Size Range: 1/2" - 80" / DN15 - 2000

Thickness Schedule: SCH 10 - SCH 160, XXS

Standard: ANSI / ASME B16.9 / MSS SP 43

Size Range: 1/2" - 80" / DN15 - 2000

Thickness Schedule: SCH 10 - SCH 160, XXS

Standard: ANSI / ASME B16.9 / MSS SP 43

Size Range: 1/2" - 48" / DN15 - 1200

Thickness Schedule: SCH 10 - SCH 160, XXS

Standard: ANSI / ASME B16.9

We are a manufacturer, supplier and exporter of ASME B16.9 butt weld equal and reducing tee in China.

ANSI / ASME B16.9 steel pipe tee dimensions and weight chart is free for you.

Shape Type: Equal and Reducing

Size Range: 1/2" - 80" / DN15 - 2000

Thickness Schedule: SCH 10 - SCH 160, XXS

Standard: ANSI / ASME B16.9

Type: Long Pattern (LP) and Short Pattern (SP)

Size Range: 1/2” - 24” / DN15 - 600

Thickness Schedule: SCH 10 - SCH 160, XXS

Size Range: 3/4" - 60" / DN20 - 1500

Thickness Schedule: SCH 10 - SCH 160, XXS

Standard: ANSI / ASME B16.9 / MSS SP 43

Size Range: 3/4" - 60" / DN20 - 1500

Thickness Schedule: SCH 10 - SCH 160, XXS

Standard: ANSI / ASME B16.9 & MSS SP-43

Size Range: 1/2" - 48" / DN15 - 1200

Thickness Schedule: SCH 10 - SCH 160, XXS

Standard: ANSI / ASME B16.9

Type: 90 Degree and 45 Degree

Shape: Straight and Reducing Elbow

Size: 1/8” – 4” / DN6 - DN100

Shape: Equal and Reducing Tee

Size: 1/8"- 4" / DN6 - DN100

Pressure: Class 3000LBS, 6000Lbs, 9000lbs.

Standard: ASME B16.11, BS3799

Shape: Equal Cross Tee and Reducing Cross Tee

Size Range: 1/8” – 4” / DN6 - DN100

Pressure Rating: Class 3000lbs, 6000lbs, 9000lbs.

Standard: GB/T 14383, ASME B16.11, BS3799

Type: Full Coupling and Half Coupling

Shape: Straight Coupling and Reducing Coupling

Size Range: 1/8” – 4” / DN6 - DN100

Pressure Rating: Class 3000lbs, 6000lbs, 9000lbs

Size Range: 1/8” - 3” / DN6 - DN80

Pressure Rating: Class 3000lbs

Standard: MSS SP-83

Type: 90 Degree and 45 Degree Elbow

Shape: Straight and Reducing Elbow

Thread Type: NPT, PT, BSPP, BSPT, PF

Shape: Equal and Reducing Tee

Size Range: 1/8” – 4” / DN6 - DN100

Pressure Rating: Class 2000 lbs, 3000 lbs, 6000 lbs

Shape: Equal and Reducing

Size: 1/8" - 4" / DN6 - DN100

Pressure: Class 2000 lbs, 3000 lbs, 6000 lbs

Type: Full and Half Coupling

Shape: Straight and Reducing Coupling

Thread Type: NPT, PT, BSPP, BSPT, PF

Size Range: 1/8” – 4” / DN6 - DN100

Pressure Rating: Class 3000lbs, 6000lbs

Standard: ASME B16.11, BS3799, EN 10241

Size Range: 1/8” - 3” / DN6 - DN80

Pressure Rating: Class 3000lbs

Standard: MSS SP-83

| Availability: | |

|---|---|

| Quantity: | |

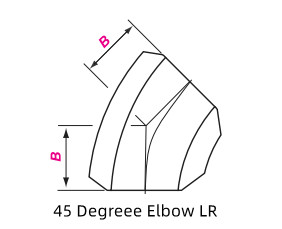

SS304/L 45 degree elbow is a key parts in a pipe system for to change the fluid flow direction. It is used to connect two pipes with same or different nominal diameters.

Butt wled elbow is mounted between two pipes so that the fluid direction can be changed to 45 degrees. 45 degree elbow can produces less friction and with the lower pressure than 90 degree.

45 degree elbow is widely used in chemical, food, water supply facilities, electronic industry, chemical pipelines, horticulture, agriculture production, solar equipment pipelines, air conditioning pipeline and other fields.

| D N | NPS | OD | B |

| LR | |||

| 15 | 1/2 | 21.3 | 16 |

| 20 | 3/4 | 26.7 | 19 |

| 25 | 1 | 33.4 | 22 |

| 32 | 1-1/4 | 42.2 | 25 |

| 40 | 1-1/2 | 48.3 | 29 |

| 50 | 2 | 60.3 | 35 |

| 65 | 2-1/2 | 73.0 | 44 |

| 80 | 3 | 88.9 | 51 |

| 90 | 3-1/2 | 101.6 | 57 |

| 100 | 4 | 114.3 | 64 |

| 125 | 5 | 141.3 | 79 |

| 150 | 6 | 168.3 | 95 |

| 200 | 8 | 219.1 | 127 |

| 250 | 10 | 273.1 | 159 |

| 300 | 12 | 323.8 | 190 |

| 350 | 14 | 355.6 | 222 |

| 400 | 16 | 406.4 | 254 |

| 450 | 18 | 457.0 | 286 |

| 500 | 20 | 508.0 | 318 |

| 550 | 22 | 559.0 | 343 |

| 600 | 24 | 609.6 | 381 |

Dimension & Weight of 45 Degree Elbow

45 Degree Long Radius steel Butt Weld Elbow (BW Elbow) Refer Standard ASME B16.9 | |||||||

Nominal | Outside | Weight (kg) | |||||

SCH 10S | SCH 20 | STD | SCH 40 | XS | SCH 80 | ||

1/2 | 21.3 | 0.03 | 0.04 | 0.04 | 0.08 | 0.08 | |

3/4 | 26.7 | 0.03 | 0.04 | 0.04 | 0.08 | 0.08 | |

1 | 33.4 | 0.09 | 0.08 | 0.08 | 0.10 | 0.10 | |

11/4 | 42.2 | 0.12 | 0.12 | 0.12 | 0.18 | 0.18 | |

11/2 | 48.3 | 0.17 | 0.18 | 0.18 | 0.25 | 0.25 | |

2 | 60.3 | 0.25 | 0.32 | 0.32 | 0.47 | 0.47 | |

21/2 | 73 | 0.48 | 0.64 | 0.64 | 0.85 | 0.85 | |

3 | 38.9 | 0.62 | 1.02 | 1.02 | 1.37 | 1.37 | |

31/2 | 101.6 | 0.76 | 1.43 | 1.43 | 1.97 | 1.97 | |

4 | 114.3 | 1.10 | 1.95 | 1.95 | 2.70 | 2.70 | |

5 | 141.3 | 1.80 | 3.25 | 3.25 | 4.42 | 4.42 | |

6 | 168.3 | 2.75 | 5.10 | 5.10 | 7.67 | 7.67 | |

8 | 219.1 | 5.30 | 9.00 | 11.15 | 11.15 | 14.95 | 14.95 |

10 | 273 | 9.80 | 18.50 | 20.50 | 20.50 | 24.30 | 30.00 |

12 | 323.8 | 13.60 | 24.75 | 27 | 29.57 | 35.00 | 49.94 |

14 | 355.6 | 18.10 | 32.00 | 34 | 39.98 | 47.17 | 69.92 |

16 | 406.4 | 23.80 | 46.50 | 48 | 62.37 | 62.37 | 102.15 |

18 | 457 | 30 | 56 | 60 | 88.53 | 79.00 | 143.92 |

20 | 508 | 50 | 71.20 | 71.20 | 114 | 97.16 | 195.67 |

22 | 559 | 89 | 89 | 118.00 | 256.70 | ||

24 | 610 | 71 | 102 | 102.95 | 192.04 | 141.20 | 333.70 |

26 | 660 | 165 | 124.90 | 165.71 | |||

28 | 711 | 202 | 150 | 202 | |||

30 | 762 | 220 | 167 | 220 | |||

32 | 813 | 255 | 193 | 344 | 255 | ||

34 | 864 | 280 | 215 | 389 | 280 | ||

36 | 914 | 312 | 241 | 476 | 312 | ||

38 | 965 | 272 | 354 | ||||

40 | 1016 | 290 | 372 | ||||

42 | 1067 | 660 | 327 | 420 | |||

44 | 1118 | 695 | 363 | 488 | |||

46 | 1168 | 727 | 408 | 530 | |||

48 | 1219 | 759 | 443 | 567 | |||

Material SS304/L

Stainless steel 90 degree elbow is a most common use of pipe elbow for stainless pipelines. Other than this is stainless steel 45 degree elbow, both of them in large requirements for butt weld, socket weld, and threaded connections.

AISI 304 stainless steel (UNS S30400) is the most widely used stainless steel, containing 18-20% Cr and 8-10.5% Ni, also known as 18-8 stainless steel. SS 304 is non-magnetic under annealing conditions, but after cold processing (such as stamping, stretching, bending, rolling), some austenite structures may transform into martensite, thus exhibiting weak magnetism. Type 304 has good resistance to atmospheric corrosion and oxidation resistance.

Application

SS304/L 45 degree elbow is non-magnetic and has high corrosion and oxidation resistance to sources in the atmospheric, chemical, petroleum, textile, and food industries. It has good stretch ability - the combination of low yield strength and high elongation allows it to be processed into complex shapes.

SS304/L 45 degree elbow is widely used in the food industry, household appliances and consumer electronics, medical equipment, building decoration,hardware tools, automotive industry, petrochemicals, water treatment plants, aerospace,etc.

Type Range

Standard | ASME B16.9, DIN2615, JIS B2312 |

Types | 45 degree steel elbow (We also provide 90,180 degree steel pipe elbow) |

Size Range | 1/2”to 48” |

Thickness | SCH10S,SCH20,SCHSTD,SCH40S,SCHXS, SCH80S,SCH160,SCHXXS |

Packing Picture

We not only focus on provide high quality goods but also pursue to offer profession service. About packing,we have different ways such as Carton & Wooden Box & Wooden Pallet & Bundled. The packing pictures of 4"/6"/8"SS304L B Elbows as below:

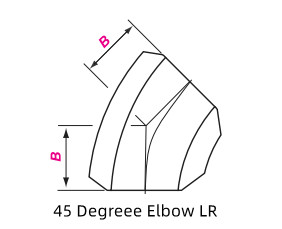

SS304/L 45 degree elbow is a key parts in a pipe system for to change the fluid flow direction. It is used to connect two pipes with same or different nominal diameters.

Butt wled elbow is mounted between two pipes so that the fluid direction can be changed to 45 degrees. 45 degree elbow can produces less friction and with the lower pressure than 90 degree.

45 degree elbow is widely used in chemical, food, water supply facilities, electronic industry, chemical pipelines, horticulture, agriculture production, solar equipment pipelines, air conditioning pipeline and other fields.

| D N | NPS | OD | B |

| LR | |||

| 15 | 1/2 | 21.3 | 16 |

| 20 | 3/4 | 26.7 | 19 |

| 25 | 1 | 33.4 | 22 |

| 32 | 1-1/4 | 42.2 | 25 |

| 40 | 1-1/2 | 48.3 | 29 |

| 50 | 2 | 60.3 | 35 |

| 65 | 2-1/2 | 73.0 | 44 |

| 80 | 3 | 88.9 | 51 |

| 90 | 3-1/2 | 101.6 | 57 |

| 100 | 4 | 114.3 | 64 |

| 125 | 5 | 141.3 | 79 |

| 150 | 6 | 168.3 | 95 |

| 200 | 8 | 219.1 | 127 |

| 250 | 10 | 273.1 | 159 |

| 300 | 12 | 323.8 | 190 |

| 350 | 14 | 355.6 | 222 |

| 400 | 16 | 406.4 | 254 |

| 450 | 18 | 457.0 | 286 |

| 500 | 20 | 508.0 | 318 |

| 550 | 22 | 559.0 | 343 |

| 600 | 24 | 609.6 | 381 |

Dimension & Weight of 45 Degree Elbow

45 Degree Long Radius steel Butt Weld Elbow (BW Elbow) Refer Standard ASME B16.9 | |||||||

Nominal | Outside | Weight (kg) | |||||

SCH 10S | SCH 20 | STD | SCH 40 | XS | SCH 80 | ||

1/2 | 21.3 | 0.03 | 0.04 | 0.04 | 0.08 | 0.08 | |

3/4 | 26.7 | 0.03 | 0.04 | 0.04 | 0.08 | 0.08 | |

1 | 33.4 | 0.09 | 0.08 | 0.08 | 0.10 | 0.10 | |

11/4 | 42.2 | 0.12 | 0.12 | 0.12 | 0.18 | 0.18 | |

11/2 | 48.3 | 0.17 | 0.18 | 0.18 | 0.25 | 0.25 | |

2 | 60.3 | 0.25 | 0.32 | 0.32 | 0.47 | 0.47 | |

21/2 | 73 | 0.48 | 0.64 | 0.64 | 0.85 | 0.85 | |

3 | 38.9 | 0.62 | 1.02 | 1.02 | 1.37 | 1.37 | |

31/2 | 101.6 | 0.76 | 1.43 | 1.43 | 1.97 | 1.97 | |

4 | 114.3 | 1.10 | 1.95 | 1.95 | 2.70 | 2.70 | |

5 | 141.3 | 1.80 | 3.25 | 3.25 | 4.42 | 4.42 | |

6 | 168.3 | 2.75 | 5.10 | 5.10 | 7.67 | 7.67 | |

8 | 219.1 | 5.30 | 9.00 | 11.15 | 11.15 | 14.95 | 14.95 |

10 | 273 | 9.80 | 18.50 | 20.50 | 20.50 | 24.30 | 30.00 |

12 | 323.8 | 13.60 | 24.75 | 27 | 29.57 | 35.00 | 49.94 |

14 | 355.6 | 18.10 | 32.00 | 34 | 39.98 | 47.17 | 69.92 |

16 | 406.4 | 23.80 | 46.50 | 48 | 62.37 | 62.37 | 102.15 |

18 | 457 | 30 | 56 | 60 | 88.53 | 79.00 | 143.92 |

20 | 508 | 50 | 71.20 | 71.20 | 114 | 97.16 | 195.67 |

22 | 559 | 89 | 89 | 118.00 | 256.70 | ||

24 | 610 | 71 | 102 | 102.95 | 192.04 | 141.20 | 333.70 |

26 | 660 | 165 | 124.90 | 165.71 | |||

28 | 711 | 202 | 150 | 202 | |||

30 | 762 | 220 | 167 | 220 | |||

32 | 813 | 255 | 193 | 344 | 255 | ||

34 | 864 | 280 | 215 | 389 | 280 | ||

36 | 914 | 312 | 241 | 476 | 312 | ||

38 | 965 | 272 | 354 | ||||

40 | 1016 | 290 | 372 | ||||

42 | 1067 | 660 | 327 | 420 | |||

44 | 1118 | 695 | 363 | 488 | |||

46 | 1168 | 727 | 408 | 530 | |||

48 | 1219 | 759 | 443 | 567 | |||

Material SS304/L

Stainless steel 90 degree elbow is a most common use of pipe elbow for stainless pipelines. Other than this is stainless steel 45 degree elbow, both of them in large requirements for butt weld, socket weld, and threaded connections.

AISI 304 stainless steel (UNS S30400) is the most widely used stainless steel, containing 18-20% Cr and 8-10.5% Ni, also known as 18-8 stainless steel. SS 304 is non-magnetic under annealing conditions, but after cold processing (such as stamping, stretching, bending, rolling), some austenite structures may transform into martensite, thus exhibiting weak magnetism. Type 304 has good resistance to atmospheric corrosion and oxidation resistance.

Application

SS304/L 45 degree elbow is non-magnetic and has high corrosion and oxidation resistance to sources in the atmospheric, chemical, petroleum, textile, and food industries. It has good stretch ability - the combination of low yield strength and high elongation allows it to be processed into complex shapes.

SS304/L 45 degree elbow is widely used in the food industry, household appliances and consumer electronics, medical equipment, building decoration,hardware tools, automotive industry, petrochemicals, water treatment plants, aerospace,etc.

Type Range

Standard | ASME B16.9, DIN2615, JIS B2312 |

Types | 45 degree steel elbow (We also provide 90,180 degree steel pipe elbow) |

Size Range | 1/2”to 48” |

Thickness | SCH10S,SCH20,SCHSTD,SCH40S,SCHXS, SCH80S,SCH160,SCHXXS |

Packing Picture

We not only focus on provide high quality goods but also pursue to offer profession service. About packing,we have different ways such as Carton & Wooden Box & Wooden Pallet & Bundled. The packing pictures of 4"/6"/8"SS304L B Elbows as below: