Size Range: 1/2" - 80" / DN15 - 2000

Thickness Schedule: SCH 10 - SCH 160, XXS

Standard: ANSI / ASME B16.9 / MSS SP 43

Size Range: 1/2" - 80" / DN15 - 2000

Thickness Schedule: SCH 10 - SCH 160, XXS

Standard: ANSI / ASME B16.9 / MSS SP 43

Size Range: 1/2" - 48" / DN15 - 1200

Thickness Schedule: SCH 10 - SCH 160, XXS

Standard: ANSI / ASME B16.9

We are a manufacturer, supplier and exporter of ASME B16.9 butt weld equal and reducing tee in China.

ANSI / ASME B16.9 steel pipe tee dimensions and weight chart is free for you.

Shape Type: Equal and Reducing

Size Range: 1/2" - 80" / DN15 - 2000

Thickness Schedule: SCH 10 - SCH 160, XXS

Standard: ANSI / ASME B16.9

Type: Long Pattern (LP) and Short Pattern (SP)

Size Range: 1/2” - 24” / DN15 - 600

Thickness Schedule: SCH 10 - SCH 160, XXS

Size Range: 3/4" - 60" / DN20 - 1500

Thickness Schedule: SCH 10 - SCH 160, XXS

Standard: ANSI / ASME B16.9 / MSS SP 43

Size Range: 3/4" - 60" / DN20 - 1500

Thickness Schedule: SCH 10 - SCH 160, XXS

Standard: ANSI / ASME B16.9 & MSS SP-43

Size Range: 1/2" - 48" / DN15 - 1200

Thickness Schedule: SCH 10 - SCH 160, XXS

Standard: ANSI / ASME B16.9

Type: 90 Degree and 45 Degree

Shape: Straight and Reducing Elbow

Size: 1/8” – 4” / DN6 - DN100

Shape: Equal and Reducing Tee

Size: 1/8"- 4" / DN6 - DN100

Pressure: Class 3000LBS, 6000Lbs, 9000lbs.

Standard: ASME B16.11, BS3799

Shape: Equal Cross Tee and Reducing Cross Tee

Size Range: 1/8” – 4” / DN6 - DN100

Pressure Rating: Class 3000lbs, 6000lbs, 9000lbs.

Standard: GB/T 14383, ASME B16.11, BS3799

Type: Full Coupling and Half Coupling

Shape: Straight Coupling and Reducing Coupling

Size Range: 1/8” – 4” / DN6 - DN100

Pressure Rating: Class 3000lbs, 6000lbs, 9000lbs

Size Range: 1/8” - 3” / DN6 - DN80

Pressure Rating: Class 3000lbs

Standard: MSS SP-83

Type: 90 Degree and 45 Degree Elbow

Shape: Straight and Reducing Elbow

Thread Type: NPT, PT, BSPP, BSPT, PF

Shape: Equal and Reducing Tee

Size Range: 1/8” – 4” / DN6 - DN100

Pressure Rating: Class 2000 lbs, 3000 lbs, 6000 lbs

Shape: Equal and Reducing

Size: 1/8" - 4" / DN6 - DN100

Pressure: Class 2000 lbs, 3000 lbs, 6000 lbs

Type: Full and Half Coupling

Shape: Straight and Reducing Coupling

Thread Type: NPT, PT, BSPP, BSPT, PF

Size Range: 1/8” – 4” / DN6 - DN100

Pressure Rating: Class 3000lbs, 6000lbs

Standard: ASME B16.11, BS3799, EN 10241

Size Range: 1/8” - 3” / DN6 - DN80

Pressure Rating: Class 3000lbs

Standard: MSS SP-83

Shape: Threaded One End (TOE) and Threaded Both End (TBE)

Size : 1/4” - 12” / DN8 - DN300

Thickness : Sch 10 - Sch 160 / XXS

Shape: Concentric and Eccentric

Size: 1/4" - 12" / DN8 - DN300

Thickness: Sch 10 - Sch 160 / XXS

Shape: Equal and Reducing

Thread Type: NPT, PT, BSPP, BSPT, PF

Size Range: 1/8” - 3” / DN6 - DN80

Shape: Hex Head, Square Head and Round Head.

Thread Type: NPT, PT, BSPP, BSPT, PF

Size Range: 1/8" - 4" / DN6 - DN100

| Availability: | |

|---|---|

| Quantity: | |

What is a Class 600 Blind Flange

Compared to the cast iron flanges, forged steel flanges have better performance and adaptation in high pressure and temperature environment, the main difference between them is their manufacturing process, forge and cast. By the different ways they are connected to the main pipeline, there are mainly six types of flanges, blind(BL), socket weld(SW), threaded(THD), weld neck(WN),slip on(SO) and lap ring joint(LPJ).

In ASME B16.5 standard, there are several different schedule for the pressure environment the flanges should be applied to, called pressure rating, they are class 150 / 300 /400 /600 /900 /1500 /2500.

Let's conclusion, in description class 600 blind flange, Blind is the flange type, class600 is the pressure rating of the flange.

More Information We Need to Make Sure the Flange

Is it enough for us to manufacture a flange by description “class 600 blind flange”? Of course not.

Usually we need several main factors to totally make sure a flange material, flange type, size, pressure rating (if in WN flange, we still need the thickness of the pipes),the sealing face type, and of course material which has the most influence one on price.

Specification of Forged Steel Flange

Sealing Face | RF, FF, RTJ |

Size Range | 1/2"- 48" / DN15-DN1200 |

Pressure Rating | Class 150, 300, 600, 900, 1500, 2500lb |

Standard | ASME / ANSI B16.5, ASME B16.47 Series A/B |

Carbon Steel | ASTM A105 / A105N |

Low Temp Carbon Steel | ASTM A350 LF2/LF3 |

Pipeline Steel | ASTM A694 F42 / 46 / 56 / 60 / 65 |

Alloy Steel | ASTM A182 F11 / 12 / 5 / 9 / 91 / 92 |

Stainless Steel | ASTM A182 F304/304L/304H, 316/316L, 310S, 317,347,904L |

Duplex Stainless Steel | ASTM A182 F51, F53, F44 |

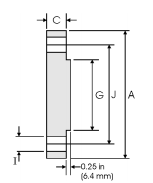

Class 600 Blind Flange Dimension

| Nominal Pipe Size | A | C | G | H | I | J | Weight | |

| Outside Diameter | Overall Diameter | Flange Thickness min | Face Diameter | Number of Holes | Bolt Hole Diameter | Diameter of Circle of Holes | kg/piece | |

| mm | mm | mm | mm | mm | mm | |||

| 1/2 | 21.3 | 95.2 | 14.2 | 35.1 | 4 | 15.7 | 66.55 | 0.76 |

| 3/4 | 26.7 | 117.3 | 15.7 | 42.9 | 4 | 19. 10 | 82.6 | 1.28 |

| 1 | 33.4 | 123.9 | 17.5 | 50.8 | 4 | 19. 10 | 88.9 | 1.60 |

| 11/4 | 42.2 | 133.3 | 20.6 | 63.5 | 4 | 19. 10 | 98.6 | 2.23 |

| 11/2 | 48.3 | 155.4 | 22.3 | 73.15 | 4 | 22.4 | 114.3 | 3.25 |

| 2 | 60.3 | 165. 1 | 25.4 | 91.9 | 8 | 19. 10 | 127 | 4.15 |

| 21/2 | 73 | 190.5 | 28.4 | 104.6 | 8 | 22.4 | 149.4 | 6.13 |

| 3 | 88.9 | 209.5 | 31.7 | 127 | 8 | 22.4 | 168.1 | 8.44 |

| 31/2 | 101.6 | 228.6 | 35 | 139.7 | 8 | 25.4 | 184.2 | 11.0 |

| 4 | 114.3 | 273. 1 | 38.1 | 157.2 | 8 | 25.4 | 215.9 | 17.3 |

| 5 | 141.3 | 330.2 | 44.5 | 185.7 | 8 | 28.4 | 266.7 | 29.4 |

| 6 | 168.3 | 355.6 | 47.8 | 215.9 | 12 | 28.4 | 292.1 | 36.1 |

| 8 | 219. 1 | 419. 1 | 55.6 | 269.7 | 12 | 31.75 | 349.3 | 58.9 |

| 10 | 273 | 508 | 63.5 | 323.9 | 16 | 35. 10 | 431.8 | 97.5 |

| 12 | 323.8 | 558.8 | 66.55 | 381 | 20 | 35. 10 | 489 | 124 |

| 14 | 355.6 | 603.3 | 69.85 | 412.8 | 20 | 38. 10 | 527.1 | 151 |

| 16 | 406.4 | 685.8 | 76.2 | 469.9 | 20 | 41. 10 | 603.3 | 214 |

| 18 | 457.2 | 743 | 82.6 | 533.4 | 20 | 44.5 | 654.1 | 272 |

| 20 | 508.0 | 812.8 | 88.9 | 584.2 | 24 | 44.5 | 723.9 | 349 |

| 24 | 609.6 | 939.8 | 101.6 | 692.2 | 24 | 50.8 | 838.2 | 533 |

American Manufacturing Standard of forged steel flanges

We can usually see ASME B 16.5 in a flange's description, which is the main standard for all forges steel flanges, but at some time we will also see ASME B 16.48 or ASME B 16.47 A/B, what are they?

ASME B 16.48 is the standard for a special kind of flange, they will be taken as fittings some times, which are spectacle blind, spade and spacer.

ASME B 16.47 A/B is the standard for flanges whose size is larger than 24 inches , there are two main series A and B in the standard, which is different by their usage in pipeline or valves. On thing you need to notice is this standard only cover blind flange and weld neck flange, if there are other types of flange bigger than 24 inches, we will need a drawing to manufacture it.

Sealing Face for Blind Flange

There are three types sealing face for blind flange as below:

The raised face (RF) is the most common type of flange facing used. It is called a raised face flange because it has a raised surface above the bolting circle where the gasket is placed. These flanges are widely used in oil and gas pipelines.

Flat face (FF) flanges are similar to the RF flanges, but they do not have the raised area like the RF flange. Instead, the whole surface is flat.

A Ring type joint flange(RTJ) is a machined metallic ring with a deep groove cut into its face. This groove rests a metal ring which gets compressed when the connecting bolts of the flange are tightened.

What is Class 600 Blind Flange Used

A blind flange is a solid disk used to block off a pipeline or to create a stop. Similar to a regular flange, a blind flange has mounting holes around the perimeter and the gasket sealing rings are machined into the mating surface. The difference is that a blind flange has no opening for fluids to pass through.

What is a Class 600 Blind Flange

Compared to the cast iron flanges, forged steel flanges have better performance and adaptation in high pressure and temperature environment, the main difference between them is their manufacturing process, forge and cast. By the different ways they are connected to the main pipeline, there are mainly six types of flanges, blind(BL), socket weld(SW), threaded(THD), weld neck(WN),slip on(SO) and lap ring joint(LPJ).

In ASME B16.5 standard, there are several different schedule for the pressure environment the flanges should be applied to, called pressure rating, they are class 150 / 300 /400 /600 /900 /1500 /2500.

Let's conclusion, in description class 600 blind flange, Blind is the flange type, class600 is the pressure rating of the flange.

More Information We Need to Make Sure the Flange

Is it enough for us to manufacture a flange by description “class 600 blind flange”? Of course not.

Usually we need several main factors to totally make sure a flange material, flange type, size, pressure rating (if in WN flange, we still need the thickness of the pipes),the sealing face type, and of course material which has the most influence one on price.

Specification of Forged Steel Flange

Sealing Face | RF, FF, RTJ |

Size Range | 1/2"- 48" / DN15-DN1200 |

Pressure Rating | Class 150, 300, 600, 900, 1500, 2500lb |

Standard | ASME / ANSI B16.5, ASME B16.47 Series A/B |

Carbon Steel | ASTM A105 / A105N |

Low Temp Carbon Steel | ASTM A350 LF2/LF3 |

Pipeline Steel | ASTM A694 F42 / 46 / 56 / 60 / 65 |

Alloy Steel | ASTM A182 F11 / 12 / 5 / 9 / 91 / 92 |

Stainless Steel | ASTM A182 F304/304L/304H, 316/316L, 310S, 317,347,904L |

Duplex Stainless Steel | ASTM A182 F51, F53, F44 |

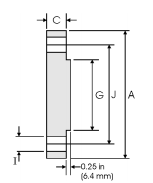

Class 600 Blind Flange Dimension

| Nominal Pipe Size | A | C | G | H | I | J | Weight | |

| Outside Diameter | Overall Diameter | Flange Thickness min | Face Diameter | Number of Holes | Bolt Hole Diameter | Diameter of Circle of Holes | kg/piece | |

| mm | mm | mm | mm | mm | mm | |||

| 1/2 | 21.3 | 95.2 | 14.2 | 35.1 | 4 | 15.7 | 66.55 | 0.76 |

| 3/4 | 26.7 | 117.3 | 15.7 | 42.9 | 4 | 19. 10 | 82.6 | 1.28 |

| 1 | 33.4 | 123.9 | 17.5 | 50.8 | 4 | 19. 10 | 88.9 | 1.60 |

| 11/4 | 42.2 | 133.3 | 20.6 | 63.5 | 4 | 19. 10 | 98.6 | 2.23 |

| 11/2 | 48.3 | 155.4 | 22.3 | 73.15 | 4 | 22.4 | 114.3 | 3.25 |

| 2 | 60.3 | 165. 1 | 25.4 | 91.9 | 8 | 19. 10 | 127 | 4.15 |

| 21/2 | 73 | 190.5 | 28.4 | 104.6 | 8 | 22.4 | 149.4 | 6.13 |

| 3 | 88.9 | 209.5 | 31.7 | 127 | 8 | 22.4 | 168.1 | 8.44 |

| 31/2 | 101.6 | 228.6 | 35 | 139.7 | 8 | 25.4 | 184.2 | 11.0 |

| 4 | 114.3 | 273. 1 | 38.1 | 157.2 | 8 | 25.4 | 215.9 | 17.3 |

| 5 | 141.3 | 330.2 | 44.5 | 185.7 | 8 | 28.4 | 266.7 | 29.4 |

| 6 | 168.3 | 355.6 | 47.8 | 215.9 | 12 | 28.4 | 292.1 | 36.1 |

| 8 | 219. 1 | 419. 1 | 55.6 | 269.7 | 12 | 31.75 | 349.3 | 58.9 |

| 10 | 273 | 508 | 63.5 | 323.9 | 16 | 35. 10 | 431.8 | 97.5 |

| 12 | 323.8 | 558.8 | 66.55 | 381 | 20 | 35. 10 | 489 | 124 |

| 14 | 355.6 | 603.3 | 69.85 | 412.8 | 20 | 38. 10 | 527.1 | 151 |

| 16 | 406.4 | 685.8 | 76.2 | 469.9 | 20 | 41. 10 | 603.3 | 214 |

| 18 | 457.2 | 743 | 82.6 | 533.4 | 20 | 44.5 | 654.1 | 272 |

| 20 | 508.0 | 812.8 | 88.9 | 584.2 | 24 | 44.5 | 723.9 | 349 |

| 24 | 609.6 | 939.8 | 101.6 | 692.2 | 24 | 50.8 | 838.2 | 533 |

American Manufacturing Standard of forged steel flanges

We can usually see ASME B 16.5 in a flange's description, which is the main standard for all forges steel flanges, but at some time we will also see ASME B 16.48 or ASME B 16.47 A/B, what are they?

ASME B 16.48 is the standard for a special kind of flange, they will be taken as fittings some times, which are spectacle blind, spade and spacer.

ASME B 16.47 A/B is the standard for flanges whose size is larger than 24 inches , there are two main series A and B in the standard, which is different by their usage in pipeline or valves. On thing you need to notice is this standard only cover blind flange and weld neck flange, if there are other types of flange bigger than 24 inches, we will need a drawing to manufacture it.

Sealing Face for Blind Flange

There are three types sealing face for blind flange as below:

The raised face (RF) is the most common type of flange facing used. It is called a raised face flange because it has a raised surface above the bolting circle where the gasket is placed. These flanges are widely used in oil and gas pipelines.

Flat face (FF) flanges are similar to the RF flanges, but they do not have the raised area like the RF flange. Instead, the whole surface is flat.

A Ring type joint flange(RTJ) is a machined metallic ring with a deep groove cut into its face. This groove rests a metal ring which gets compressed when the connecting bolts of the flange are tightened.

What is Class 600 Blind Flange Used

A blind flange is a solid disk used to block off a pipeline or to create a stop. Similar to a regular flange, a blind flange has mounting holes around the perimeter and the gasket sealing rings are machined into the mating surface. The difference is that a blind flange has no opening for fluids to pass through.