Size Range: 1/2" - 80" / DN15 - 2000

Thickness Schedule: SCH 10 - SCH 160, XXS

Standard: ANSI / ASME B16.9 / MSS SP 43

Size Range: 1/2" - 80" / DN15 - 2000

Thickness Schedule: SCH 10 - SCH 160, XXS

Standard: ANSI / ASME B16.9 / MSS SP 43

Size Range: 1/2" - 48" / DN15 - 1200

Thickness Schedule: SCH 10 - SCH 160, XXS

Standard: ANSI / ASME B16.9

We are a manufacturer, supplier and exporter of ASME B16.9 butt weld equal and reducing tee in China.

ANSI / ASME B16.9 steel pipe tee dimensions and weight chart is free for you.

Shape Type: Equal and Reducing

Size Range: 1/2" - 80" / DN15 - 2000

Thickness Schedule: SCH 10 - SCH 160, XXS

Standard: ANSI / ASME B16.9

Type: Long Pattern (LP) and Short Pattern (SP)

Size Range: 1/2” - 24” / DN15 - 600

Thickness Schedule: SCH 10 - SCH 160, XXS

Size Range: 3/4" - 60" / DN20 - 1500

Thickness Schedule: SCH 10 - SCH 160, XXS

Standard: ANSI / ASME B16.9 / MSS SP 43

Size Range: 3/4" - 60" / DN20 - 1500

Thickness Schedule: SCH 10 - SCH 160, XXS

Standard: ANSI / ASME B16.9 & MSS SP-43

Size Range: 1/2" - 48" / DN15 - 1200

Thickness Schedule: SCH 10 - SCH 160, XXS

Standard: ANSI / ASME B16.9

Type: 90 Degree and 45 Degree

Shape: Straight and Reducing Elbow

Size: 1/8” – 4” / DN6 - DN100

Shape: Equal and Reducing Tee

Size: 1/8"- 4" / DN6 - DN100

Pressure: Class 3000LBS, 6000Lbs, 9000lbs.

Standard: ASME B16.11, BS3799

Shape: Equal Cross Tee and Reducing Cross Tee

Size Range: 1/8” – 4” / DN6 - DN100

Pressure Rating: Class 3000lbs, 6000lbs, 9000lbs.

Standard: GB/T 14383, ASME B16.11, BS3799

Type: Full Coupling and Half Coupling

Shape: Straight Coupling and Reducing Coupling

Size Range: 1/8” – 4” / DN6 - DN100

Pressure Rating: Class 3000lbs, 6000lbs, 9000lbs

Size Range: 1/8” - 3” / DN6 - DN80

Pressure Rating: Class 3000lbs

Standard: MSS SP-83

Type: 90 Degree and 45 Degree Elbow

Shape: Straight and Reducing Elbow

Thread Type: NPT, PT, BSPP, BSPT, PF

Shape: Equal and Reducing Tee

Size Range: 1/8” – 4” / DN6 - DN100

Pressure Rating: Class 2000 lbs, 3000 lbs, 6000 lbs

Shape: Equal and Reducing

Size: 1/8" - 4" / DN6 - DN100

Pressure: Class 2000 lbs, 3000 lbs, 6000 lbs

Type: Full and Half Coupling

Shape: Straight and Reducing Coupling

Thread Type: NPT, PT, BSPP, BSPT, PF

Size Range: 1/8” – 4” / DN6 - DN100

Pressure Rating: Class 3000lbs, 6000lbs

Standard: ASME B16.11, BS3799, EN 10241

Size Range: 1/8” - 3” / DN6 - DN80

Pressure Rating: Class 3000lbs

Standard: MSS SP-83

Shape: Threaded One End (TOE) and Threaded Both End (TBE)

Size : 1/4” - 12” / DN8 - DN300

Thickness : Sch 10 - Sch 160 / XXS

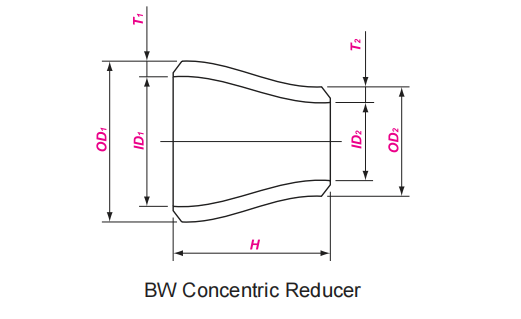

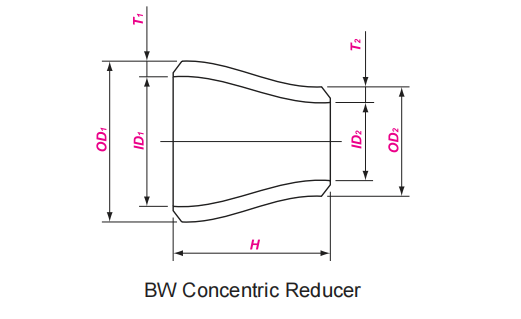

Shape: Concentric and Eccentric

Size: 1/4" - 12" / DN8 - DN300

Thickness: Sch 10 - Sch 160 / XXS

Shape: Equal and Reducing

Thread Type: NPT, PT, BSPP, BSPT, PF

Size Range: 1/8” - 3” / DN6 - DN80

Shape: Hex Head, Square Head and Round Head.

Thread Type: NPT, PT, BSPP, BSPT, PF

Size Range: 1/8" - 4" / DN6 - DN100

| Availability: | |

|---|---|

| Quantity: | |

What does “ASTM A234 WPB Concentric Reducer “Stand for

ASTM A234 WPB concentric reducer is a kind of pipe connecting fittings used to connect two pipe ends in different size, and the connection type of the ends should be in butt weld type. Basing on whether the center axis is in the same horizontal line line or not, it can be divided into concentric and eccentric two different types.

ASTM A234 is the standard specification of butt weld fitting materials include alloys steel and carbon steel, WPB is the the most commonly used carbon steel grade in the system. The standard covers general requirement of killed steel, forgings, bars, plates, seamless or fusion-welded tubular products with filler metal added.

Material of A234 WPB

Material standard of each kind of material standard includes the requirement for chemicals, mechanicals, heat treatment, surface treatment and so on.

Chemical composition

CHEMICAL | LIMITS | C | Mn | P | S | Si | Cr | Mo | Ni | Cu | V |

ASTM A234 WPB | MIN | 0.29 | 0.10 | ||||||||

MAX | 0.30 | 1.06 | 0.050 | 0.058 | 0.40 | 0.15 | 0.40 | 0.40 | 0.08 |

Mechanical Properties

MATERIAL | T.S (MPA) | Y.S (MPA) | EL % | R/A % |

ASTM A234 WPB | 415 min | 240 min | 22 min | 30 min |

ASME B16.9 Concentric Reducer Dimensions

OD1 | OD2 | END TO END | SCH 40 WEIGHT |

NPS | NPS | H | KG |

3/4 | 3/8 - 1/2 | 38 | 0.07 |

1 | 1/2 - 3/4 | 51 | 0.14 |

1 1/4 | 1/2 - 1 | 51 | 0.19 |

1 1/2 | 1/2 - 1 1/4 | 64 | 0.29 |

2 | 3/4 - 1 1/2 | 76 | 0.46 |

2 1/2 | 1 - 2 | 89 | 0.85 |

3 | 1 1/4 - 2 1/2 | 102 | 1.11 |

4 | 2 - 3 1/2 | 102 | 1.8 |

5 | 2 - 4 | 127 | 3.05 |

6 | 2 1/2 - 5 | 140 | 4.35 |

8 | 3 1/2 - 6 | 152 | 7.12 |

10 | 4 - 8 | 178 | 11.8 |

12 | 5 - 10 | 203 | 17.8 |

14 | 6 - 12 | 330 | 34.3 |

16 | 6 - 14 | 356 | 48.3 |

18 | 8 - 16 | 381 | 65.3 |

20 | 10 - 18 | 508 | 102 |

22 | 12 - 20 | 508 | - |

24 | 12 - 22 | 508 | 143 |

26 | 12 - 24 | 610 | - |

28 | 14 - 26 | 610 | - |

30 | 14 - 28 | 610 | - |

32 | 20 - 30 | 610 | 230 |

34 | 22 - 32 | 610 | 245 |

36 | 22 - 34 | 610 | 282 |

38 | 24 - 36 | 610 | - |

40 | 28 - 38 | 610 | - |

42 | 28 - 40 | 610 | - |

44 | 32 - 42 | 610 | - |

46 | 34 - 44 | 711 | - |

48 | 36 - 46 | 711 | - |

52 | 40 - 48 | 711 | - |

56 | 40 - 52 | 711 | - |

60 | 44 - 56 | 711 | - |

Weight List of Concentric Reducer

Please notice the two ends of the reducer may have different thickness schedule, when you judge the weight to calculate the cost for sea or land freight, please be sure you choose the larger schedule number to avoid insufficient budget.

Large End | Sch20 | Sch30 | STD | Sch40 | Sch60 | XS | Sch80 | Sch100 | Sch120 | Sch160 | XXS | |

Norminal Size | ||||||||||||

D N | NPS | |||||||||||

20 | 3/4 |

| 0.06 | 0.07 | 0.07 |

| 0.09 | 0.09 |

|

| 0.12 | 0.15 |

25 | 1 |

| 0.12 | 0.14 | 0.14 |

| 0.18 | 0.18 |

|

| 0.24 | 0.31 |

32 | 1-1/4 |

| 0.16 | 0.19 | 0.19 |

| 0.25 | 0.25 |

|

| 0.32 | 0.45 |

40 | 1-1/2 |

| 0.25 | 0.29 | 0.29 |

| 0.38 | 0.38 |

|

| 0.51 | 0.7 |

50 | 2 |

| 0.37 | 0.46 | 0.46 |

| 0.63 | 0.63 |

|

| 0.93 | 1.2 |

62 | 2-1/2 |

| 0.79 | 0.85 | 0.85 |

| 1.12 | 1.12 |

|

| 1.46 | 2 |

80 | 3 |

| 0.97 | 1.11 | 1.11 |

| 1.5 | 1.5 |

| - | 2.09 | 2.71 |

90 | 3-1/2 |

| 1.28 | 1.52 | 1.52 |

| 2.09 | 2.09 |

| - | - | - |

100 | 4 |

| 1.45 | 1.81 | 1.81 |

| 2.51 | 2.5 |

| 3.18 | 3.76 | 4.6 |

125 | 5 | - | - | 3.04 | 3.04 | - | 4.33 | 4.33 | - | 5.63 | 6.86 | 8.02 |

250 | 10 | 8.18 | 9.99 | 11.8 | 11.8 | 16 | 16 | 18.8 | 22.5 | 26 | 33.7 | 30.4 |

300 | 12 | 11.1 | 14.6 | 16.5 | 17.8 | 24.3 | 21.8 | 29.5 | 35.7 | 41.7 | 53.3 | 41.7 |

350 | 14 | 24.6 | 29.5 | 29.6 | 34.3 | 46 | 39 | 57.4 | 70.8 | 81.5 | 102 | - |

400 | 16 | 30.5 | 36.5 | 36.6 | 48.3 | 62.7 | 48.3 | 79.7 | 96.2 | 112 | 143 |

|

450 | 18 | 36.8 | 51.3 | 44.1 | 65.3 | 86.2 | 58.3 | 107 | 130 | 152 | 193 |

|

500 | 20 | 65.5 | 86.7 | 65.5 | 102 | 138 | 86.7 | 174 | 213 | 152 | 193 |

|

550 | 22 | 72.2 | 95.6 | 72.2 | - | 164 | 95.6 | 209 | 252 | 294 | 376 |

|

600 | 24 | 78.9 | 117 | 78.9 | 143 | 199 | 105 | 247 | 306 | 358 | 452 |

|

Difference Between Concentric Reducer and Eccentric Reducer

Concentric Reducer

Eccentric Reducer

Different from eccentric reducer, a concentric reducer keep their center line in the same center line. ASTM A234 WPB concentric reducers, they decrease the outer diameter of the pipe ends at a stable ate over one certain length, to reduce the pipe size and keep the pipes system symmetrical at the same time. Eccentric reducers are usually used on the flat surface on the ground because it is more easy to place the pipes on the track.

Advantages of ASME B16.9 Reducer

As a commonly used connection component in the pipeline system, ASTM A234 WPB reducer have many advantages.

●Good sealing performance

The reducers are connected to the steel pipe by welding to form a complete sealing structure.

●High pressure rating

Its compact structure and high strength can withstand large internal pressure and external force, ensuring that the pipeline system can maintain stable operation under various working conditions.

What does “ASTM A234 WPB Concentric Reducer “Stand for

ASTM A234 WPB concentric reducer is a kind of pipe connecting fittings used to connect two pipe ends in different size, and the connection type of the ends should be in butt weld type. Basing on whether the center axis is in the same horizontal line line or not, it can be divided into concentric and eccentric two different types.

ASTM A234 is the standard specification of butt weld fitting materials include alloys steel and carbon steel, WPB is the the most commonly used carbon steel grade in the system. The standard covers general requirement of killed steel, forgings, bars, plates, seamless or fusion-welded tubular products with filler metal added.

Material of A234 WPB

Material standard of each kind of material standard includes the requirement for chemicals, mechanicals, heat treatment, surface treatment and so on.

Chemical composition

CHEMICAL | LIMITS | C | Mn | P | S | Si | Cr | Mo | Ni | Cu | V |

ASTM A234 WPB | MIN | 0.29 | 0.10 | ||||||||

MAX | 0.30 | 1.06 | 0.050 | 0.058 | 0.40 | 0.15 | 0.40 | 0.40 | 0.08 |

Mechanical Properties

MATERIAL | T.S (MPA) | Y.S (MPA) | EL % | R/A % |

ASTM A234 WPB | 415 min | 240 min | 22 min | 30 min |

ASME B16.9 Concentric Reducer Dimensions

OD1 | OD2 | END TO END | SCH 40 WEIGHT |

NPS | NPS | H | KG |

3/4 | 3/8 - 1/2 | 38 | 0.07 |

1 | 1/2 - 3/4 | 51 | 0.14 |

1 1/4 | 1/2 - 1 | 51 | 0.19 |

1 1/2 | 1/2 - 1 1/4 | 64 | 0.29 |

2 | 3/4 - 1 1/2 | 76 | 0.46 |

2 1/2 | 1 - 2 | 89 | 0.85 |

3 | 1 1/4 - 2 1/2 | 102 | 1.11 |

4 | 2 - 3 1/2 | 102 | 1.8 |

5 | 2 - 4 | 127 | 3.05 |

6 | 2 1/2 - 5 | 140 | 4.35 |

8 | 3 1/2 - 6 | 152 | 7.12 |

10 | 4 - 8 | 178 | 11.8 |

12 | 5 - 10 | 203 | 17.8 |

14 | 6 - 12 | 330 | 34.3 |

16 | 6 - 14 | 356 | 48.3 |

18 | 8 - 16 | 381 | 65.3 |

20 | 10 - 18 | 508 | 102 |

22 | 12 - 20 | 508 | - |

24 | 12 - 22 | 508 | 143 |

26 | 12 - 24 | 610 | - |

28 | 14 - 26 | 610 | - |

30 | 14 - 28 | 610 | - |

32 | 20 - 30 | 610 | 230 |

34 | 22 - 32 | 610 | 245 |

36 | 22 - 34 | 610 | 282 |

38 | 24 - 36 | 610 | - |

40 | 28 - 38 | 610 | - |

42 | 28 - 40 | 610 | - |

44 | 32 - 42 | 610 | - |

46 | 34 - 44 | 711 | - |

48 | 36 - 46 | 711 | - |

52 | 40 - 48 | 711 | - |

56 | 40 - 52 | 711 | - |

60 | 44 - 56 | 711 | - |

Weight List of Concentric Reducer

Please notice the two ends of the reducer may have different thickness schedule, when you judge the weight to calculate the cost for sea or land freight, please be sure you choose the larger schedule number to avoid insufficient budget.

Large End | Sch20 | Sch30 | STD | Sch40 | Sch60 | XS | Sch80 | Sch100 | Sch120 | Sch160 | XXS | |

Norminal Size | ||||||||||||

D N | NPS | |||||||||||

20 | 3/4 |

| 0.06 | 0.07 | 0.07 |

| 0.09 | 0.09 |

|

| 0.12 | 0.15 |

25 | 1 |

| 0.12 | 0.14 | 0.14 |

| 0.18 | 0.18 |

|

| 0.24 | 0.31 |

32 | 1-1/4 |

| 0.16 | 0.19 | 0.19 |

| 0.25 | 0.25 |

|

| 0.32 | 0.45 |

40 | 1-1/2 |

| 0.25 | 0.29 | 0.29 |

| 0.38 | 0.38 |

|

| 0.51 | 0.7 |

50 | 2 |

| 0.37 | 0.46 | 0.46 |

| 0.63 | 0.63 |

|

| 0.93 | 1.2 |

62 | 2-1/2 |

| 0.79 | 0.85 | 0.85 |

| 1.12 | 1.12 |

|

| 1.46 | 2 |

80 | 3 |

| 0.97 | 1.11 | 1.11 |

| 1.5 | 1.5 |

| - | 2.09 | 2.71 |

90 | 3-1/2 |

| 1.28 | 1.52 | 1.52 |

| 2.09 | 2.09 |

| - | - | - |

100 | 4 |

| 1.45 | 1.81 | 1.81 |

| 2.51 | 2.5 |

| 3.18 | 3.76 | 4.6 |

125 | 5 | - | - | 3.04 | 3.04 | - | 4.33 | 4.33 | - | 5.63 | 6.86 | 8.02 |

250 | 10 | 8.18 | 9.99 | 11.8 | 11.8 | 16 | 16 | 18.8 | 22.5 | 26 | 33.7 | 30.4 |

300 | 12 | 11.1 | 14.6 | 16.5 | 17.8 | 24.3 | 21.8 | 29.5 | 35.7 | 41.7 | 53.3 | 41.7 |

350 | 14 | 24.6 | 29.5 | 29.6 | 34.3 | 46 | 39 | 57.4 | 70.8 | 81.5 | 102 | - |

400 | 16 | 30.5 | 36.5 | 36.6 | 48.3 | 62.7 | 48.3 | 79.7 | 96.2 | 112 | 143 |

|

450 | 18 | 36.8 | 51.3 | 44.1 | 65.3 | 86.2 | 58.3 | 107 | 130 | 152 | 193 |

|

500 | 20 | 65.5 | 86.7 | 65.5 | 102 | 138 | 86.7 | 174 | 213 | 152 | 193 |

|

550 | 22 | 72.2 | 95.6 | 72.2 | - | 164 | 95.6 | 209 | 252 | 294 | 376 |

|

600 | 24 | 78.9 | 117 | 78.9 | 143 | 199 | 105 | 247 | 306 | 358 | 452 |

|

Difference Between Concentric Reducer and Eccentric Reducer

Concentric Reducer

Eccentric Reducer

Different from eccentric reducer, a concentric reducer keep their center line in the same center line. ASTM A234 WPB concentric reducers, they decrease the outer diameter of the pipe ends at a stable ate over one certain length, to reduce the pipe size and keep the pipes system symmetrical at the same time. Eccentric reducers are usually used on the flat surface on the ground because it is more easy to place the pipes on the track.

Advantages of ASME B16.9 Reducer

As a commonly used connection component in the pipeline system, ASTM A234 WPB reducer have many advantages.

●Good sealing performance

The reducers are connected to the steel pipe by welding to form a complete sealing structure.

●High pressure rating

Its compact structure and high strength can withstand large internal pressure and external force, ensuring that the pipeline system can maintain stable operation under various working conditions.