: 1/8"- 4" / DN6 - DN100

Pressure: Class 3000LBS, 6000Lbs, 9000lbs.

Standard: ASME B16.11, BS3799

Shape: Equal Cross Tee and Reducing Cross Tee

Size Range: 1/8” – 4” / DN6 - DN100

Pressure Rating: Class 3000lbs, 6000lbs, 9000lbs.

Standard: GB/T 14383, ASME B16.11, BS3799

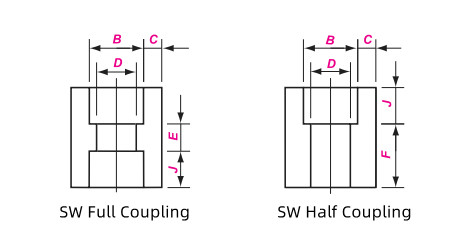

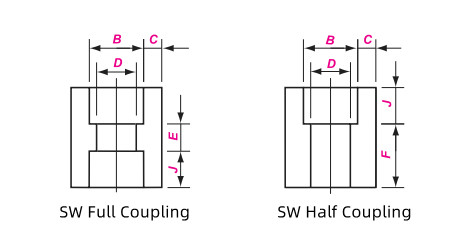

Type: Full Coupling and Half Coupling

Shape: Straight Coupling and Reducing Coupling

Size Range: 1/8” – 4” / DN6 - DN100

Pressure Rating: Class 3000lbs, 6000lbs, 9000lbs

Size Range: 1/8” - 3” / DN6 - DN80

Pressure Rating: Class 3000lbs

Standard: MSS SP-83

Type: 90 Degree and 45 Degree Elbow

Shape: Straight and Reducing Elbow

Thread Type: NPT, PT, BSPP, BSPT, PF

Shape: Equal and Reducing Tee

Size Range: 1/8” – 4” / DN6 - DN100

Pressure Rating: Class 2000 lbs, 3000 lbs, 6000 lbs

Shape: Equal and Reducing

Size: 1/8" - 4" / DN6 - DN100

Pressure: Class 2000 lbs, 3000 lbs, 6000 lbs

Type: Full and Half Coupling

Shape: Straight and Reducing Coupling

Thread Type: NPT, PT, BSPP, BSPT, PF

Size Range: 1/8” – 4” / DN6 - DN100

Pressure Rating: Class 3000lbs, 6000lbs

Standard: ASME B16.11, BS3799, EN 10241

Size Range: 1/8” - 3” / DN6 - DN80

Pressure Rating: Class 3000lbs

Standard: MSS SP-83

Shape: Threaded One End (TOE) and Threaded Both End (TBE)

Size : 1/4” - 12” / DN8 - DN300

Thickness : Sch 10 - Sch 160 / XXS

Shape: Concentric and Eccentric

Size: 1/4" - 12" / DN8 - DN300

Thickness: Sch 10 - Sch 160 / XXS

Shape: Equal and Reducing

Thread Type: NPT, PT, BSPP, BSPT, PF

Size Range: 1/8” - 3” / DN6 - DN80

Shape: Hex Head, Square Head and Round Head.

Thread Type: NPT, PT, BSPP, BSPT, PF

Size Range: 1/8" - 4" / DN6 - DN100

Type: Full Coupling and Half Coupling

Shape: Straight Coupling and Reducing Coupling

Size Range: 1/8” – 4” / DN6 - DN100

Pressure Rating: Class 3000lbs, 6000lbs, 9000lbs

| Availability: | |

|---|---|

| Quantity: | |

Socket weld coupling is a short piece of pipe with socket bore at end, which is manufactured in acordance to forged steel fittings of ASME B16.11. Couplings are used to help extend or terminate runs and to change pipe sizes and are designed to provide good flow characteristics. We supplied many A105 carbon steel and 316 stainless steel socket weld fittings to customers.

Socket Weld Fittings are a family of high pressure forging fittings that used only in conjunction with ANSI Pipe and are available in the same size range.Even though there are some similarities between the shapes of the two welds, but socket weld is still considered to be different from a fillet weld.

How Many Types of Socket Weld Coupling

Straight Coupling

Reducing Coupling

Socket Weld Full Coupling

Socket Weld Half Coupling

Carbon Steel Socket Weld Coupling

Stainless Steel Socket Weld Coupling

Specification of ASME B16.11 & BS3799 Socket Weld Fittings

| Type | Elbow, Tee, Cross, Coupling, Cap, Lateral |

| Shape | Straight and Reducing Fittings |

| Size Range | 1/8" - 4" / DN6 - DN100 |

| Pressure Rating | Class 3000lbs, 6000lbs, 9000lbs |

| Carbon Steel | ASTM A105 / A105N, A350 LF2/LF3, ASTM A694 F42 / F46 / F56 / F60 / F65 |

| Alloy Steel | ASTM A182 F5 / F9 / F11 / F12 / F22 / F91 / F92 |

| Stainless Steel | ASTM A182 F304/304L/304H, F316/316L, F321, F310S, F317, F347, F904L |

| Duplex Stainless Steel | ASTM A182 F51, F53, F44 |

ASME B16.11 Socket Weld Coupling Dimensions

DN | NPS | B | D | C | |||||||

| 3000 | 6000 | 9000 | 3000 | 6000 | 9000 | ||||||

| 6 | 1/8 | 10.9 | 6.1 | 3.2 | - | 3.18 | 3.18 | 3.96 | 3.43 | - | - |

| 8 | 1/4 | 14.3 | 8.5 | 5.6 | - | 3.78 | 3.30 | 4.60 | 4.01 | - | - |

| 10 | 3/8 | 17.7 | 11.8 | 8.4 | - | 4.01 | 3.50 | 5.03 | 4.37 | - | - |

| 15 | 1/2 | 21.9 | 15.0 | 11.0 | 5.6 | 4.67 | 4.09 | 5.97 | 5.18 | 9.53 | 8.18 |

| 20 | 3/4 | 27.3 | 20.2 | 14.8 | 10.3 | 4.90 | 4.27 | 6.96 | 6.04 | 9.78 | 8.56 |

| 25 | 1 | 34.0 | 25.9 | 19.9 | 14.4 | 5.69 | 4.98 | 7.92 | 6.93 | 11.38 | 9.96 |

| 32 | 11/4 | 42.8 | 34.3 | 28.7 | 22.0 | 6.07 | 5.28 | 7.92 | 6.93 | 12.14 | 10.62 |

| 40 | 11/2 | 48.9 | 40.1 | 33.2 | 27.2 | 6.35 | 5.54 | 8.92 | 7.80 | 12.7 | 11.12 |

| 50 | 2 | 61.2 | 51.7 | 42.1 | 37.4 | 6.93 | 6.04 | 10.92 | 9.50 | 13.84 | 12.12 |

| 65 | 21/2 | 73.9 | 61.2 | - | - | 8.76 | 7.62 | - | - | - | - |

| 80 | 3 | 89.9 | 76.4 | - | - | 9.52 | 8.30 | - | - | - | - |

| 100 | 4 | 115.5 | 100.7 | - | - | 10.69 | 9.35 | - | - | - | - |

1) The even thickness around the socket bore shall not be less than the average value, the thickness at partial areas can be the min. one.

2) Considering the tolerance of outside diameter of pipe, the diameters of some socket bore can be a little larger than the ones specified in ASME B16.11.

3) When the sizes of the connecting pipes aren t conformed to the ones specified in this catalog, the sizes of the connecting pipes shall be provided in the purchase specification.

4) When the fittings are reducing,the structure sizes shall be same as the ones of the straight fittings and B J D shall be machined per the according reducing ends.

5) Fittings can also be manufactured as the mixed connectings of SW and THRD.

Socket Weld Coupling Weight Chart in kg

| DN | NPS | 3000 | 6000 | 9000 |

| 6 | 1/8 | 0.05 | 0.06 | - |

| 8 | 1/4 | 0.06 | 0.07 | - |

| 10 | 3/8 | 0.08 | 0.10 | - |

| 15 | 1/2 | 0.13 | 0.16 | 0.29 |

| 20 | 3/4 | 0.20 | 0.28 | 0.47 |

| 25 | 1 | 0.28 | 0.48 | 0.68 |

| 32 | 1-1/4 | 0.48 | 0.65 | 1.08 |

| 40 | 1-1/2 | 0.52 | 0.94 | 1.12 |

| 50 | 2 | 0.95 | 1.65 | 1.95 |

| 65 | 2-1/2 | 1.52 | - | - |

| 80 | 3 | 1.75 | - | - |

| 100 | 4 | 2.8 | - | - |

Socket weld coupling is a short piece of pipe with socket bore at end, which is manufactured in acordance to forged steel fittings of ASME B16.11. Couplings are used to help extend or terminate runs and to change pipe sizes and are designed to provide good flow characteristics. We supplied many A105 carbon steel and 316 stainless steel socket weld fittings to customers.

Socket Weld Fittings are a family of high pressure forging fittings that used only in conjunction with ANSI Pipe and are available in the same size range.Even though there are some similarities between the shapes of the two welds, but socket weld is still considered to be different from a fillet weld.

How Many Types of Socket Weld Coupling

Straight Coupling

Reducing Coupling

Socket Weld Full Coupling

Socket Weld Half Coupling

Carbon Steel Socket Weld Coupling

Stainless Steel Socket Weld Coupling

Specification of ASME B16.11 & BS3799 Socket Weld Fittings

| Type | Elbow, Tee, Cross, Coupling, Cap, Lateral |

| Shape | Straight and Reducing Fittings |

| Size Range | 1/8" - 4" / DN6 - DN100 |

| Pressure Rating | Class 3000lbs, 6000lbs, 9000lbs |

| Carbon Steel | ASTM A105 / A105N, A350 LF2/LF3, ASTM A694 F42 / F46 / F56 / F60 / F65 |

| Alloy Steel | ASTM A182 F5 / F9 / F11 / F12 / F22 / F91 / F92 |

| Stainless Steel | ASTM A182 F304/304L/304H, F316/316L, F321, F310S, F317, F347, F904L |

| Duplex Stainless Steel | ASTM A182 F51, F53, F44 |

ASME B16.11 Socket Weld Coupling Dimensions

DN | NPS | B | D | C | |||||||

| 3000 | 6000 | 9000 | 3000 | 6000 | 9000 | ||||||

| 6 | 1/8 | 10.9 | 6.1 | 3.2 | - | 3.18 | 3.18 | 3.96 | 3.43 | - | - |

| 8 | 1/4 | 14.3 | 8.5 | 5.6 | - | 3.78 | 3.30 | 4.60 | 4.01 | - | - |

| 10 | 3/8 | 17.7 | 11.8 | 8.4 | - | 4.01 | 3.50 | 5.03 | 4.37 | - | - |

| 15 | 1/2 | 21.9 | 15.0 | 11.0 | 5.6 | 4.67 | 4.09 | 5.97 | 5.18 | 9.53 | 8.18 |

| 20 | 3/4 | 27.3 | 20.2 | 14.8 | 10.3 | 4.90 | 4.27 | 6.96 | 6.04 | 9.78 | 8.56 |

| 25 | 1 | 34.0 | 25.9 | 19.9 | 14.4 | 5.69 | 4.98 | 7.92 | 6.93 | 11.38 | 9.96 |

| 32 | 11/4 | 42.8 | 34.3 | 28.7 | 22.0 | 6.07 | 5.28 | 7.92 | 6.93 | 12.14 | 10.62 |

| 40 | 11/2 | 48.9 | 40.1 | 33.2 | 27.2 | 6.35 | 5.54 | 8.92 | 7.80 | 12.7 | 11.12 |

| 50 | 2 | 61.2 | 51.7 | 42.1 | 37.4 | 6.93 | 6.04 | 10.92 | 9.50 | 13.84 | 12.12 |

| 65 | 21/2 | 73.9 | 61.2 | - | - | 8.76 | 7.62 | - | - | - | - |

| 80 | 3 | 89.9 | 76.4 | - | - | 9.52 | 8.30 | - | - | - | - |

| 100 | 4 | 115.5 | 100.7 | - | - | 10.69 | 9.35 | - | - | - | - |

1) The even thickness around the socket bore shall not be less than the average value, the thickness at partial areas can be the min. one.

2) Considering the tolerance of outside diameter of pipe, the diameters of some socket bore can be a little larger than the ones specified in ASME B16.11.

3) When the sizes of the connecting pipes aren t conformed to the ones specified in this catalog, the sizes of the connecting pipes shall be provided in the purchase specification.

4) When the fittings are reducing,the structure sizes shall be same as the ones of the straight fittings and B J D shall be machined per the according reducing ends.

5) Fittings can also be manufactured as the mixed connectings of SW and THRD.

Socket Weld Coupling Weight Chart in kg

| DN | NPS | 3000 | 6000 | 9000 |

| 6 | 1/8 | 0.05 | 0.06 | - |

| 8 | 1/4 | 0.06 | 0.07 | - |

| 10 | 3/8 | 0.08 | 0.10 | - |

| 15 | 1/2 | 0.13 | 0.16 | 0.29 |

| 20 | 3/4 | 0.20 | 0.28 | 0.47 |

| 25 | 1 | 0.28 | 0.48 | 0.68 |

| 32 | 1-1/4 | 0.48 | 0.65 | 1.08 |

| 40 | 1-1/2 | 0.52 | 0.94 | 1.12 |

| 50 | 2 | 0.95 | 1.65 | 1.95 |

| 65 | 2-1/2 | 1.52 | - | - |

| 80 | 3 | 1.75 | - | - |

| 100 | 4 | 2.8 | - | - |