Size Range: 1/2" - 80" / DN15 - 2000

Thickness Schedule: SCH 10 - SCH 160, XXS

Standard: ANSI / ASME B16.9 / MSS SP 43

Size Range: 1/2" - 80" / DN15 - 2000

Thickness Schedule: SCH 10 - SCH 160, XXS

Standard: ANSI / ASME B16.9 / MSS SP 43

Size Range: 1/2" - 48" / DN15 - 1200

Thickness Schedule: SCH 10 - SCH 160, XXS

Standard: ANSI / ASME B16.9

We are a manufacturer, supplier and exporter of ASME B16.9 butt weld equal and reducing tee in China.

ANSI / ASME B16.9 steel pipe tee dimensions and weight chart is free for you.

Shape Type: Equal and Reducing

Size Range: 1/2" - 80" / DN15 - 2000

Thickness Schedule: SCH 10 - SCH 160, XXS

Standard: ANSI / ASME B16.9

Type: Long Pattern (LP) and Short Pattern (SP)

Size Range: 1/2” - 24” / DN15 - 600

Thickness Schedule: SCH 10 - SCH 160, XXS

Size Range: 3/4" - 60" / DN20 - 1500

Thickness Schedule: SCH 10 - SCH 160, XXS

Standard: ANSI / ASME B16.9 / MSS SP 43

Size Range: 3/4" - 60" / DN20 - 1500

Thickness Schedule: SCH 10 - SCH 160, XXS

Standard: ANSI / ASME B16.9 & MSS SP-43

Size Range: 1/2" - 48" / DN15 - 1200

Thickness Schedule: SCH 10 - SCH 160, XXS

Standard: ANSI / ASME B16.9

Type: 90 Degree and 45 Degree

Shape: Straight and Reducing Elbow

Size: 1/8” – 4” / DN6 - DN100

Shape: Equal and Reducing Tee

Size: 1/8"- 4" / DN6 - DN100

Pressure: Class 3000LBS, 6000Lbs, 9000lbs.

Standard: ASME B16.11, BS3799

Shape: Equal Cross Tee and Reducing Cross Tee

Size Range: 1/8” – 4” / DN6 - DN100

Pressure Rating: Class 3000lbs, 6000lbs, 9000lbs.

Standard: GB/T 14383, ASME B16.11, BS3799

Type: Full Coupling and Half Coupling

Shape: Straight Coupling and Reducing Coupling

Size Range: 1/8” – 4” / DN6 - DN100

Pressure Rating: Class 3000lbs, 6000lbs, 9000lbs

Size Range: 1/8” - 3” / DN6 - DN80

Pressure Rating: Class 3000lbs

Standard: MSS SP-83

Type: 90 Degree and 45 Degree Elbow

Shape: Straight and Reducing Elbow

Thread Type: NPT, PT, BSPP, BSPT, PF

Shape: Equal and Reducing Tee

Size Range: 1/8” – 4” / DN6 - DN100

Pressure Rating: Class 2000 lbs, 3000 lbs, 6000 lbs

Shape: Equal and Reducing

Size: 1/8" - 4" / DN6 - DN100

Pressure: Class 2000 lbs, 3000 lbs, 6000 lbs

Type: Full and Half Coupling

Shape: Straight and Reducing Coupling

Thread Type: NPT, PT, BSPP, BSPT, PF

Size Range: 1/8” – 4” / DN6 - DN100

Pressure Rating: Class 3000lbs, 6000lbs

Standard: ASME B16.11, BS3799, EN 10241

Size Range: 1/8” - 3” / DN6 - DN80

Pressure Rating: Class 3000lbs

Standard: MSS SP-83

Shape: Threaded One End (TOE) and Threaded Both End (TBE)

Size : 1/4” - 12” / DN8 - DN300

Thickness : Sch 10 - Sch 160 / XXS

Shape: Concentric and Eccentric

Size: 1/4" - 12" / DN8 - DN300

Thickness: Sch 10 - Sch 160 / XXS

Shape: Equal and Reducing

Thread Type: NPT, PT, BSPP, BSPT, PF

Size Range: 1/8” - 3” / DN6 - DN80

Shape: Hex Head, Square Head and Round Head.

Thread Type: NPT, PT, BSPP, BSPT, PF

Size Range: 1/8" - 4" / DN6 - DN100

| Availability: | |

|---|---|

| Quantity: | |

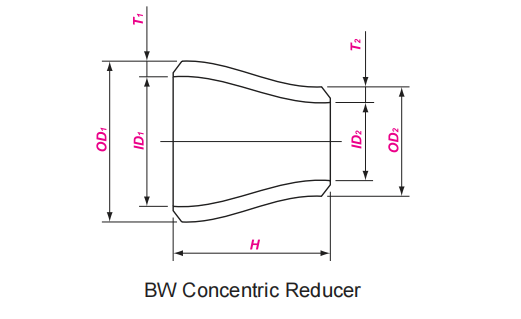

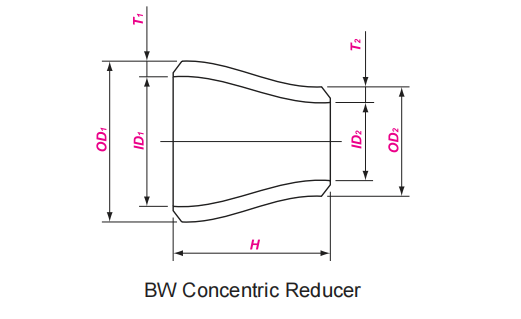

Manufacturing Standard of Concentric Reducer

Standard have relation to the process of butt weld fittings includes ASME/ANSI B16.9, ASME B16.28, MSS-SP-43. ASME/ANSI B16.9 is the standard for all the weld fittings that are wrought butt welded and are produced in factories with the size that range from NPS 1/2"to NPS 48", it is evaluated from MSS-SP-43, which is the standard for stainless steel and alloy steel fittings.

ASME B16.9 concentric reducer is a component in a piping system that changes the pipe size from a larger to a smaller bore. Butt weld concentric reducer is used in various applications that involved in high pressure, vibration & temperature. They are widely used in chemical, petroleum, shipbuilding, gas, power sectors.

So for the requirement in the newest version, we should have apply ASME B16.9 concentric reducer.

Dimensions and Weight of ASME B16.9 Concentric Reducer

Due to the change in size and thickness, the dimension must be different in each end of the reducer. When we calculate the weight, which data should we do the estimate on? The answer is basing on the larger data, for example, we have a ASME B16.9 concentric reduce in size of 5" X 4", thickness of SCH 80 X SCH40, due to the manufacturing process, the larger end usually with a smaller thickness, we need to refer to data 5 inches and SCH80 to have the weight.

NPS | O.D. | O.D. | Length |

D | D1 | H | |

3/4 - 1/2 | 26.7 | 21.3 | 38 |

1-1/2 | 33.4 | 21.3 | 51 |

1-3/4 | 33.4 | 26.7 | 51 |

1.1/4 - 1/2 | 42.2 | 21.3 | 51 |

1.1/4 - 3/4 | 42.2 | 26.7 | 51 |

1.1/4 - 1 | 42.2 | 33.4 | 51 |

1.1/2 - 1/2 | 48.3 | 21.3 | 64 |

1.1/2 - 3/4 | 48.3 | 26.7 | 64 |

1.1/2 - 1 | 48.3 | 33.4 | 64 |

1.1/2 - 1.1/4 | 48.3 | 42.2 | 64 |

2-3/4 | 60.3 | 26.7 | 76 |

2-1 | 60.3 | 33.4 | 76 |

2 - 1.1/4 | 60.3 | 42.2 | 76 |

2 - 1.1/2 | 60.3 | 48.3 | 76 |

2.1/2 - 1 | 73 | 33.4 | 89 |

2.1/2 - 1.1/4 | 73 | 42.2 | 89 |

2.1/2 - 1.1/2 | 73 | 48.3 | 89 |

2.1/2 - 2 | 73 | 60.3 | 89 |

3 - 1.1/4 | 88.9 | 42.2 | 89 |

3 - 1.1/2 | 88.9 | 48.3 | 89 |

3-2 | 88.9 | 60.3 | 89 |

3 - 2.1/2 | 88.9 | 73 | 89 |

3.1/2 - 1.1/4 | 101.6 | 42.2 | 102 |

3.1/2 - 1.1/2 | 101.6 | 48.3 | 102 |

3.1/2 - 2 | 101.6 | 60.3 | 102 |

3.1/2 - 2.1/2 | 101.6 | 73 | 102 |

3.1/2 - 3 | 101.6 | 88.9 | 102 |

4 - 1.1/2 | 114.3 | 48.3 | 102 |

4-2 | 114.3 | 60.3 | 102 |

4 - 2.1/2 | 114.3 | 73 | 102 |

4-3 | 114.3 | 88.9 | 102 |

4 - 3.1/2 | 114.3 | 101.6 | 102 |

5-2 | 141.3 | 60.3 | 127 |

5 - 2.1/2 | 141.3 | 73 | 127 |

5-3 | 141.3 | 88.9 | 127 |

5 - 3.1/2 | 141.3 | 101.6 | 127 |

5-4 | 141.3 | 114.3 | 127 |

6 - 2.1/2 | 168.3 | 73 | 140 |

6-3 | 168.3 | 88.9 | 140 |

6 - 3.1/2 | 168.3 | 101.6 | 140 |

6-4 | 168.3 | 114.3 | 140 |

6-5 | 168.3 | 141.3 | 140 |

8 - 3.1/2 | 219.1 | 101.6 | 152 |

8-4 | 219.1 | 114.3 | 152 |

8-5 | 219.1 | 141.3 | 152 |

8-6 | 219.1 | 168.3 | 152 |

10-4 | 273 | 114.3 | 178 |

10-5 | 273 | 141.3 | 178 |

10-6 | 273 | 168.3 | 178 |

10-8 | 273 | 219.1 | 178 |

12-5 | 323.9 | 141.3 | 203 |

12-6 | 323.9 | 168.3 | 203 |

12-8 | 323.9 | 219.1 | 203 |

12-10 | 323.9 | 273 | 203 |

14-6 | 355.6 | 168.3 | 330 |

14-8 | 355.6 | 219.1 | 330 |

14-10 | 355.6 | 273 | 330 |

14-12 | 355.6 | 323.9 | 330 |

16-8 | 406.4 | 219 | 356 |

16-10 | 406.4 | 273 | 356 |

16-12 | 406.4 | 323.9 | 356 |

16 - 14 | 406.4 | 355.6 | 356 |

18-10 | 457 | 273 | 381 |

18-12 | 457 | 323.9 | 381 |

18 - 14 | 457 | 355.6 | 381 |

18 - 16 | 457 | 406.4 | 381 |

45646 | 508 | 323.9 | 508 |

20 - 14 | 508 | 355.6 | 508 |

20 - 16 | 508 | 406.4 | 508 |

20 - 18 | 508 | 457 | 508 |

22 - 14 | 559 | 355.6 | 508 |

22 - 16 | 559 | 406.4 | 508 |

22 - 18 | 559 | 457 | 508 |

22 - 20 | 559 | 508 | 508 |

24 - 16 | 610 | 406.4 | 508 |

24 - 18 | 610 | 457 | 508 |

24 - 20 | 610 | 508 | 508 |

24 - 22 | 610 | 559 | 508 |

26 - 18 | 660 | 457 | 610 |

26 - 20 | 660 | 508 | 610 |

26 - 22 | 660 | 559 | 610 |

26 - 24 | 660 | 610 | 610 |

28 - 18 | 711 | 457 | 610 |

28 - 20 | 711 | 508 | 610 |

28 - 24 | 711 | 610 | 610 |

28 - 26 | 711 | 660 | 610 |

30 - 20 | 762 | 508 | 610 |

30 - 24 | 762 | 610 | 610 |

30 - 26 | 762 | 660 | 610 |

30 - 28 | 762 | 711 | 610 |

32 - 24 | 813 | 610 | 610 |

32 - 26 | 813 | 660 | 610 |

32 - 28 | 813 | 711 | 610 |

32 - 30 | 813 | 762 | 610 |

34 - 24 | 864 | 610 | 610 |

34 - 26 | 864 | 660 | 610 |

34 - 30 | 864 | 762 | 610 |

34 - 32 | 864 | 813 | 610 |

36 - 24 | 914 | 610 | 610 |

36 - 26 | 914 | 660 | 610 |

36 - 30 | 914 | 762 | 610 |

36 - 32 | 914 | 813 | 610 |

36 - 34 | 914 | 864 | 610 |

38 - 26 | 965 | 660 | 610 |

38 - 28 | 965 | 711 | 610 |

38 - 30 | 965 | 762 | 610 |

38 - 32 | 965 | 813 | 610 |

38 - 34 | 965 | 864 | 610 |

38 - 36 | 965 | 914 | 610 |

40 - 30 | 1016 | 762 | 610 |

40 - 32 | 1016 | 813 | 610 |

40 - 34 | 1016 | 864 | 610 |

40 - 36 | 1016 | 914 | 610 |

40 - 38 | 1016 | 965 | 6 |

Material of Concentric Reducer

The main type of the butt weld fittings is A234/A420/A403/A860, under that requirement their are many different grade stand for different material type. For example WPB standard for carbon steel, WP9 is a kind of low alloy steel.

Carbon steel | ASTM A234 WPB; |

Low temperature steel | A420 WPL3/6/9; |

Pipeline steel | A860 WPHY 42/46/52/56/60/65/70; |

Alloy steel | A234 WP5/9/11/12/22/91/92; |

Stainless Steel | A403 WP304/316/317/310S/321/347/904L |

Usage of Concentric Reducer

Energy industries

Fluid piping

Home appliances

Heat exchangerOil and gas industry

Pulp and paper industry

Power plants

Pharmaceutical processing industry

Synthetic fiberTextile machinery

Manufacturing Standard of Concentric Reducer

Standard have relation to the process of butt weld fittings includes ASME/ANSI B16.9, ASME B16.28, MSS-SP-43. ASME/ANSI B16.9 is the standard for all the weld fittings that are wrought butt welded and are produced in factories with the size that range from NPS 1/2"to NPS 48", it is evaluated from MSS-SP-43, which is the standard for stainless steel and alloy steel fittings.

ASME B16.9 concentric reducer is a component in a piping system that changes the pipe size from a larger to a smaller bore. Butt weld concentric reducer is used in various applications that involved in high pressure, vibration & temperature. They are widely used in chemical, petroleum, shipbuilding, gas, power sectors.

So for the requirement in the newest version, we should have apply ASME B16.9 concentric reducer.

Dimensions and Weight of ASME B16.9 Concentric Reducer

Due to the change in size and thickness, the dimension must be different in each end of the reducer. When we calculate the weight, which data should we do the estimate on? The answer is basing on the larger data, for example, we have a ASME B16.9 concentric reduce in size of 5" X 4", thickness of SCH 80 X SCH40, due to the manufacturing process, the larger end usually with a smaller thickness, we need to refer to data 5 inches and SCH80 to have the weight.

NPS | O.D. | O.D. | Length |

D | D1 | H | |

3/4 - 1/2 | 26.7 | 21.3 | 38 |

1-1/2 | 33.4 | 21.3 | 51 |

1-3/4 | 33.4 | 26.7 | 51 |

1.1/4 - 1/2 | 42.2 | 21.3 | 51 |

1.1/4 - 3/4 | 42.2 | 26.7 | 51 |

1.1/4 - 1 | 42.2 | 33.4 | 51 |

1.1/2 - 1/2 | 48.3 | 21.3 | 64 |

1.1/2 - 3/4 | 48.3 | 26.7 | 64 |

1.1/2 - 1 | 48.3 | 33.4 | 64 |

1.1/2 - 1.1/4 | 48.3 | 42.2 | 64 |

2-3/4 | 60.3 | 26.7 | 76 |

2-1 | 60.3 | 33.4 | 76 |

2 - 1.1/4 | 60.3 | 42.2 | 76 |

2 - 1.1/2 | 60.3 | 48.3 | 76 |

2.1/2 - 1 | 73 | 33.4 | 89 |

2.1/2 - 1.1/4 | 73 | 42.2 | 89 |

2.1/2 - 1.1/2 | 73 | 48.3 | 89 |

2.1/2 - 2 | 73 | 60.3 | 89 |

3 - 1.1/4 | 88.9 | 42.2 | 89 |

3 - 1.1/2 | 88.9 | 48.3 | 89 |

3-2 | 88.9 | 60.3 | 89 |

3 - 2.1/2 | 88.9 | 73 | 89 |

3.1/2 - 1.1/4 | 101.6 | 42.2 | 102 |

3.1/2 - 1.1/2 | 101.6 | 48.3 | 102 |

3.1/2 - 2 | 101.6 | 60.3 | 102 |

3.1/2 - 2.1/2 | 101.6 | 73 | 102 |

3.1/2 - 3 | 101.6 | 88.9 | 102 |

4 - 1.1/2 | 114.3 | 48.3 | 102 |

4-2 | 114.3 | 60.3 | 102 |

4 - 2.1/2 | 114.3 | 73 | 102 |

4-3 | 114.3 | 88.9 | 102 |

4 - 3.1/2 | 114.3 | 101.6 | 102 |

5-2 | 141.3 | 60.3 | 127 |

5 - 2.1/2 | 141.3 | 73 | 127 |

5-3 | 141.3 | 88.9 | 127 |

5 - 3.1/2 | 141.3 | 101.6 | 127 |

5-4 | 141.3 | 114.3 | 127 |

6 - 2.1/2 | 168.3 | 73 | 140 |

6-3 | 168.3 | 88.9 | 140 |

6 - 3.1/2 | 168.3 | 101.6 | 140 |

6-4 | 168.3 | 114.3 | 140 |

6-5 | 168.3 | 141.3 | 140 |

8 - 3.1/2 | 219.1 | 101.6 | 152 |

8-4 | 219.1 | 114.3 | 152 |

8-5 | 219.1 | 141.3 | 152 |

8-6 | 219.1 | 168.3 | 152 |

10-4 | 273 | 114.3 | 178 |

10-5 | 273 | 141.3 | 178 |

10-6 | 273 | 168.3 | 178 |

10-8 | 273 | 219.1 | 178 |

12-5 | 323.9 | 141.3 | 203 |

12-6 | 323.9 | 168.3 | 203 |

12-8 | 323.9 | 219.1 | 203 |

12-10 | 323.9 | 273 | 203 |

14-6 | 355.6 | 168.3 | 330 |

14-8 | 355.6 | 219.1 | 330 |

14-10 | 355.6 | 273 | 330 |

14-12 | 355.6 | 323.9 | 330 |

16-8 | 406.4 | 219 | 356 |

16-10 | 406.4 | 273 | 356 |

16-12 | 406.4 | 323.9 | 356 |

16 - 14 | 406.4 | 355.6 | 356 |

18-10 | 457 | 273 | 381 |

18-12 | 457 | 323.9 | 381 |

18 - 14 | 457 | 355.6 | 381 |

18 - 16 | 457 | 406.4 | 381 |

45646 | 508 | 323.9 | 508 |

20 - 14 | 508 | 355.6 | 508 |

20 - 16 | 508 | 406.4 | 508 |

20 - 18 | 508 | 457 | 508 |

22 - 14 | 559 | 355.6 | 508 |

22 - 16 | 559 | 406.4 | 508 |

22 - 18 | 559 | 457 | 508 |

22 - 20 | 559 | 508 | 508 |

24 - 16 | 610 | 406.4 | 508 |

24 - 18 | 610 | 457 | 508 |

24 - 20 | 610 | 508 | 508 |

24 - 22 | 610 | 559 | 508 |

26 - 18 | 660 | 457 | 610 |

26 - 20 | 660 | 508 | 610 |

26 - 22 | 660 | 559 | 610 |

26 - 24 | 660 | 610 | 610 |

28 - 18 | 711 | 457 | 610 |

28 - 20 | 711 | 508 | 610 |

28 - 24 | 711 | 610 | 610 |

28 - 26 | 711 | 660 | 610 |

30 - 20 | 762 | 508 | 610 |

30 - 24 | 762 | 610 | 610 |

30 - 26 | 762 | 660 | 610 |

30 - 28 | 762 | 711 | 610 |

32 - 24 | 813 | 610 | 610 |

32 - 26 | 813 | 660 | 610 |

32 - 28 | 813 | 711 | 610 |

32 - 30 | 813 | 762 | 610 |

34 - 24 | 864 | 610 | 610 |

34 - 26 | 864 | 660 | 610 |

34 - 30 | 864 | 762 | 610 |

34 - 32 | 864 | 813 | 610 |

36 - 24 | 914 | 610 | 610 |

36 - 26 | 914 | 660 | 610 |

36 - 30 | 914 | 762 | 610 |

36 - 32 | 914 | 813 | 610 |

36 - 34 | 914 | 864 | 610 |

38 - 26 | 965 | 660 | 610 |

38 - 28 | 965 | 711 | 610 |

38 - 30 | 965 | 762 | 610 |

38 - 32 | 965 | 813 | 610 |

38 - 34 | 965 | 864 | 610 |

38 - 36 | 965 | 914 | 610 |

40 - 30 | 1016 | 762 | 610 |

40 - 32 | 1016 | 813 | 610 |

40 - 34 | 1016 | 864 | 610 |

40 - 36 | 1016 | 914 | 610 |

40 - 38 | 1016 | 965 | 6 |

Material of Concentric Reducer

The main type of the butt weld fittings is A234/A420/A403/A860, under that requirement their are many different grade stand for different material type. For example WPB standard for carbon steel, WP9 is a kind of low alloy steel.

Carbon steel | ASTM A234 WPB; |

Low temperature steel | A420 WPL3/6/9; |

Pipeline steel | A860 WPHY 42/46/52/56/60/65/70; |

Alloy steel | A234 WP5/9/11/12/22/91/92; |

Stainless Steel | A403 WP304/316/317/310S/321/347/904L |

Usage of Concentric Reducer

Energy industries

Fluid piping

Home appliances

Heat exchangerOil and gas industry

Pulp and paper industry

Power plants

Pharmaceutical processing industry

Synthetic fiberTextile machinery