Size Range: 1/2" - 80" / DN15 - 2000

Thickness Schedule: SCH 10 - SCH 160, XXS

Standard: ANSI / ASME B16.9 / MSS SP 43

Size Range: 1/2" - 80" / DN15 - 2000

Thickness Schedule: SCH 10 - SCH 160, XXS

Standard: ANSI / ASME B16.9 / MSS SP 43

Size Range: 1/2" - 48" / DN15 - 1200

Thickness Schedule: SCH 10 - SCH 160, XXS

Standard: ANSI / ASME B16.9

We are a manufacturer, supplier and exporter of ASME B16.9 butt weld equal and reducing tee in China.

ANSI / ASME B16.9 steel pipe tee dimensions and weight chart is free for you.

Shape Type: Equal and Reducing

Size Range: 1/2" - 80" / DN15 - 2000

Thickness Schedule: SCH 10 - SCH 160, XXS

Standard: ANSI / ASME B16.9

Type: Long Pattern (LP) and Short Pattern (SP)

Size Range: 1/2” - 24” / DN15 - 600

Thickness Schedule: SCH 10 - SCH 160, XXS

Size Range: 3/4" - 60" / DN20 - 1500

Thickness Schedule: SCH 10 - SCH 160, XXS

Standard: ANSI / ASME B16.9 / MSS SP 43

Size Range: 3/4" - 60" / DN20 - 1500

Thickness Schedule: SCH 10 - SCH 160, XXS

Standard: ANSI / ASME B16.9 & MSS SP-43

Size Range: 1/2" - 48" / DN15 - 1200

Thickness Schedule: SCH 10 - SCH 160, XXS

Standard: ANSI / ASME B16.9

Type: 90 Degree and 45 Degree

Shape: Straight and Reducing Elbow

Size: 1/8” – 4” / DN6 - DN100

Shape: Equal and Reducing Tee

Size: 1/8"- 4" / DN6 - DN100

Pressure: Class 3000LBS, 6000Lbs, 9000lbs.

Standard: ASME B16.11, BS3799

Shape: Equal Cross Tee and Reducing Cross Tee

Size Range: 1/8” – 4” / DN6 - DN100

Pressure Rating: Class 3000lbs, 6000lbs, 9000lbs.

Standard: GB/T 14383, ASME B16.11, BS3799

Type: Full Coupling and Half Coupling

Shape: Straight Coupling and Reducing Coupling

Size Range: 1/8” – 4” / DN6 - DN100

Pressure Rating: Class 3000lbs, 6000lbs, 9000lbs

Size Range: 1/8” - 3” / DN6 - DN80

Pressure Rating: Class 3000lbs

Standard: MSS SP-83

Type: 90 Degree and 45 Degree Elbow

Shape: Straight and Reducing Elbow

Thread Type: NPT, PT, BSPP, BSPT, PF

Shape: Equal and Reducing Tee

Size Range: 1/8” – 4” / DN6 - DN100

Pressure Rating: Class 2000 lbs, 3000 lbs, 6000 lbs

Shape: Equal and Reducing

Size: 1/8" - 4" / DN6 - DN100

Pressure: Class 2000 lbs, 3000 lbs, 6000 lbs

Type: Full and Half Coupling

Shape: Straight and Reducing Coupling

Thread Type: NPT, PT, BSPP, BSPT, PF

Size Range: 1/8” – 4” / DN6 - DN100

Pressure Rating: Class 3000lbs, 6000lbs

Standard: ASME B16.11, BS3799, EN 10241

Size Range: 1/8” - 3” / DN6 - DN80

Pressure Rating: Class 3000lbs

Standard: MSS SP-83

Shape: Threaded One End (TOE) and Threaded Both End (TBE)

Size : 1/4” - 12” / DN8 - DN300

Thickness : Sch 10 - Sch 160 / XXS

Shape: Concentric and Eccentric

Size: 1/4" - 12" / DN8 - DN300

Thickness: Sch 10 - Sch 160 / XXS

Shape: Equal and Reducing

Thread Type: NPT, PT, BSPP, BSPT, PF

Size Range: 1/8” - 3” / DN6 - DN80

Shape: Hex Head, Square Head and Round Head.

Thread Type: NPT, PT, BSPP, BSPT, PF

Size Range: 1/8" - 4" / DN6 - DN100

| Availability: | |

|---|---|

| Quantity: | |

What is Socket Fitting

Socket weld is one type of high pressure forged fittings. It is used for inserted into a recessed area of a valve, fitting or flange. Once correctly inserted, fillet type sealing welds are applied to join the pipe to the fitting.

Same as threaded fittings, they are mainly used for small pipe diameters (Small Bore Piping); generally, for piping whose nominal diameter is NPS 2 or smaller.

These fittings are commonly called SW pipe fittings that include elbows, tees, cross, caps, coupling and union.

Pressure

There are three types pressure rate for the socket weld coupling, class 3000, 6000 and 9000.

The pressure rate means the pressure the coupling can bear, such as class6000 socket weld coupling can bear 6000LB pressure, and match with the same or lower pressure pipes and pipe fittings.

Size

The size range is 1/8" – 4" / DN6 - DN100 for the Class6000 socket weld coupling. The most common size is below 2". It means most socket weld coupling in stock is below 2". We usually manufacture the coupling when the size is big than 2".

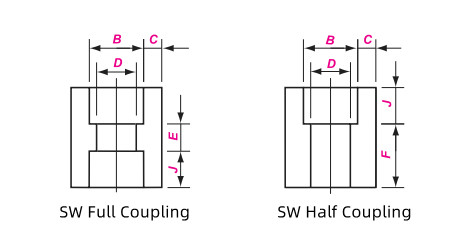

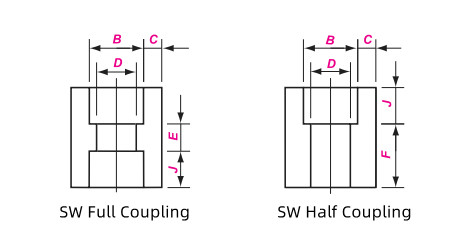

Half Coupling and Full Coupling

Full Socket Weld Coupling

Half Socket Weld Coupling

Half coupling is only socket weld at one end, and the other end can be welded directly into the operation of the pipe to form a branch connection. It is a joint that helps to extend or terminate a pipe. On the other hand, full coupling have both ends of threaded or socket welded.

ASME B16.11 Socket Weld Coupling Dimensions

DN | NPS | B | D | C | |||||||

| 3000 | 6000 | 9000 | 3000 | 6000 | 9000 | ||||||

| 6 | 1/8 | 10.9 | 6.1 | 3.2 | - | 3.18 | 3.18 | 3.96 | 3.43 | - | - |

| 8 | 1/4 | 14.3 | 8.5 | 5.6 | - | 3.78 | 3.30 | 4.60 | 4.01 | - | - |

| 10 | 3/8 | 17.7 | 11.8 | 8.4 | - | 4.01 | 3.50 | 5.03 | 4.37 | - | - |

| 15 | 1/2 | 21.9 | 15.0 | 11.0 | 5.6 | 4.67 | 4.09 | 5.97 | 5.18 | 9.53 | 8.18 |

| 20 | 3/4 | 27.3 | 20.2 | 14.8 | 10.3 | 4.90 | 4.27 | 6.96 | 6.04 | 9.78 | 8.56 |

| 25 | 1 | 34.0 | 25.9 | 19.9 | 14.4 | 5.69 | 4.98 | 7.92 | 6.93 | 11.38 | 9.96 |

| 32 | 11/4 | 42.8 | 34.3 | 28.7 | 22.0 | 6.07 | 5.28 | 7.92 | 6.93 | 12.14 | 10.62 |

| 40 | 11/2 | 48.9 | 40.1 | 33.2 | 27.2 | 6.35 | 5.54 | 8.92 | 7.80 | 12.7 | 11.12 |

| 50 | 2 | 61.2 | 51.7 | 42.1 | 37.4 | 6.93 | 6.04 | 10.92 | 9.50 | 13.84 | 12.12 |

| 65 | 21/2 | 73.9 | 61.2 | - | - | 8.76 | 7.62 | - | - | - | - |

| 80 | 3 | 89.9 | 76.4 | - | - | 9.52 | 8.30 | - | - | - | - |

| 100 | 4 | 115.5 | 100.7 | - | - | 10.69 | 9.35 | - | - | - | - |

Weight For Class 6000 Socket Weld Coupling

Nominal Size | SW Coupling Weight | |

DN | NPS | 6000 |

6 | 1/8 | 0.06 |

15 | 1/2 | 0.16 |

32 | 11/4 | 0.65 |

65 | 21/2 | - |

Inspection

PMI test

Dimension Test

Visual Test

Hydrostatic test

Flattening Test

We always inspect the goods when delivery. For the Class 6000 socket weld coupling, we inspect OD, wall thickness, height.

For the stainless steel fittings, we will also make PMI inspection.

Advantages of Socket Weld Coupling

Reasonable Sealing Structure Design: Socket weld coupling usually adopt special sealing structures, such as rubber sealing rings. When the pipe is inserted into the socket, the sealing ring will fit tightly between the outer wall of the pipe and the inner wall of the socket to form an effective seal. This sealing structure can effectively prevent the leakage of the medium in the pipeline, and maintain good sealing performance even under harsh working conditions such as high pressure, high temperature or vibration.

Adapt to a Variety of Media: Due to its good sealing performance, the socket weld coupling is suitable for pipe connections that transport various media, including water, gas, oil, etc. Whether in the chemical, petroleum, natural gas and other industries, or in the fields of building water supply and drainage, fire protection, etc., the socket weld coupling can meet the transportation requirements of different media and ensure the safe operation of the pipeline system.

Strong Adaptability to Pipe Diameter: The socket weld coupling can be used for pipe connections of different diameters. From small-diameter household pipes to large industrial pipes, there are corresponding specifications of pipe clamps to choose from.

Good material compatibility: The socket weld coupling can be used with pipes of various materials, such as steel pipes, plastic pipes, cast iron pipes, etc.

What is Socket Fitting

Socket weld is one type of high pressure forged fittings. It is used for inserted into a recessed area of a valve, fitting or flange. Once correctly inserted, fillet type sealing welds are applied to join the pipe to the fitting.

Same as threaded fittings, they are mainly used for small pipe diameters (Small Bore Piping); generally, for piping whose nominal diameter is NPS 2 or smaller.

These fittings are commonly called SW pipe fittings that include elbows, tees, cross, caps, coupling and union.

Pressure

There are three types pressure rate for the socket weld coupling, class 3000, 6000 and 9000.

The pressure rate means the pressure the coupling can bear, such as class6000 socket weld coupling can bear 6000LB pressure, and match with the same or lower pressure pipes and pipe fittings.

Size

The size range is 1/8" – 4" / DN6 - DN100 for the Class6000 socket weld coupling. The most common size is below 2". It means most socket weld coupling in stock is below 2". We usually manufacture the coupling when the size is big than 2".

Half Coupling and Full Coupling

Full Socket Weld Coupling

Half Socket Weld Coupling

Half coupling is only socket weld at one end, and the other end can be welded directly into the operation of the pipe to form a branch connection. It is a joint that helps to extend or terminate a pipe. On the other hand, full coupling have both ends of threaded or socket welded.

ASME B16.11 Socket Weld Coupling Dimensions

DN | NPS | B | D | C | |||||||

| 3000 | 6000 | 9000 | 3000 | 6000 | 9000 | ||||||

| 6 | 1/8 | 10.9 | 6.1 | 3.2 | - | 3.18 | 3.18 | 3.96 | 3.43 | - | - |

| 8 | 1/4 | 14.3 | 8.5 | 5.6 | - | 3.78 | 3.30 | 4.60 | 4.01 | - | - |

| 10 | 3/8 | 17.7 | 11.8 | 8.4 | - | 4.01 | 3.50 | 5.03 | 4.37 | - | - |

| 15 | 1/2 | 21.9 | 15.0 | 11.0 | 5.6 | 4.67 | 4.09 | 5.97 | 5.18 | 9.53 | 8.18 |

| 20 | 3/4 | 27.3 | 20.2 | 14.8 | 10.3 | 4.90 | 4.27 | 6.96 | 6.04 | 9.78 | 8.56 |

| 25 | 1 | 34.0 | 25.9 | 19.9 | 14.4 | 5.69 | 4.98 | 7.92 | 6.93 | 11.38 | 9.96 |

| 32 | 11/4 | 42.8 | 34.3 | 28.7 | 22.0 | 6.07 | 5.28 | 7.92 | 6.93 | 12.14 | 10.62 |

| 40 | 11/2 | 48.9 | 40.1 | 33.2 | 27.2 | 6.35 | 5.54 | 8.92 | 7.80 | 12.7 | 11.12 |

| 50 | 2 | 61.2 | 51.7 | 42.1 | 37.4 | 6.93 | 6.04 | 10.92 | 9.50 | 13.84 | 12.12 |

| 65 | 21/2 | 73.9 | 61.2 | - | - | 8.76 | 7.62 | - | - | - | - |

| 80 | 3 | 89.9 | 76.4 | - | - | 9.52 | 8.30 | - | - | - | - |

| 100 | 4 | 115.5 | 100.7 | - | - | 10.69 | 9.35 | - | - | - | - |

Weight For Class 6000 Socket Weld Coupling

Nominal Size | SW Coupling Weight | |

DN | NPS | 6000 |

6 | 1/8 | 0.06 |

15 | 1/2 | 0.16 |

32 | 11/4 | 0.65 |

65 | 21/2 | - |

Inspection

PMI test

Dimension Test

Visual Test

Hydrostatic test

Flattening Test

We always inspect the goods when delivery. For the Class 6000 socket weld coupling, we inspect OD, wall thickness, height.

For the stainless steel fittings, we will also make PMI inspection.

Advantages of Socket Weld Coupling

Reasonable Sealing Structure Design: Socket weld coupling usually adopt special sealing structures, such as rubber sealing rings. When the pipe is inserted into the socket, the sealing ring will fit tightly between the outer wall of the pipe and the inner wall of the socket to form an effective seal. This sealing structure can effectively prevent the leakage of the medium in the pipeline, and maintain good sealing performance even under harsh working conditions such as high pressure, high temperature or vibration.

Adapt to a Variety of Media: Due to its good sealing performance, the socket weld coupling is suitable for pipe connections that transport various media, including water, gas, oil, etc. Whether in the chemical, petroleum, natural gas and other industries, or in the fields of building water supply and drainage, fire protection, etc., the socket weld coupling can meet the transportation requirements of different media and ensure the safe operation of the pipeline system.

Strong Adaptability to Pipe Diameter: The socket weld coupling can be used for pipe connections of different diameters. From small-diameter household pipes to large industrial pipes, there are corresponding specifications of pipe clamps to choose from.

Good material compatibility: The socket weld coupling can be used with pipes of various materials, such as steel pipes, plastic pipes, cast iron pipes, etc.